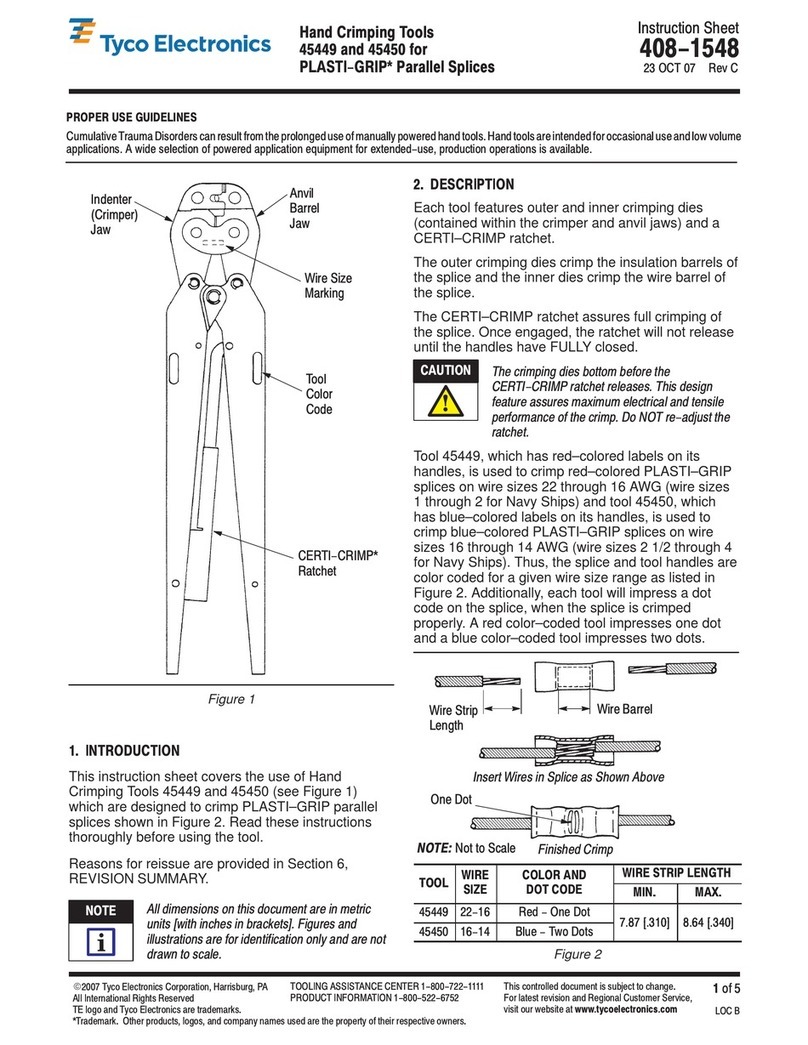

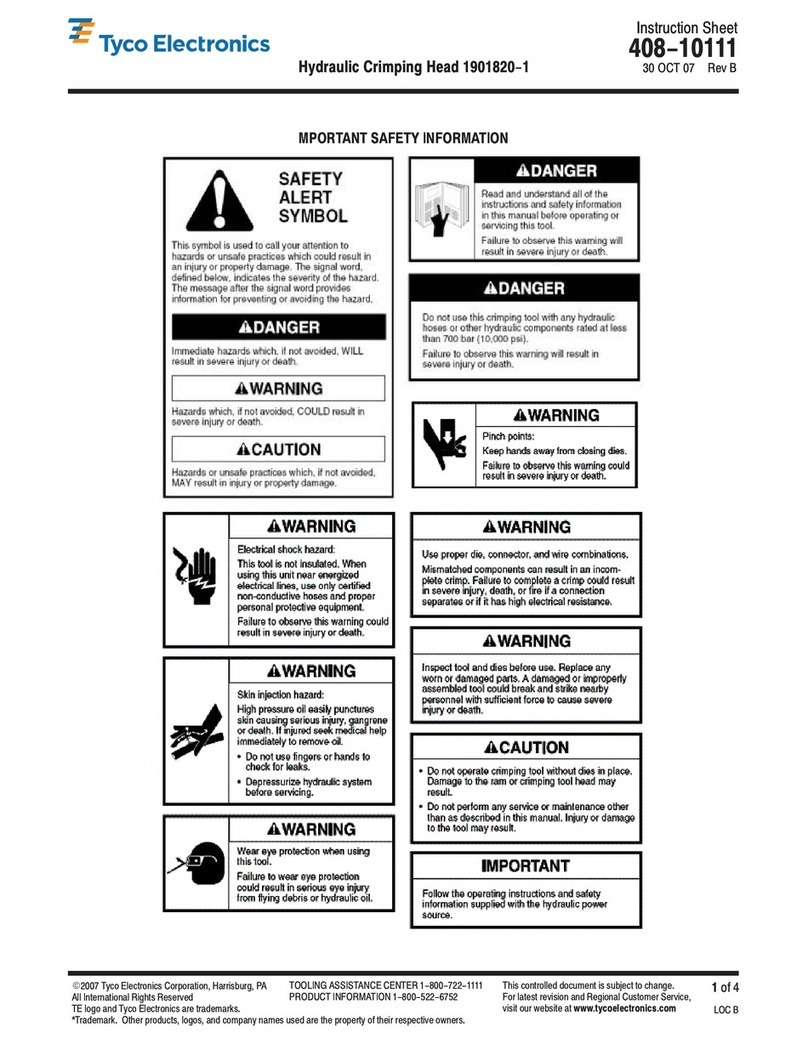

Tyco Electronics SDE PEW-12 User manual

Other Tyco Electronics Crimping Tools manuals

Tyco Electronics

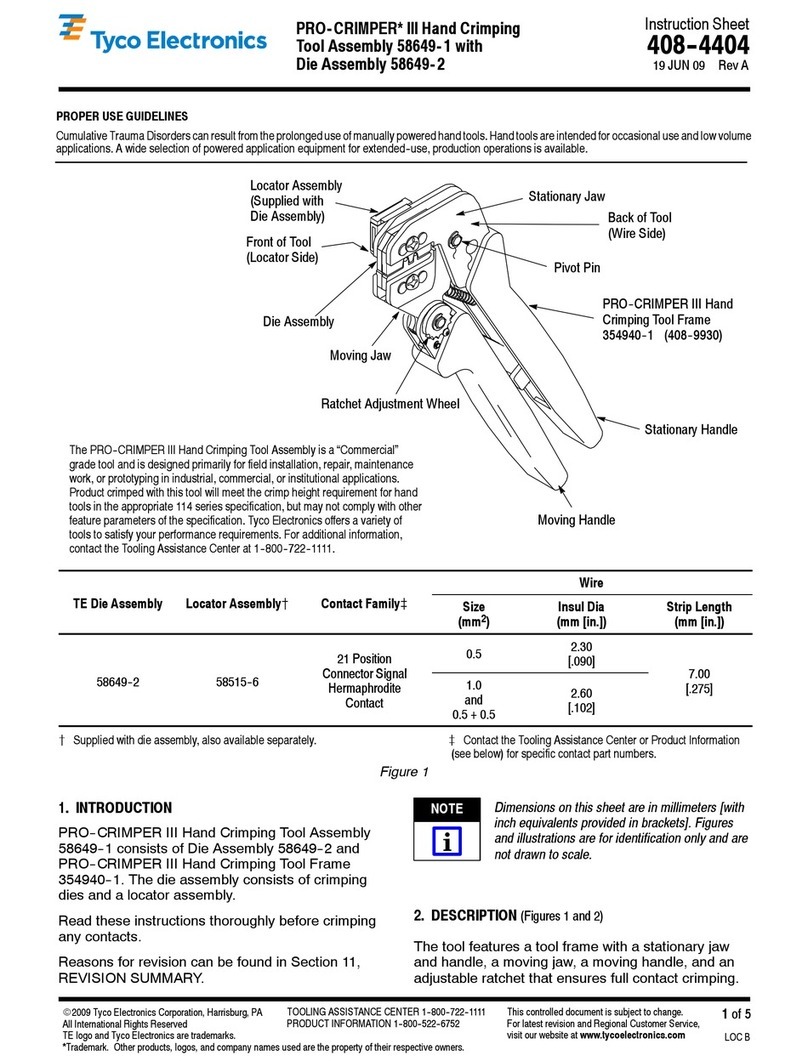

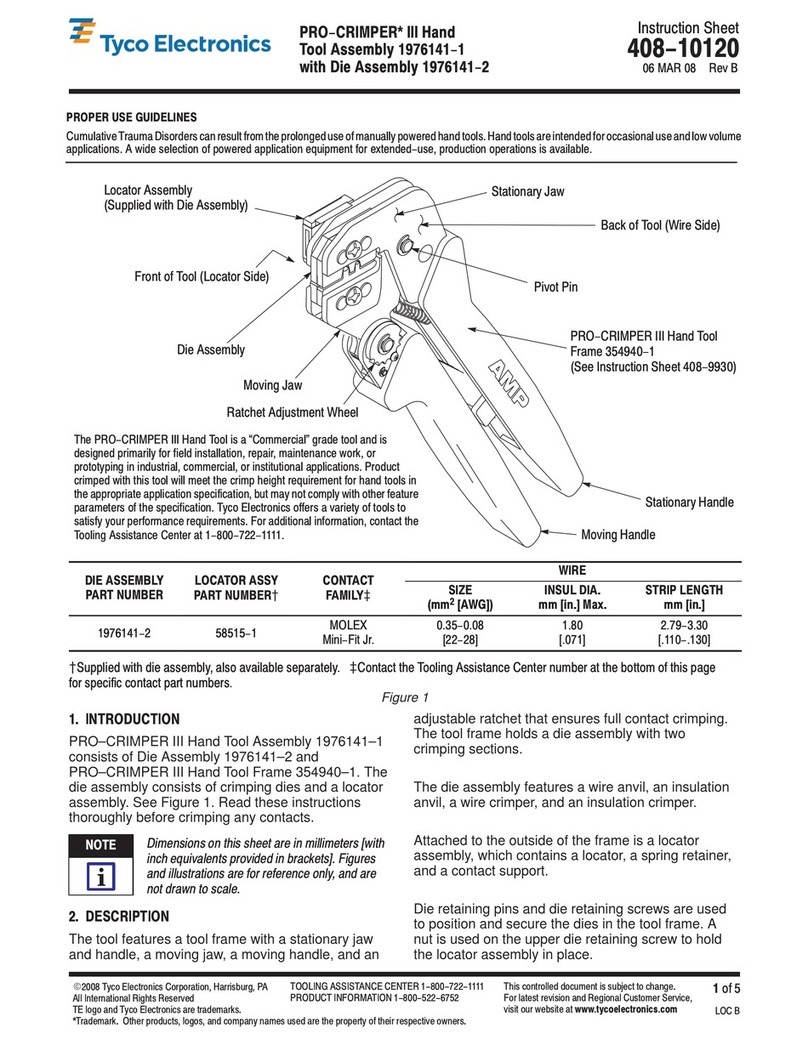

