Instruction Sheet

SDE Crimping Die Assemblies 91902–1,

91907–[ ], 91908–1, 91909–1, 91910–[ ], 408–8580

E

2004 Tyco Electronics Corporation, Harrisburg, PA

AllInternationalRightsReserved

AMP and Tyco are trademarks. *Trademark

Other products, logos, and company names used are the property of their respective owners. LOC B

1 of 4

TOOLINGASSISTANCECENTER1–800–722–1111

FAX/PRODUCT INFO1–800–522–6752

For Regional Customer Service, visit our website at

www.tycoelectronics.com

This controlled document is subject to change.

For latest revision, call the FAX/PRODUCT INFO number.

06 APR 04 Rev A

and 1424050–1

PROPER USE GUIDELINES

CumulativeTraumaDisorderscanresultfromtheprolongeduseofmanuallypoweredhandtools.Handtoolsareintendedforoccasionaluseandlowvolume

applications. A wide selection of powered application equipment for extended–use, production operations is available.

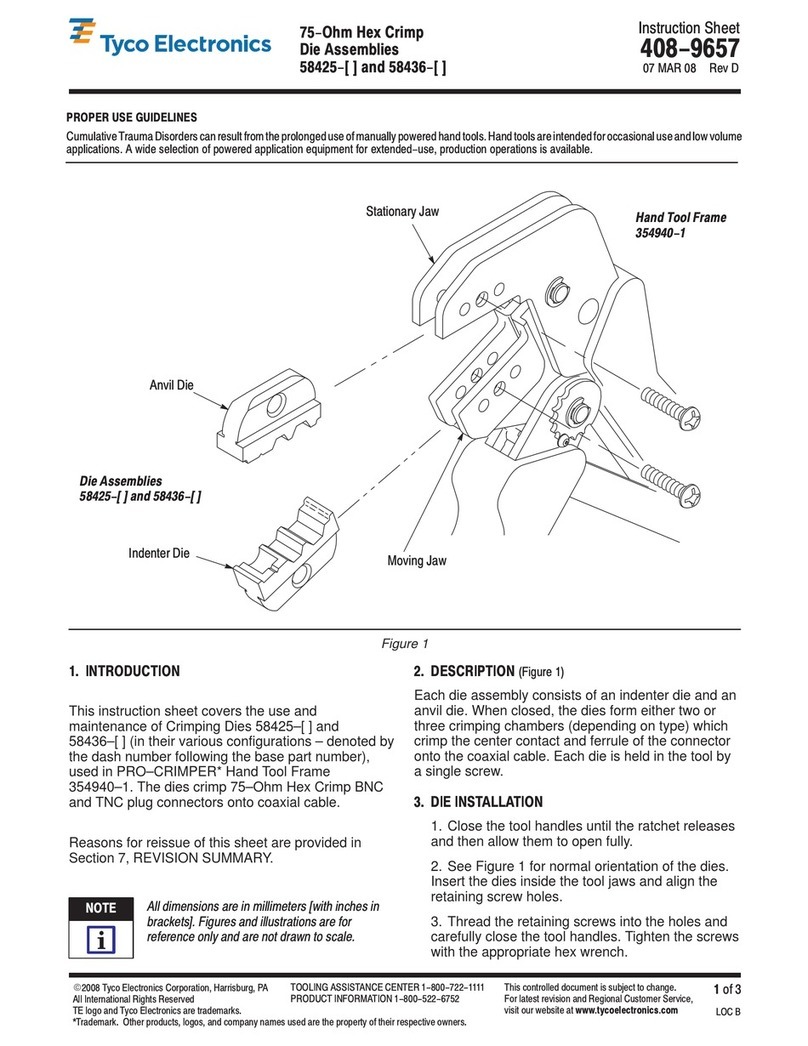

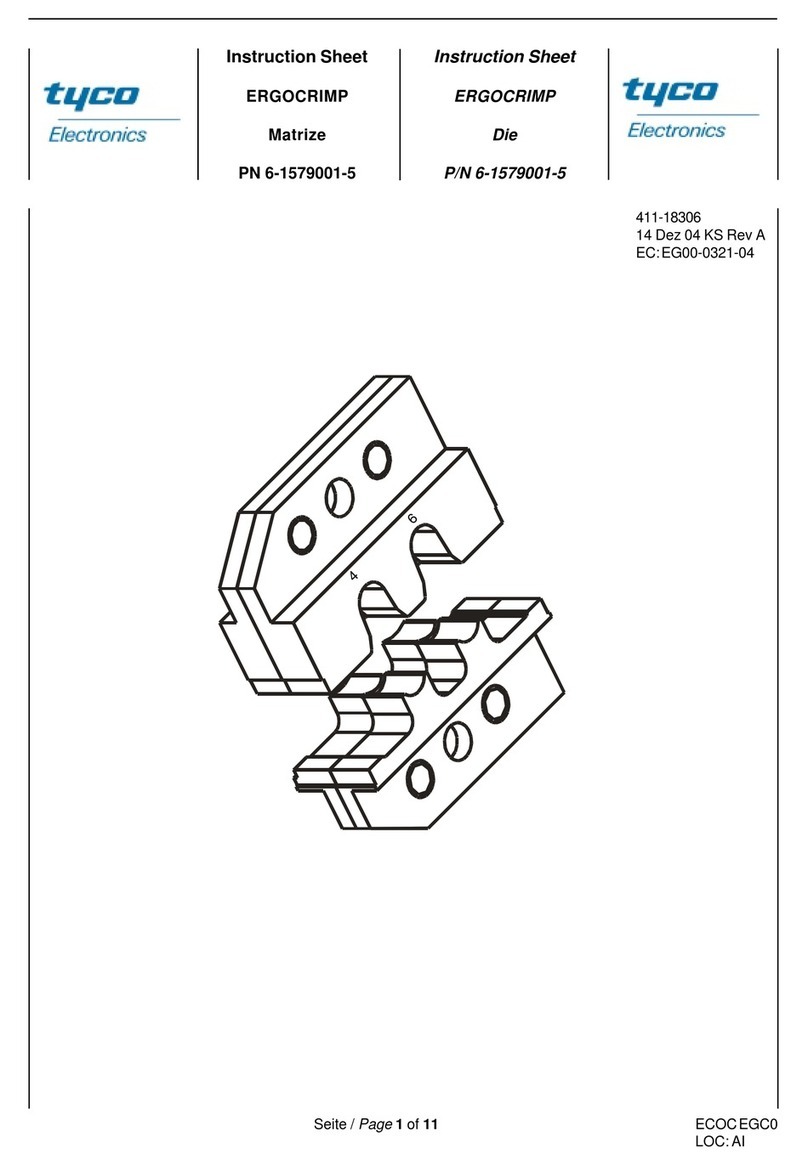

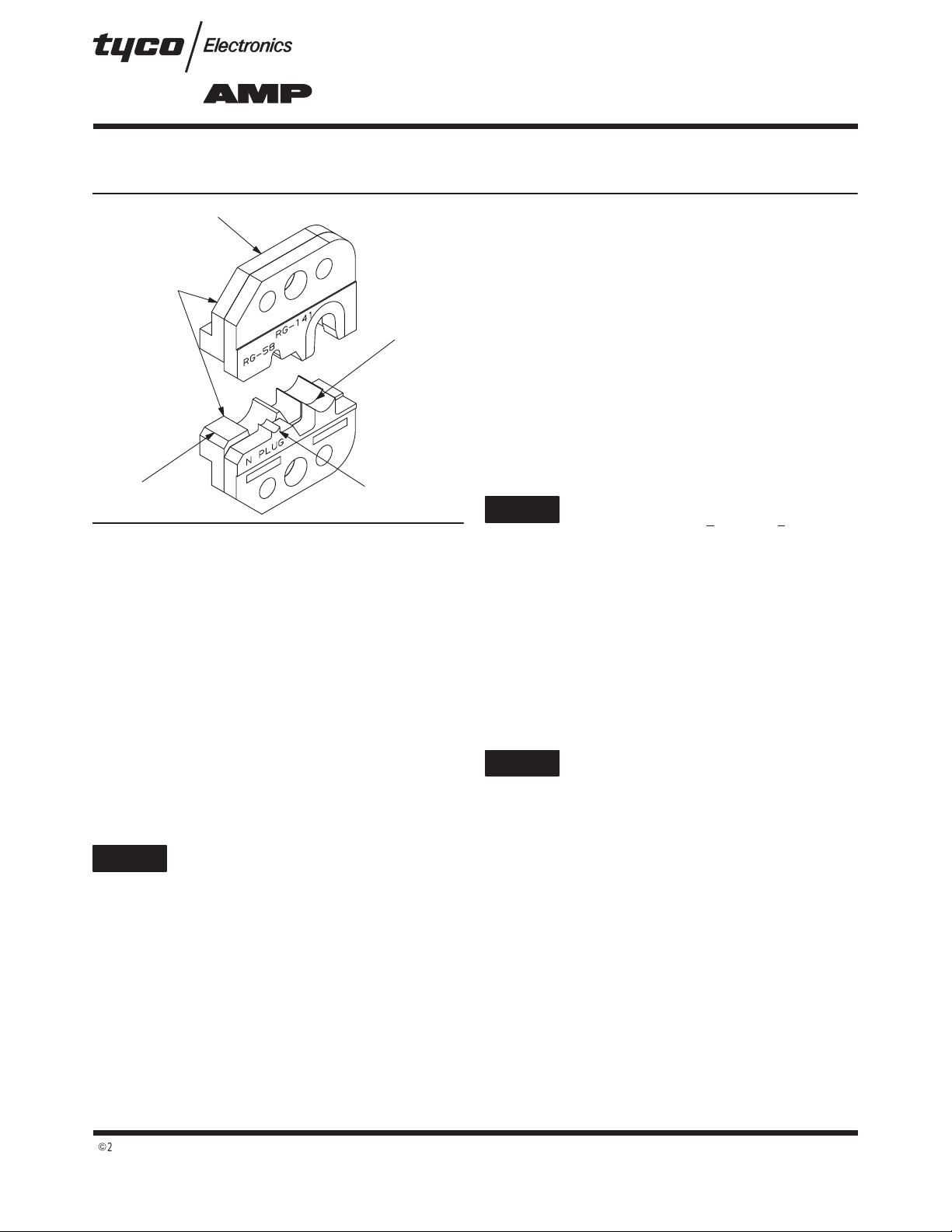

Figure 1

Indenter

Die

Anvil

Die

Ferrule

Crimping

Chambers

CenterContact

Crimping

Chamber

Typical

CrimpingDie

Assembly

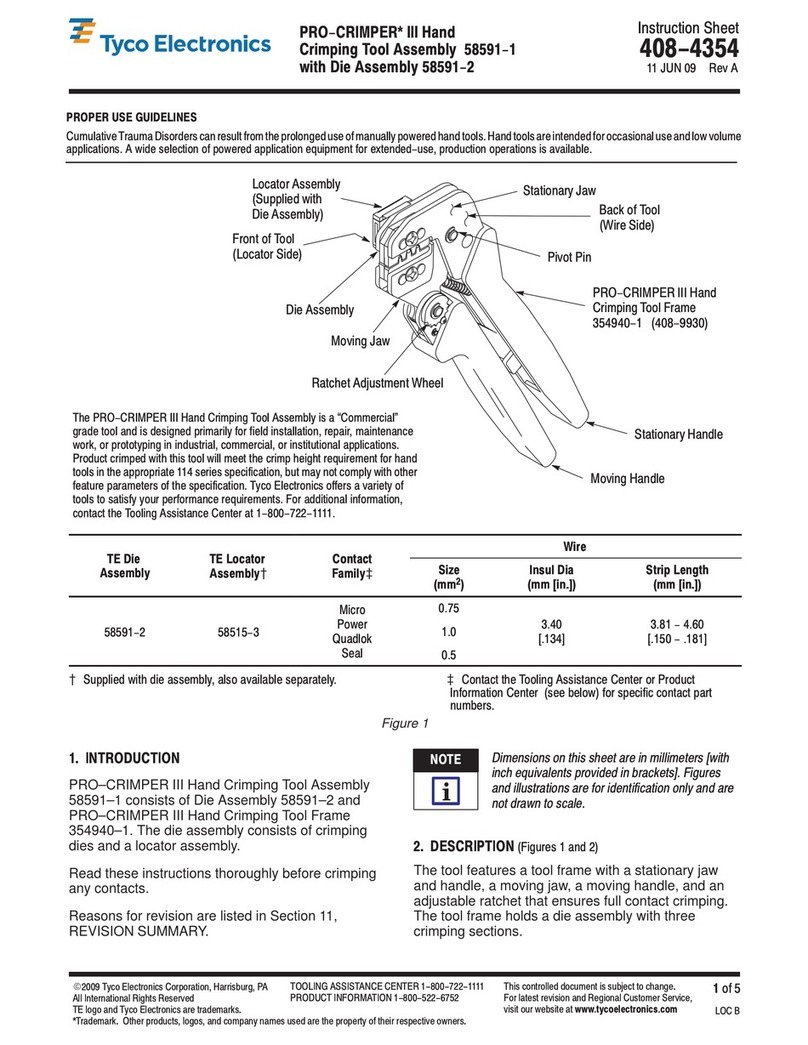

1. INTRODUCTION

SDE (Four–Piece) Crimping Die Assemblies are

designed to crimp a variety of connectors when used

in PRO–CRIMPER* II Frame Assembly 354940–1.

