Tyco Electronics 1901820-1 User manual

Other Tyco Electronics Crimping Tools manuals

Tyco Electronics

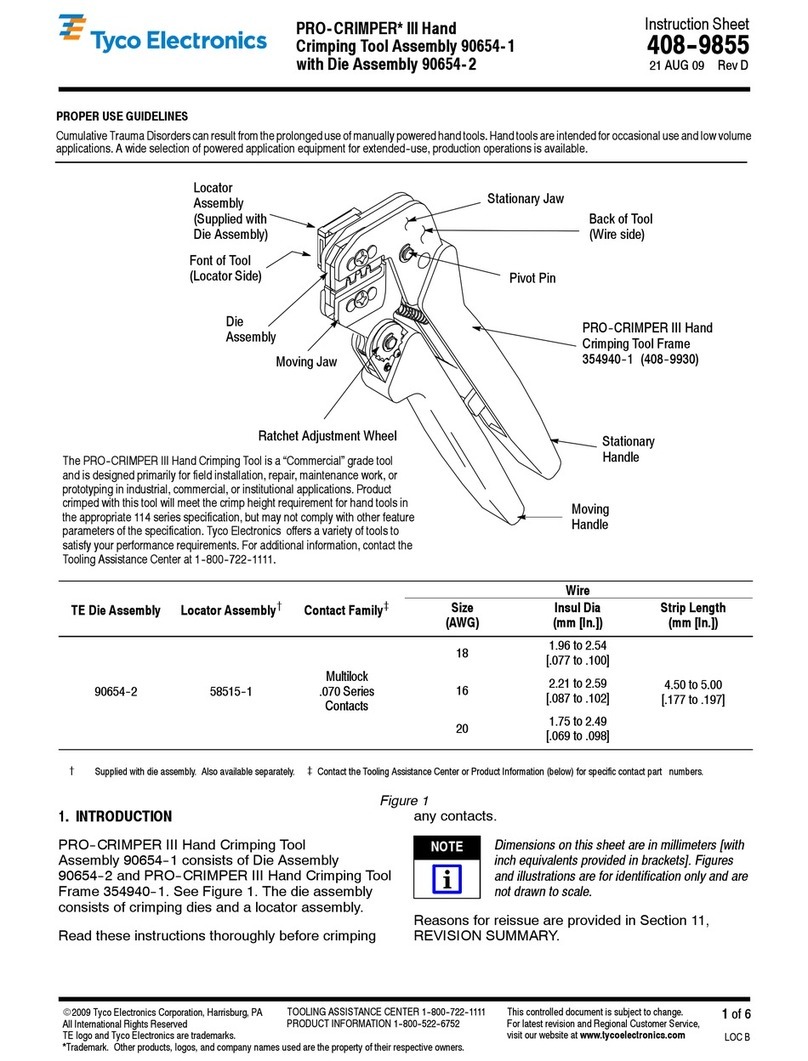

Tyco Electronics PRO-CRIMPER III User manual

Tyco Electronics

Tyco Electronics PRO-CRIMPER III User manual

Tyco Electronics

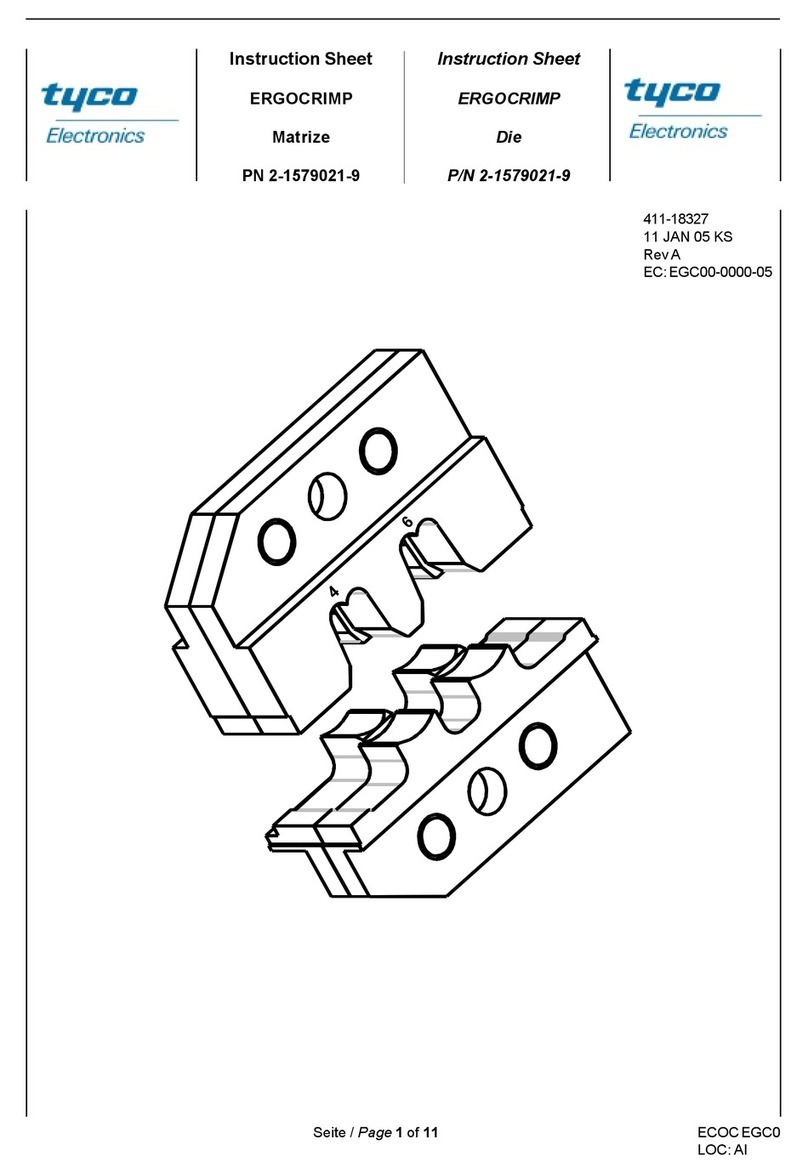

