Instruction Sheet

DYNA- CRIMP* 408--2452

LOC B

1of 4

E2010 Tyco Electronics Corporation, Berwyn, PA

All Rights Reserved

TE logo and Tyco Electronics are trademarks.

*Trademark. Other product names, logos, or company names might be trademarks of their respective owners.

TOOLING ASSISTANCE CENTER 1--800--722--1111

PRODUCT INFORMATION 1--800--522--6752

This controlled document is subject to change.

For latest revision and Regional Customer Service,

visit our website at www.tycoelectronics.com

24 MAR 10 Rev DHydraulic Crimping Head 69065

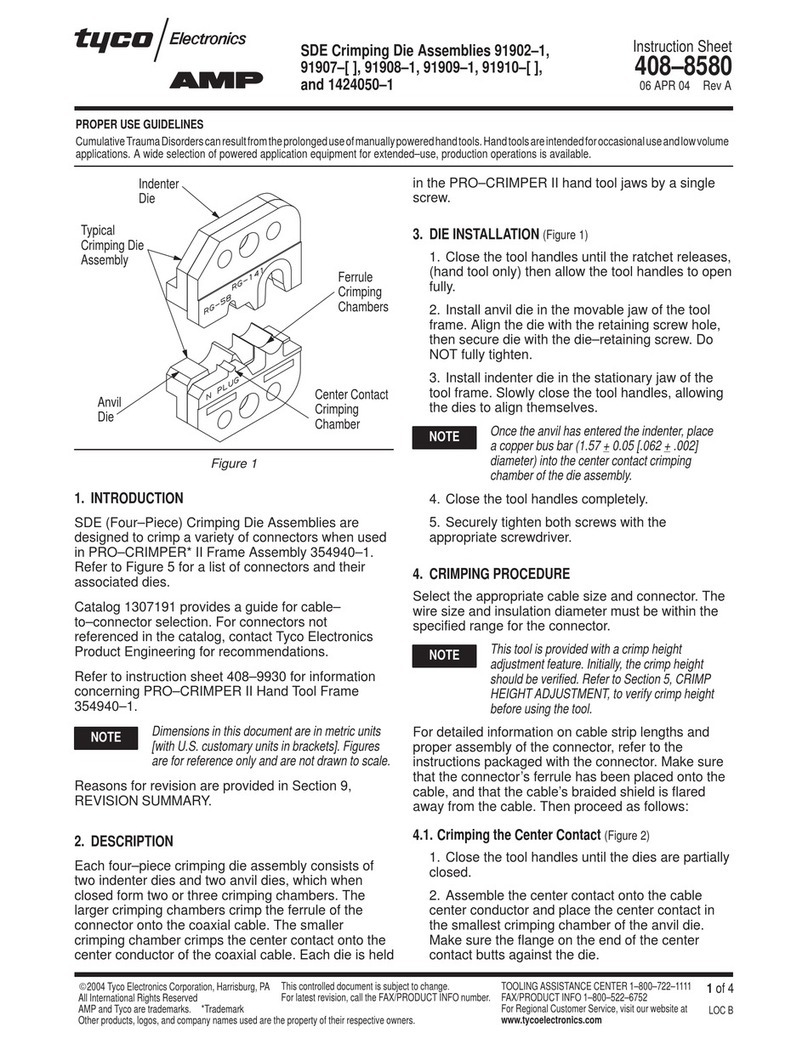

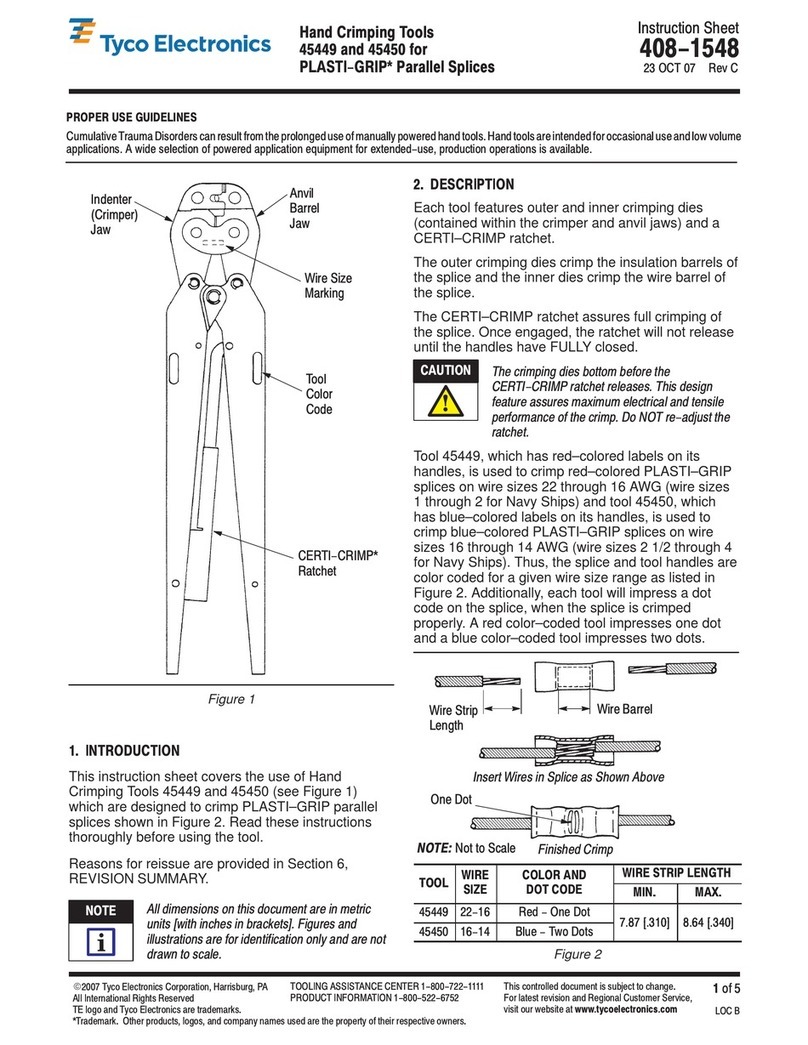

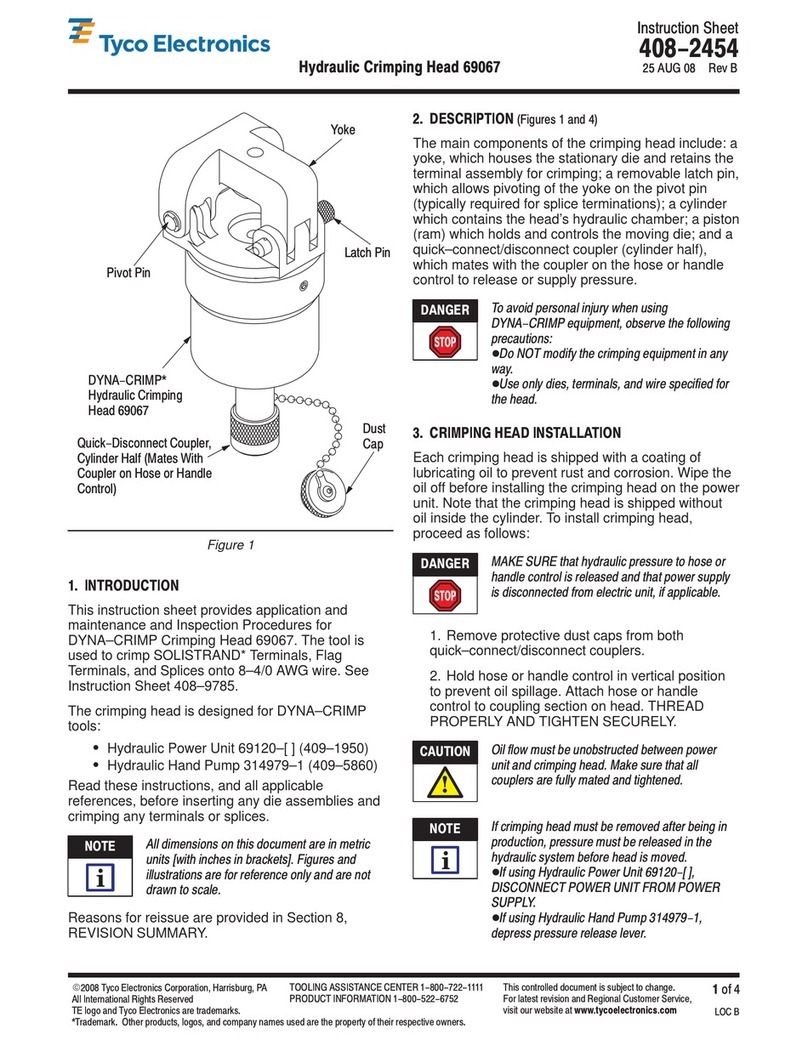

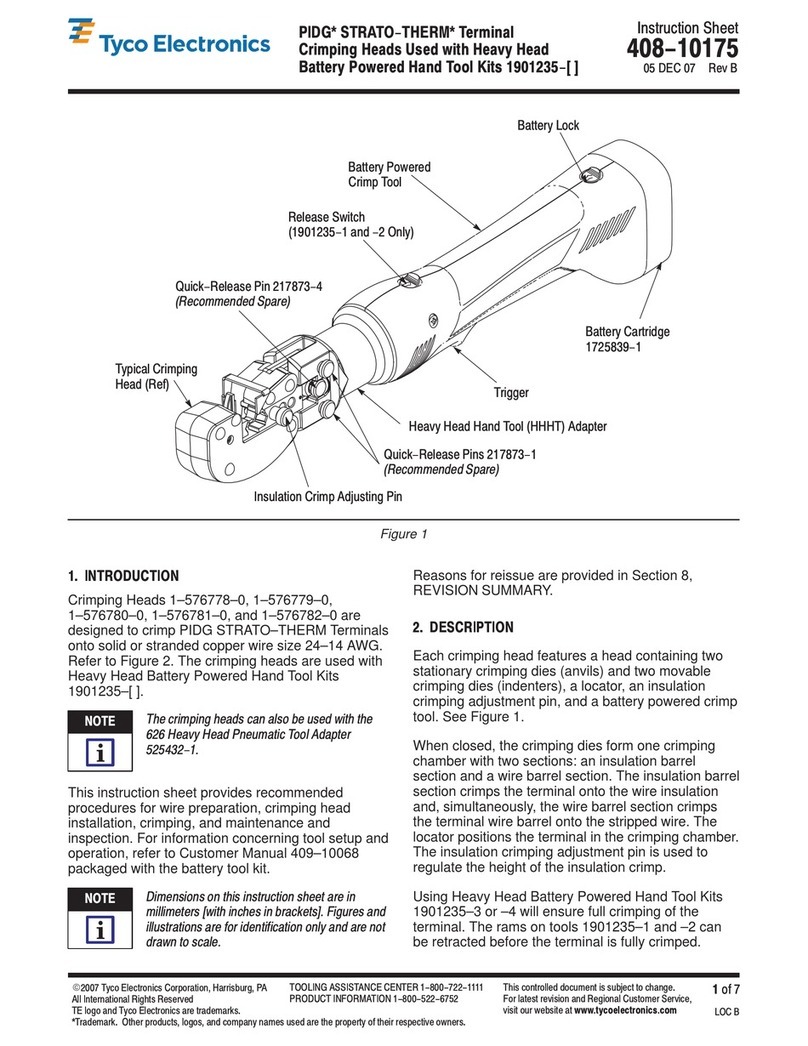

Figure 1

Latch

Pin

Dust Cap

Yoke

Pivot Pin

Quick--Disconnect Coupler,

Cylinder Half (Mates with Coupler

on Hose or Handle Control)

1. INTRODUCTION

This instruction sheet provides application,

maintenance, and inspection procedures for

DYNA--CRIMP Crimping Head 69065 (shown

Figure 1). The crimping head is used to crimp:

SAMPOWER* terminals and splices onto solid or

stranded copper wire sizes 2 through 4/0 AWG.

See instruction sheet 408--1565.

SSOLISTRAND* terminals and splices onto solid

or stranded copper wire sizes 8 through

4/0 AWG. See instruction sheet 408--9786.