Refer to Figure 5 for a list of connectors and their

associated dies.

Catalog 1307191 provides a guide for cable–

to–connector selection. For connectors not

referenced in the catalog, contact Tyco Electronics

Product Engineering for recommendations.

Refer to instruction sheet 408–9930 for information

concerning PRO–CRIMPER II Hand Tool Frame

354940–1.

Dimensions in this document are in metric units

[with U.S. customary units in brackets]. Figures

are for reference only and are not drawn to scale.

Reasons for revision are provided in Section 9,

REVISION SUMMARY.

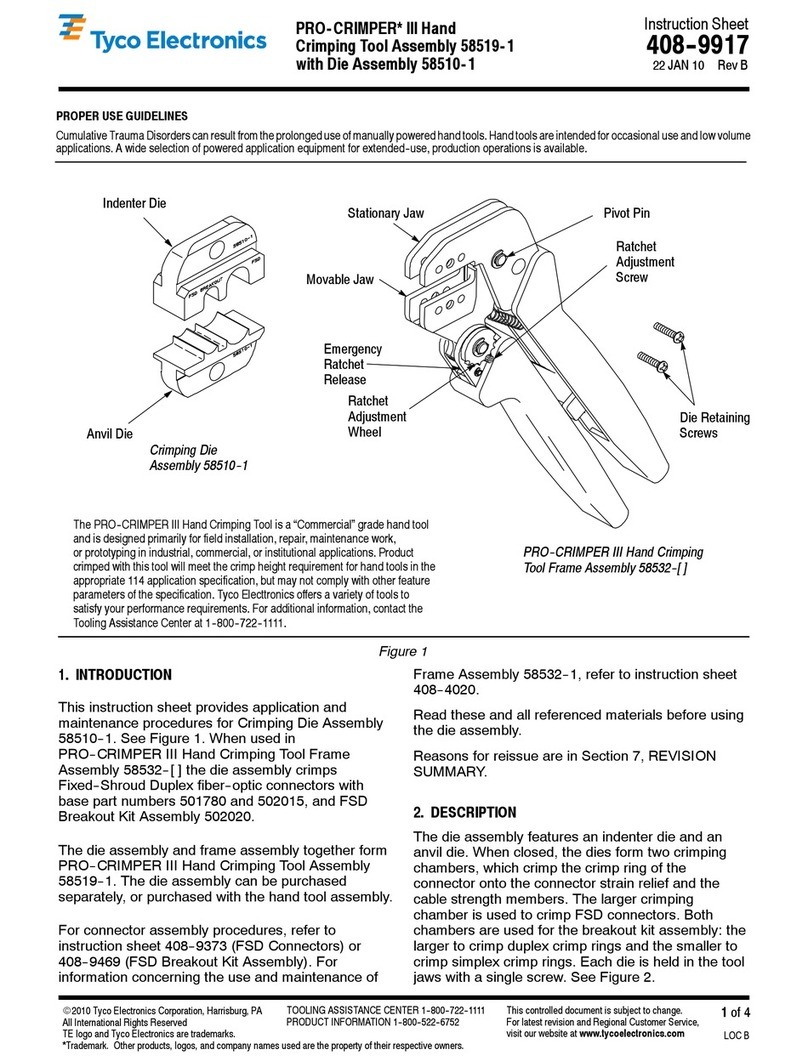

2. DESCRIPTION

Each four–piece crimping die assembly consists of

two indenter dies and two anvil dies, which when

closed form two or three crimping chambers. The

larger crimping chambers crimp the ferrule of the

connector onto the coaxial cable. The smaller

crimping chamber crimps the center contact onto the

center conductor of the coaxial cable. Each die is held

in the PRO–CRIMPER II hand tool jaws by a single

screw.