Tyco Electronics ERGOCRIMP 2-1579021-9 User manual

Tyco Electronics

Tyco Electronics CERTI-CRIMP II User manual

Tyco Electronics

Tyco Electronics 46121 User manual

Tyco Electronics

Tyco Electronics 46073 User manual

Tyco Electronics

Tyco Electronics AMP SDE PEW 12 User manual

Tyco Electronics

Tyco Electronics ERGOCRIMP 3-1579001-5 User manual

Tyco Electronics

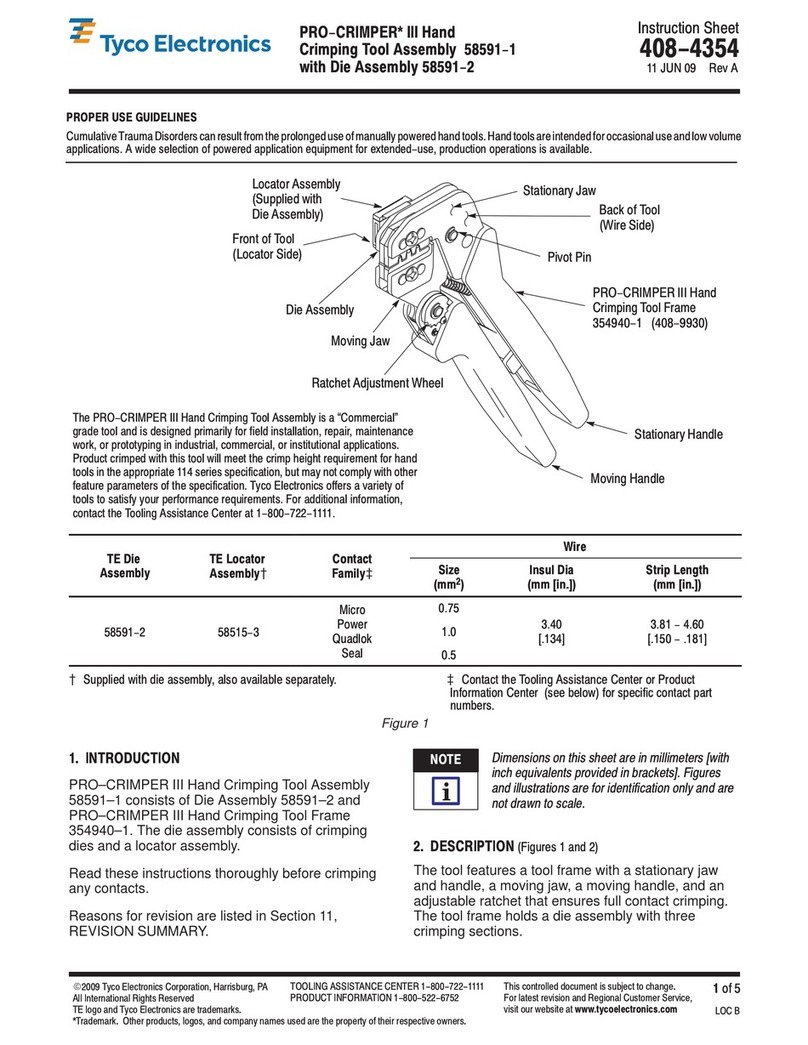

Tyco Electronics 58591-1 User manual

Tyco Electronics

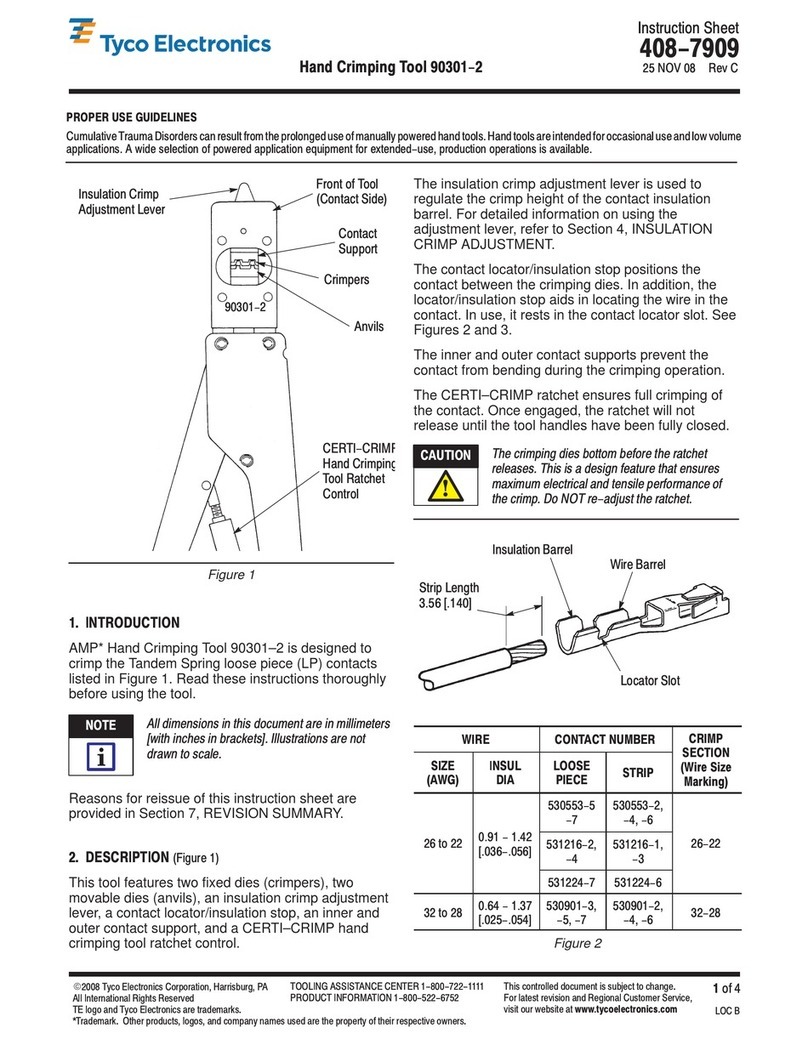

Tyco Electronics 90301-2 User manual

Tyco Electronics