The crimping head is designed for two DYNA--CRIMP

tools: either Hydraulic Hand Pump 314979--1 covered

in customer manual 409--5860 or Hydraulic Power

Unit 69120--[ ] described in customer manual

409--1950. Read these instructions, and all applicable

references, before inserting any die assemblies and

crimping any terminals or splices.

Dimensions on this sheet are in millimeters [with

inches in brackets]. Figures and illustrations are

not drawn to scale and are for reference only.

Reasons for reissue of this instruction sheet are

provided in Section 8, REVISION SUMMARY.

2. DESCRIPTION

The main components of the crimping head are: a

yoke which houses the stationary die and retains the

terminal assembly for crimping, a removable latch pin

which allows pivoting of the yoke on the pivot pin

(typically required for splice terminations), a cylinder

which contains the head hydraulic chamber, a piston

(ram) which holds and controls the moving die, and a

quick connect/disconnect coupler (cylinder half) which

mates with the coupler on hose or handle control to

release or supply pressure.

To avoid injury when using DYNA--CRIMP

equipment, observe the following precautions:

-- Do NOT modify the crimping equipment in any

way.

-- Use only dies, terminals, and wire specified for

the crimping head.

-- Do NOT perform repairs other than those

specified in the instructional material supplied

with the equipment.

3. CRIMPING HEAD INSTALLATION

Each crimping head is shipped with a coating of

lubricating oil to prevent rust and corrosion. Wipe the

oil off before installing the crimping head on the power

unit. Note that the crimping head is shipped without

oil inside the cylinder. To install the crimping head,

proceed as follows.

Make sure that hydraulic pressure to hose or

handle control is released and that power supply

is disconnected to electric power unit, if

applicable.

1. Remove protective dust caps from both quick

connect/disconnect couplers.

2. Hold hose or handle control vertically to prevent

oil spillage. Attach hose or handle control to

coupling section on head. Thread properly and

tighten securely.

Oil flow must be unobstructed between power

unit and crimping head. Make sure that all

couplers are fully mated and tightened.

If crimping head must be removed after being in

production, pressure must be released in the

hydraulic system before head is removed.

-- If using Hydraulic Power Unit 69120--[ ],

DISCONNECT POWER UNIT FROM POWER

SUPPLY.

-- If using Hydraulic Hand Pump 314979--1,

activate the pressure release lever.

ORIGINAL INSTRUCTIONS

NOTE

i

DANGER

DANGER

CAUTION

!

DANGER