Tyco Electronics PRO-CRIMPER III User manual

Tyco Electronics

Tyco Electronics PRO-CRIMPER III User manual

Tyco Electronics

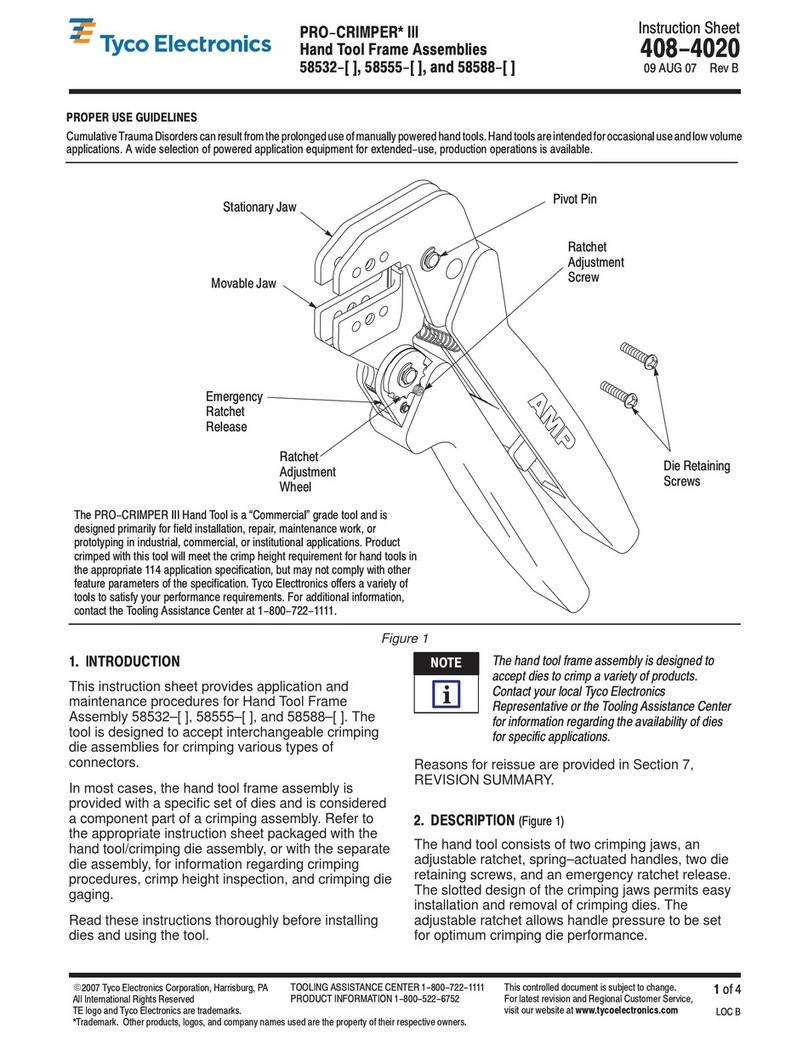

Tyco Electronics 58532 Series User manual

Tyco Electronics

Tyco Electronics PRO- CRIMPER III User manual