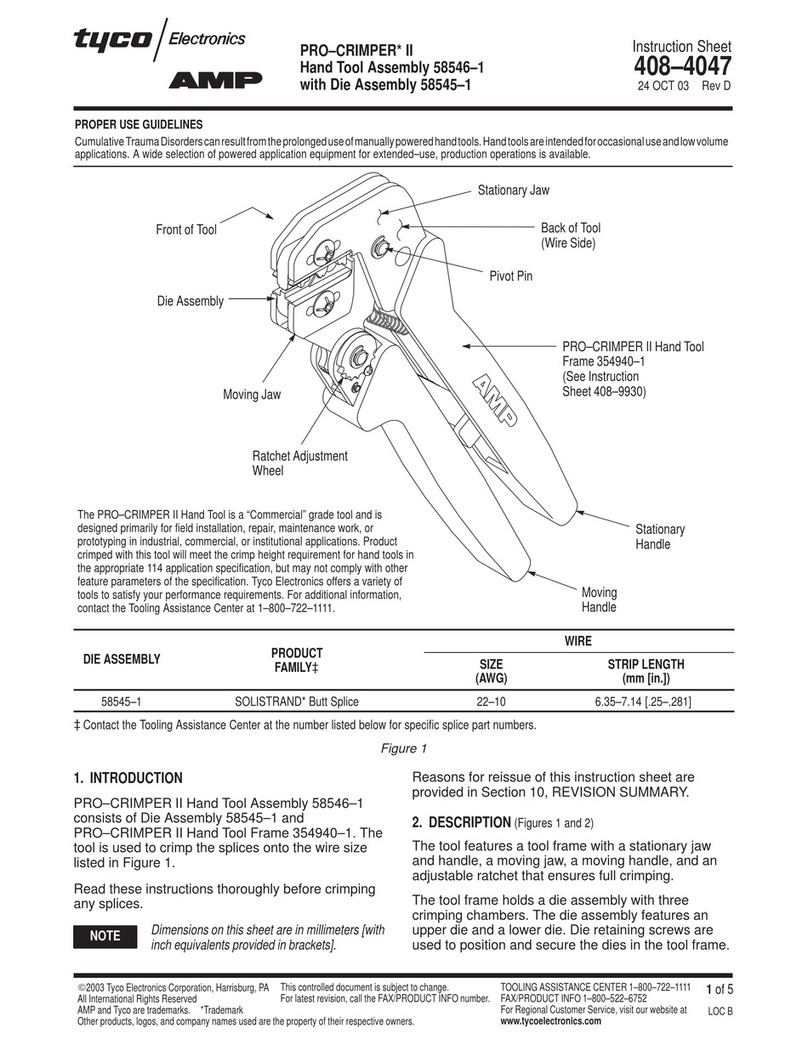

Tyco Electronics PRO-CRIMPER II User manual

Tyco Electronics

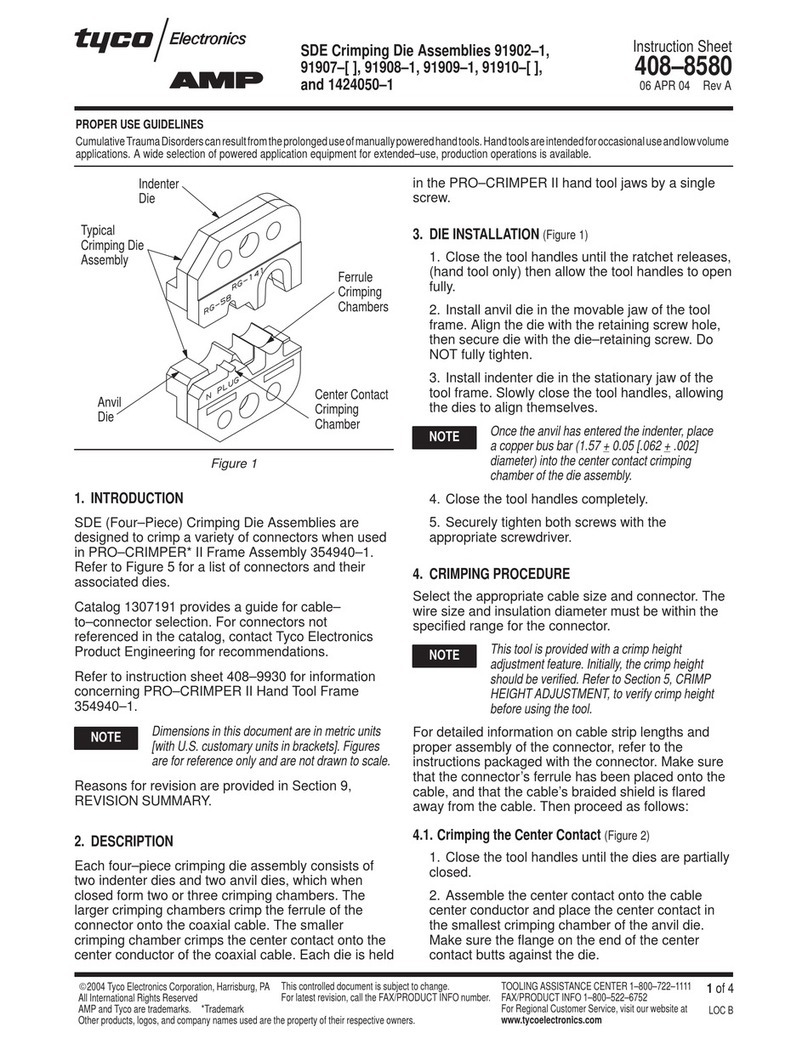

Tyco Electronics AMP 91907 User manual

Tyco Electronics

Tyco Electronics 2-1579004-9 User manual

Tyco Electronics

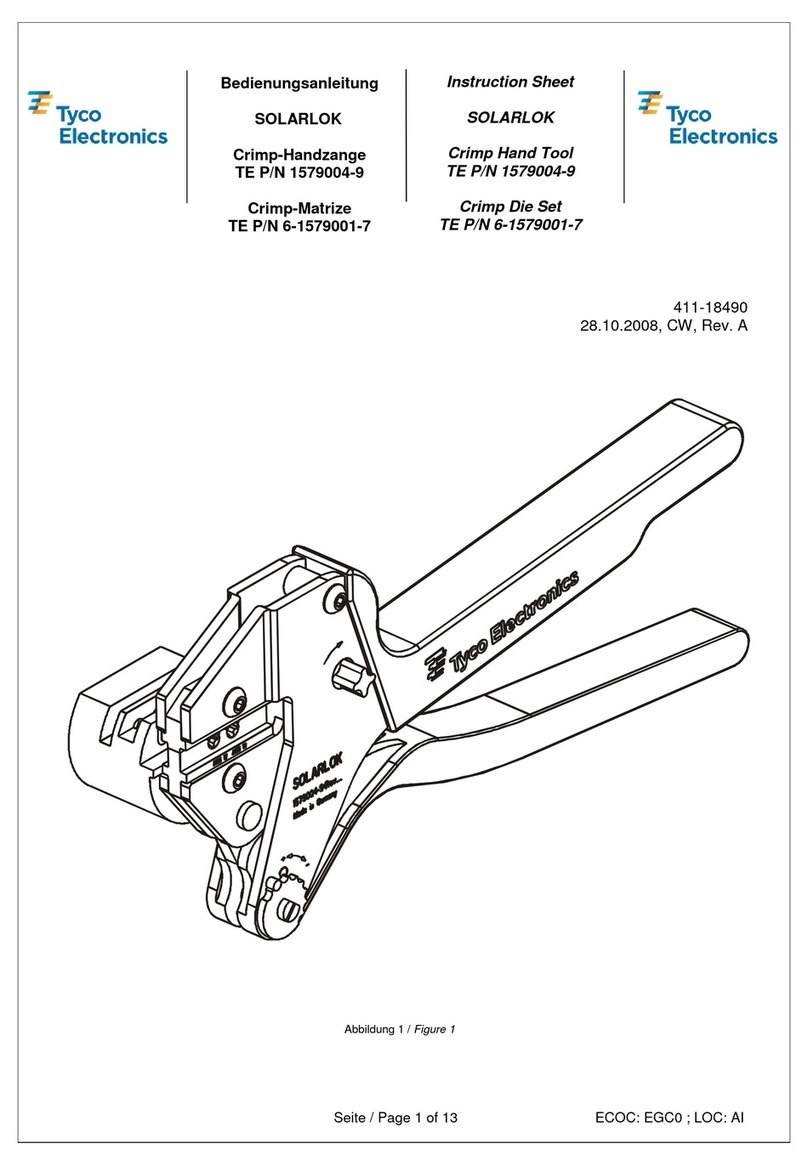

