Technical changes for purposes of a technical advancement as well as deviation in colour, errors and printing mistakes are reserved. 3

Index

1. Summary of the balancing machine.................................................................... 4

A. Brief introduction of appearance ................................................................. 4

B. Performance and characteristics................................................................. 5

C. Technical data table ...................................................................................... 6

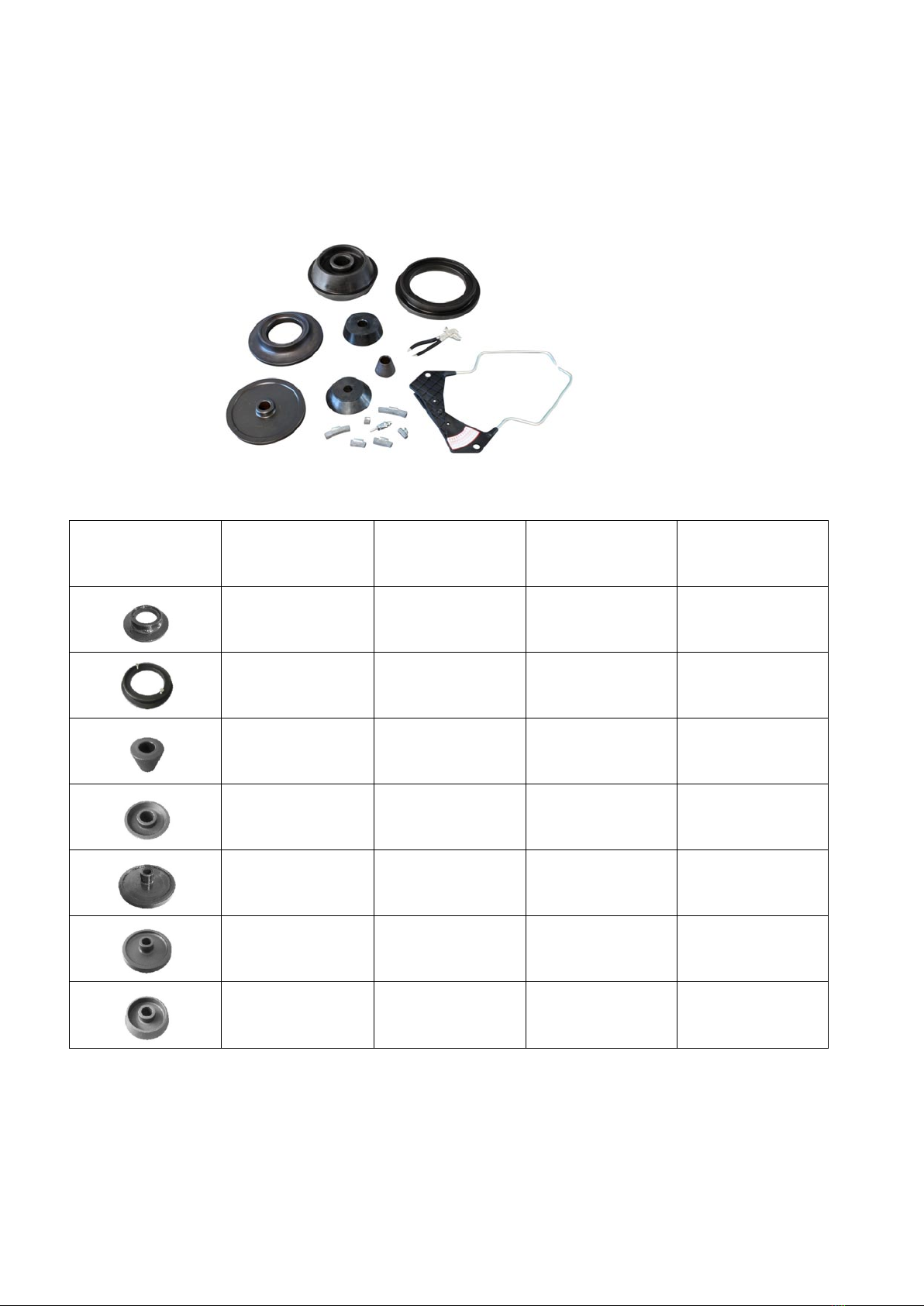

2. Accessories accompanying machines. .........................................................6 - 7

3. Use of balancing machine.................................................................................... 8