Tyco Electronics

Tyco Electronics PRO-CRIMPER III User manual

Tyco Electronics

Tyco Electronics 2-1579004-9 User manual

Tyco Electronics

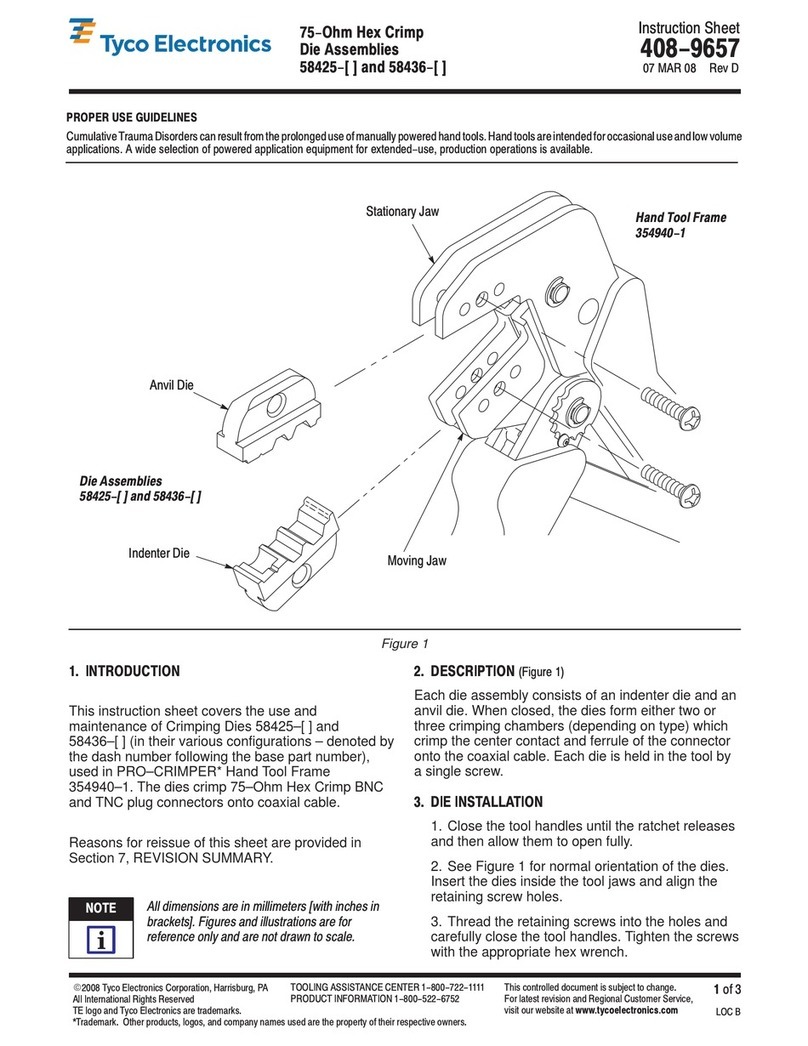

Tyco Electronics 58425 Series User manual

Tyco Electronics

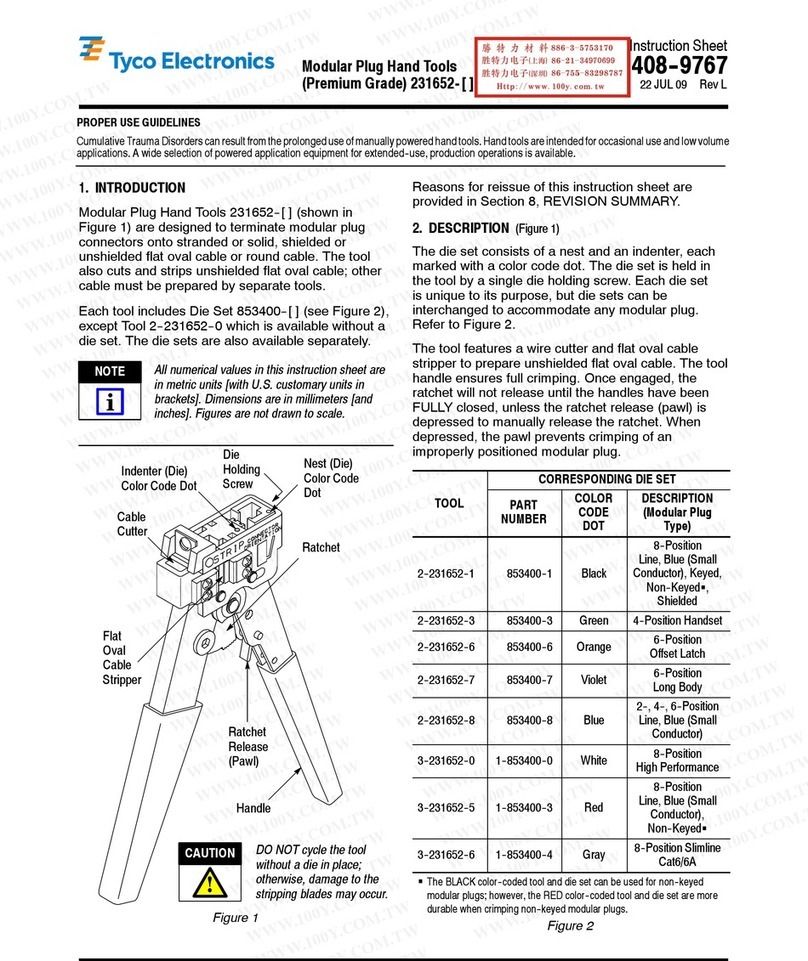