Tyco Electronics SOLARLOK 1579004-9 User manual

Tyco Electronics

Tyco Electronics 1752787-1 User manual

Tyco Electronics

Tyco Electronics 90035-3 User manual

Tyco Electronics

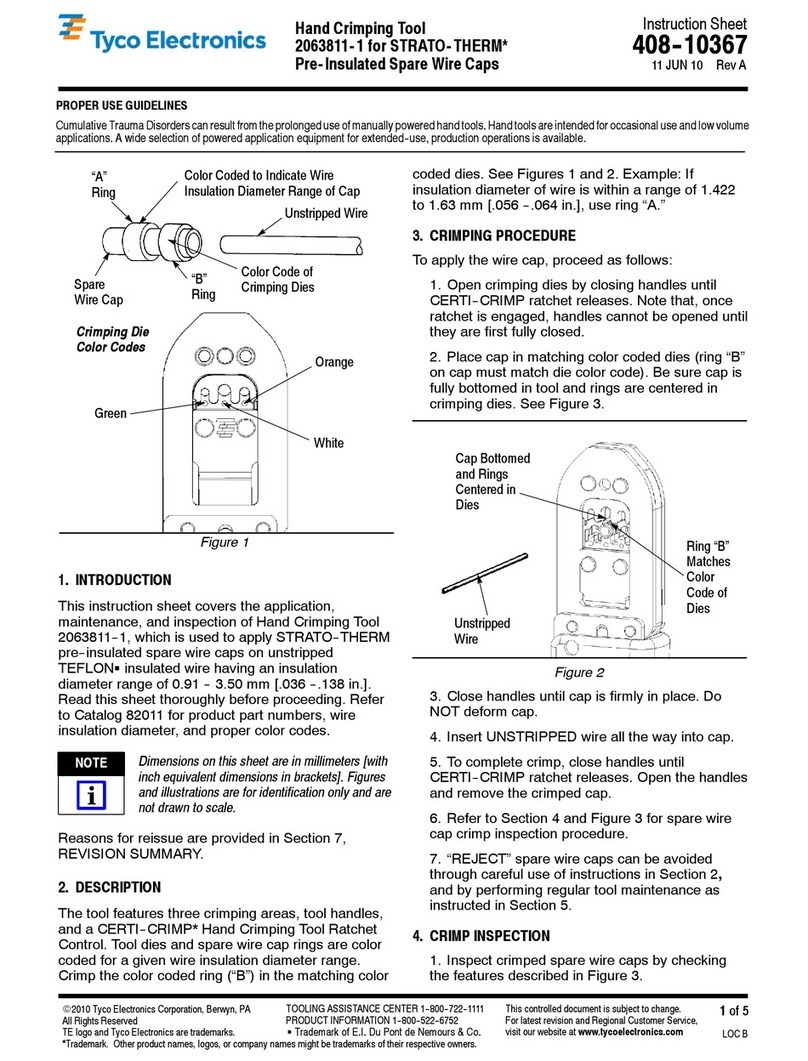

Tyco Electronics 2063811-1 User manual

Tyco Electronics