3. DIE INSTALLATION (Figure 1)

1. Close the tool handles until the ratchet releases,

(hand tool only) then allow the tool handles to open

fully.

2. Install anvil die in the movable jaw of the tool

frame. Align the die with the retaining screw hole,

then secure die with the die–retaining screw. Do

NOT fully tighten.

3. Install indenter die in the stationary jaw of the

tool frame. Slowly close the tool handles, allowing

the dies to align themselves.

Once the anvil has entered the indenter, place

a copper bus bar (1.57 + 0.05 [.062 + .002]

diameter) into the center contact crimping

chamber of the die assembly.

4. Close the tool handles completely.

5. Securely tighten both screws with the

appropriate screwdriver.

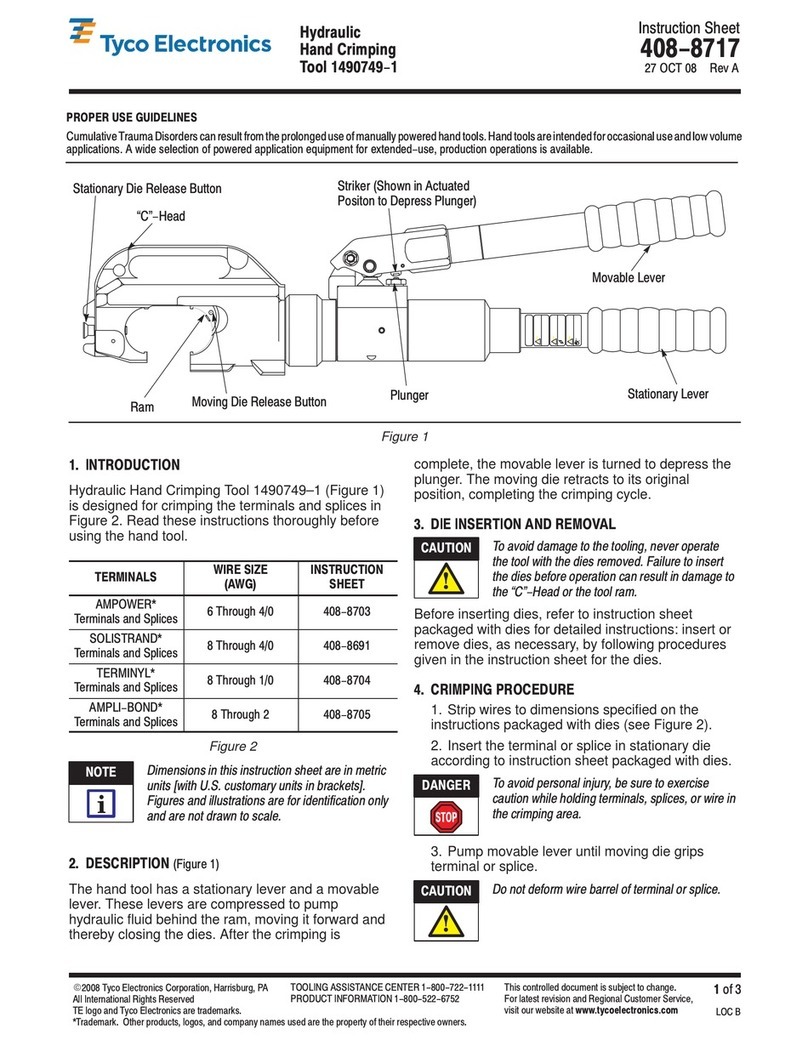

4. CRIMPING PROCEDURE

Select the appropriate cable size and connector. The

wire size and insulation diameter must be within the

specified range for the connector.

This tool is provided with a crimp height

adjustment feature.Initially, the crimp height

should be verified. Refer to Section 5, CRIMP

HEIGHTADJUSTMENT, to verify crimp height

before using the tool.

For detailed information on cable strip lengths and

proper assembly of the connector, refer to the

instructions packaged with the connector. Make sure

that the connector’s ferrule has been placed onto the

cable, and that the cable’s braided shield is flared

away from the cable. Then proceed as follows:

4.1. Crimping the Center Contact (Figure 2)

1. Close the tool handles until the dies are partially

closed.

2. Assemble the center contact onto the cable

center conductor and place the center contact in

the smallest crimping chamber of the anvil die.

Make sure the flange on the end of the center

contact butts against the die.

NOTE

NOTE

NOTE