Tyco Electronics 2-231652-1 User manual

Tyco Electronics

Tyco Electronics 58613-1 User manual

Tyco Electronics

Tyco Electronics PRO-CRIMPER III User manual

Tyco Electronics

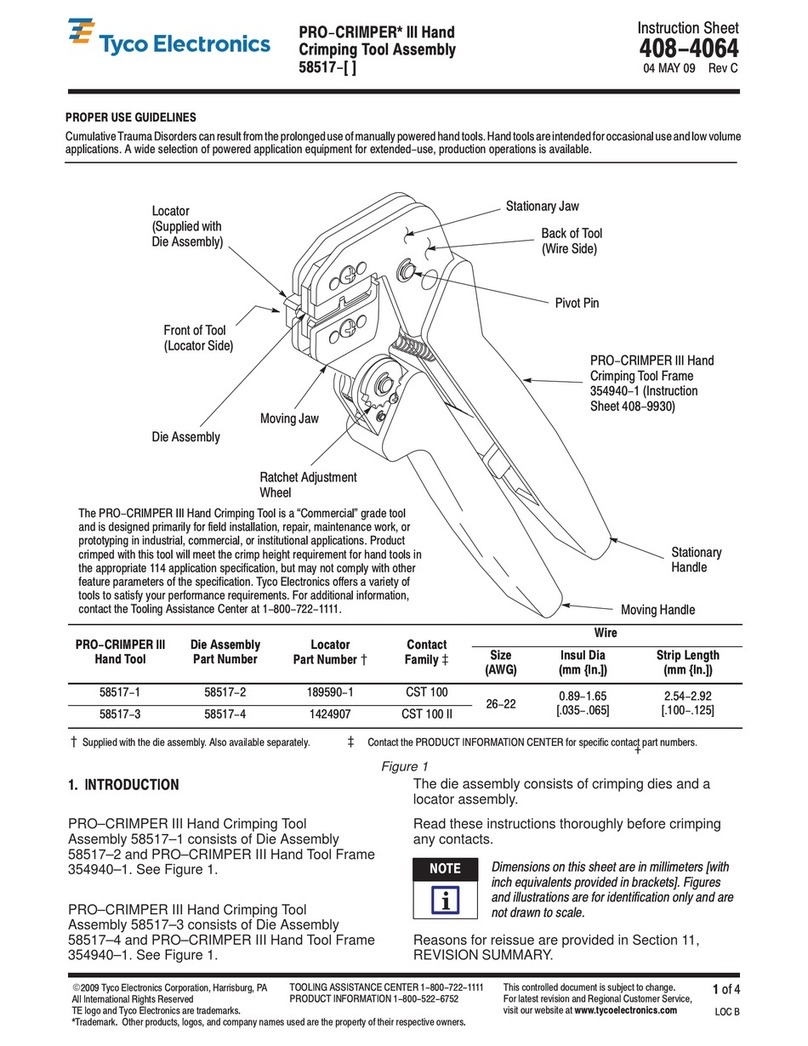

Tyco Electronics PRO-CRIMPER III 58517 Series User manual