A. Attention before using .................................................................................. 8

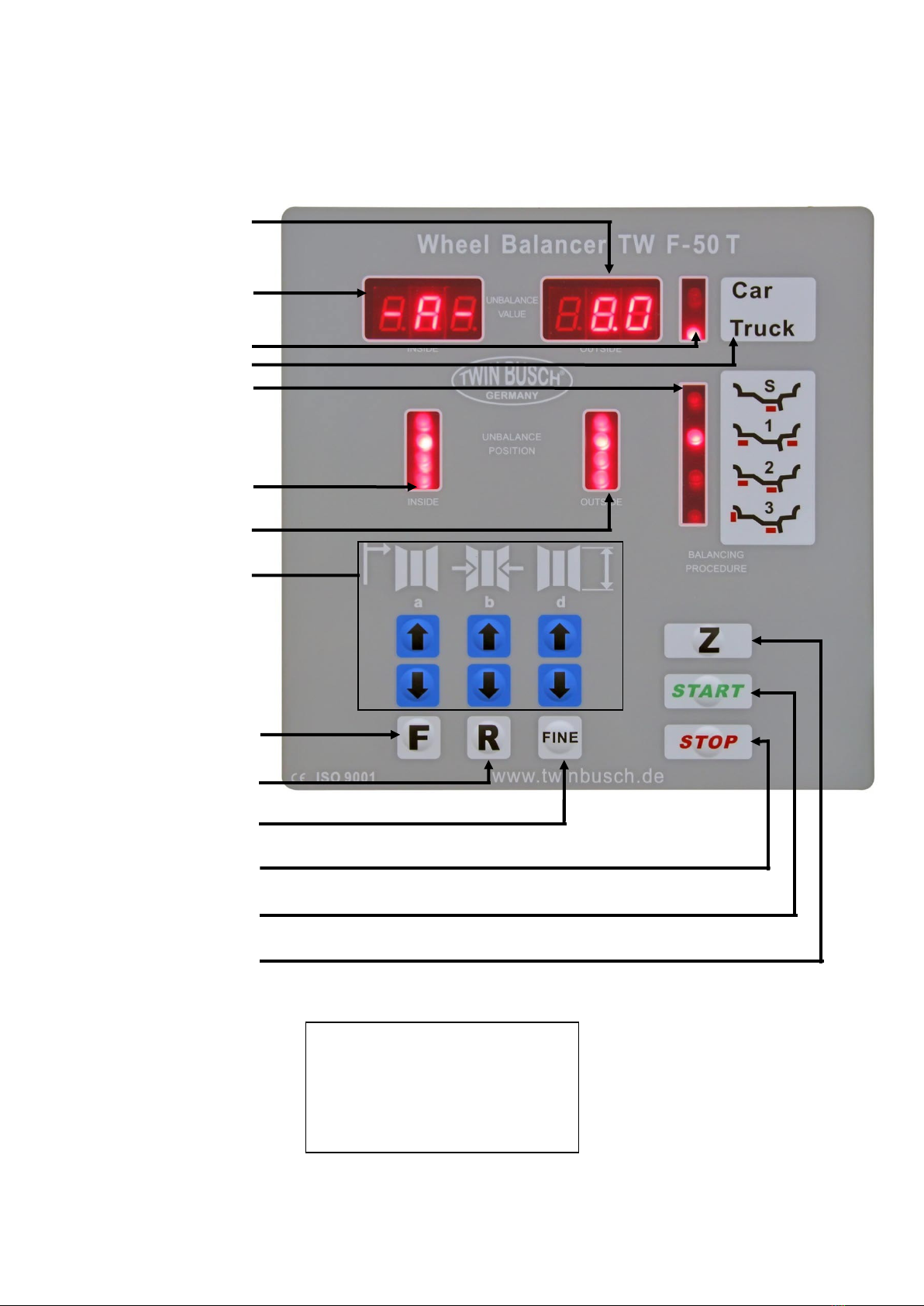

B. Introduction of panel..................................................................................... 9

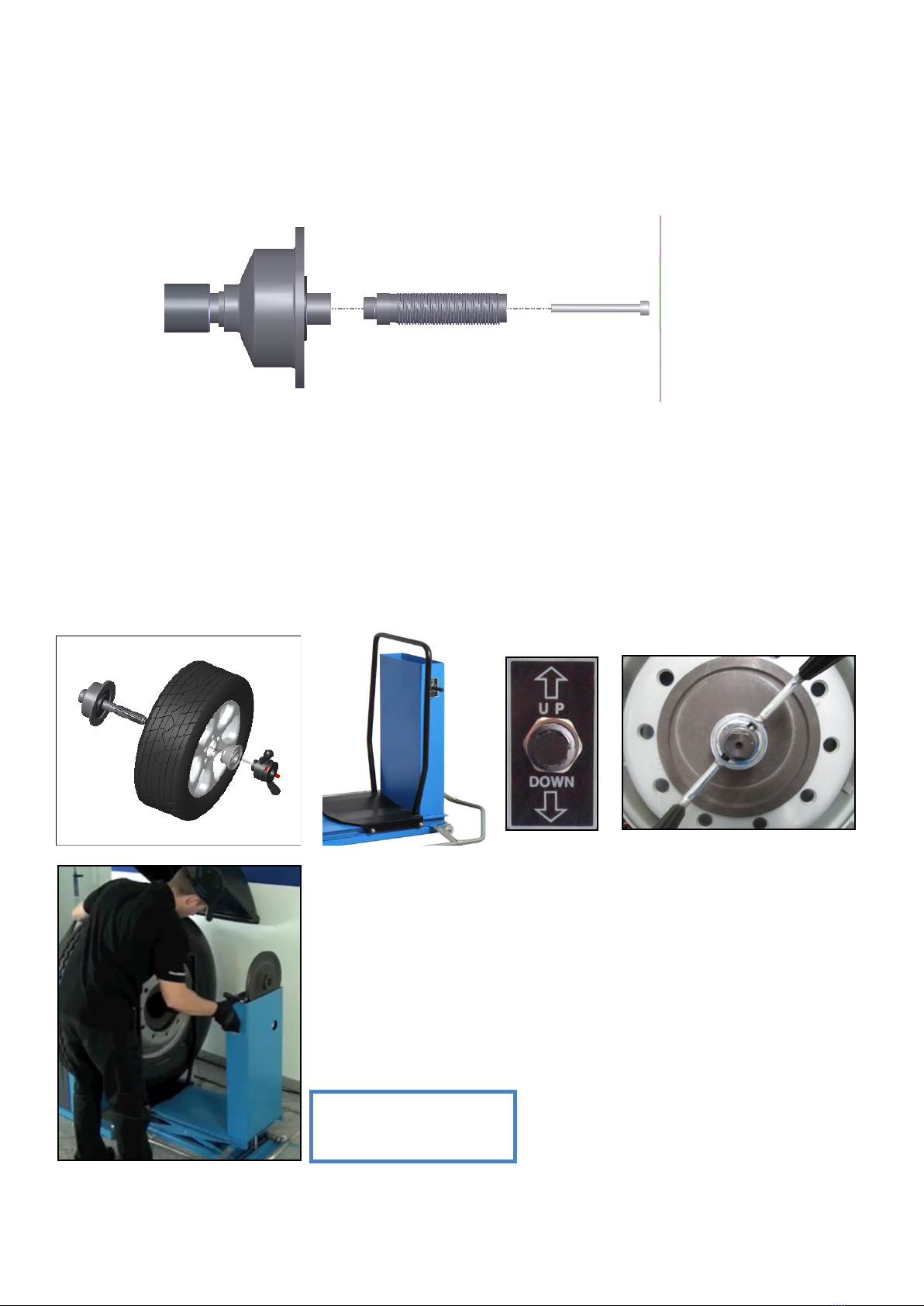

C. Mount the thread axle to the drive shaft / Fix wheel................................. 10

D. Putting through the power and number input............................................1 1

E. Size imput / Balancing examples ............................................................... 12

F. Precautions / Balancing experiences / Self correction.......................13- 15

4. Diagnosis of automatic trouble.......................................................................... 16

5. Options for mode of balancing .......................................................................... 17

6. Circiut diagram (220 V)....................................................................................... 18

7. Circiut diagram (400 V)....................................................................................... 19

8. Exploded drawings .................................................................................... 20 - 22

9. Spare part list ............................................................................................ 23 - 25

10. Space for notes ................................................................................................ 26

11. EG-declaration ................................................................................................. 27

12. Video link (QR code) ....................................................................................... 28