Tyco Electronics PRO-CRIMPER III User manual

Tyco Electronics

Tyco Electronics PRO-CRIMPER III User manual

Tyco Electronics

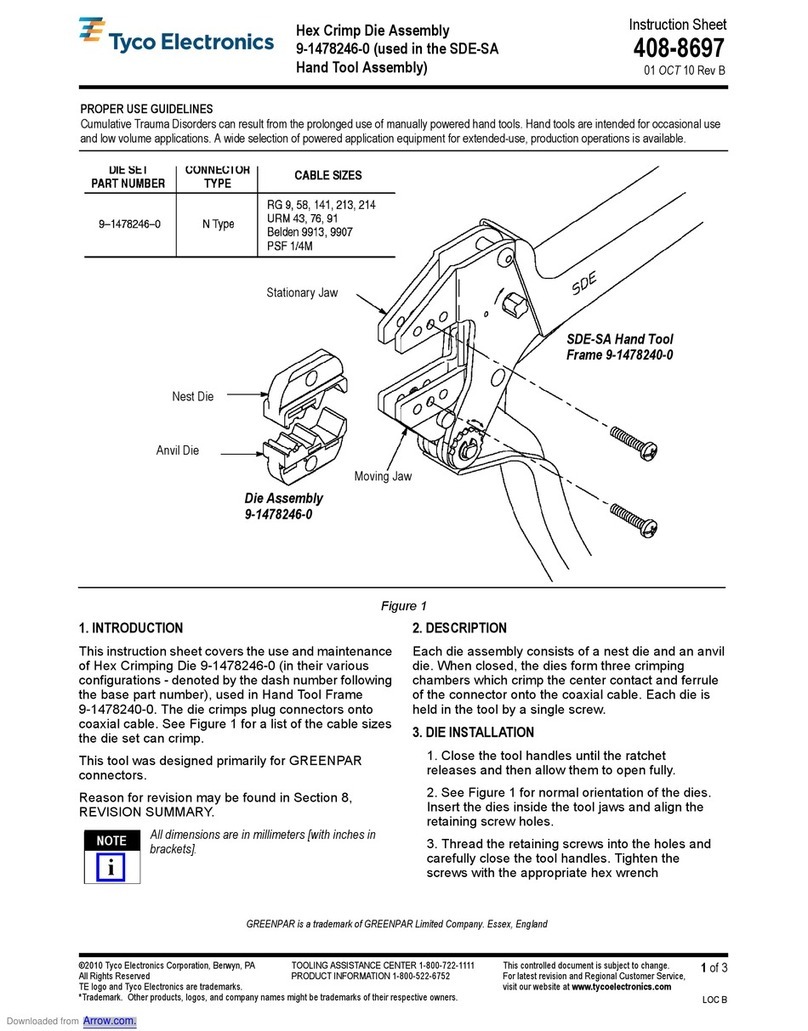

Tyco Electronics 9-1478246-0 User manual

Popular Crimping Tools manuals by other brands

Continental Refrigerator

Continental Refrigerator PC150HD quick start guide

TE Connectivity

TE Connectivity ERGOCRIMP 1-1579001-3 instruction sheet

Emerson

Emerson Klauke ES 105CFB manual

TE Connectivity

TE Connectivity 539 726-2 instruction sheet

molex

molex 207129 Series Specification sheet

TE Connectivity

TE Connectivity 46447 instruction sheet