Tyco Electronics

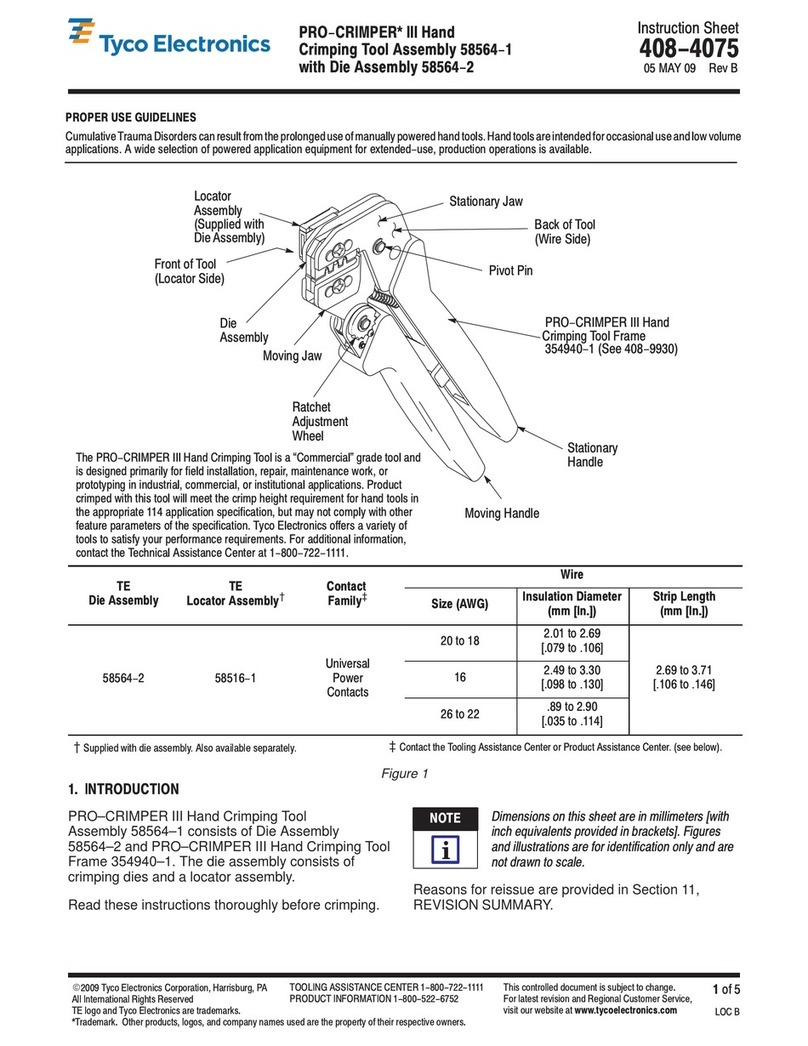

Tyco Electronics PRO-CRIMPER III 58564-1 User manual

Tyco Electronics

Tyco Electronics PRO-CRIMPER III User manual

Tyco Electronics

Tyco Electronics PRO-CRIMPER III User manual

Tyco Electronics

Tyco Electronics PRO-CRIMPER III User manual

Tyco Electronics

Tyco Electronics 90035-3 User manual

Tyco Electronics

Tyco Electronics PRO-CRIMPER III User manual

Tyco Electronics

Tyco Electronics PRO-CRIMPER III User manual

Tyco Electronics

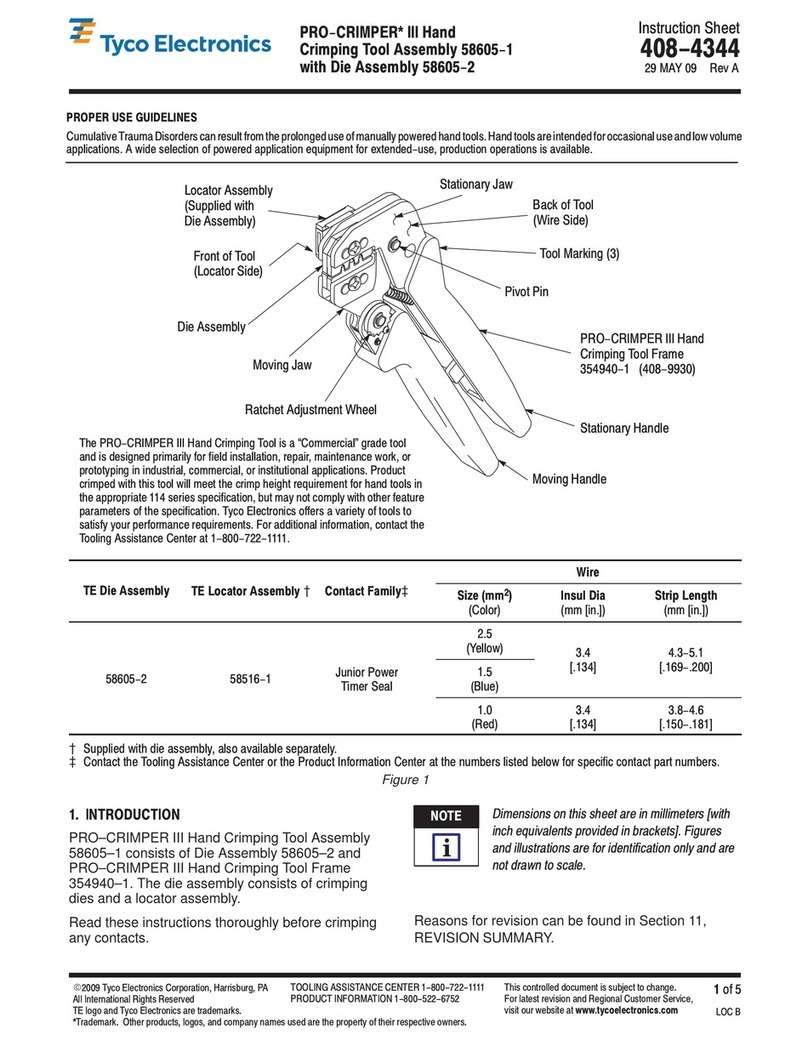

Tyco Electronics 58605-1 User manual

Tyco Electronics

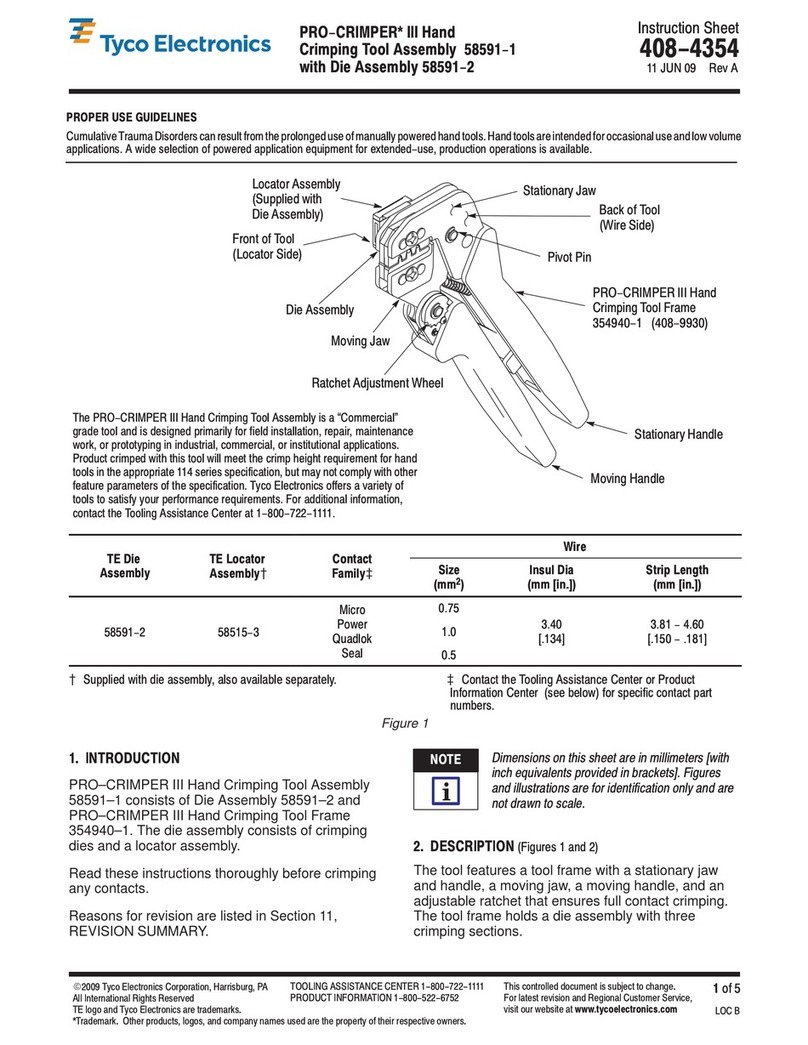

Tyco Electronics 58591-1 User manual

Popular Crimping Tools manuals by other brands

Continental Refrigerator

Continental Refrigerator PC150HD quick start guide

TE Connectivity

TE Connectivity ERGOCRIMP 1-1579001-3 instruction sheet

Emerson

Emerson Klauke ES 105CFB manual

TE Connectivity

TE Connectivity 539 726-2 instruction sheet

molex

molex 207129 Series Specification sheet

TE Connectivity

TE Connectivity 46447 instruction sheet