3

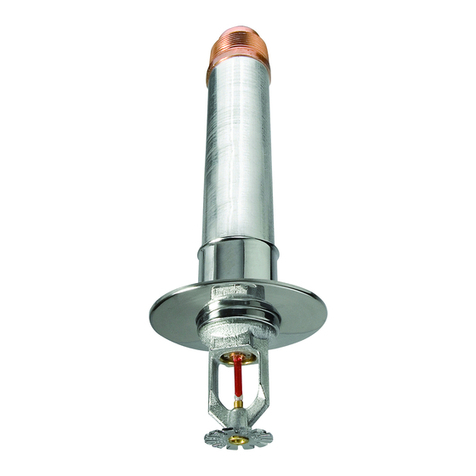

Step 4. Hand tighten the sprinkler

into the fitting. Use an Omega HEC

sprinkler wrench to tighten the

assembly into the fitting. A leak tight

joint requires the application of only

7-14 ft.-lbs.

(9.5 to 19.0 Nm)

of torque.

A tangential force of 14-28 lbs.

(62.3

to 124.5 N)

delivered through a 6"

(150

mm)

long rachet handle will deliver

adequate torque. Torque levels over

21 ft.-lbs

(28.6 Nm)

may distort the

orifice seal, resulting in leakage.

Step 5. To install the escutcheon

plate, align it with and press it over

the sprinkler body until the outer edge

of the escutcheon meets the

mounting surface.

Do not over or under tighten the

sprinkler to compensate for

inaccurate escutcheon plate

adjustment.

Caution: Special care must be

taken when installing with a CPVC

system. Sprinklers must be installed

after the CPVC manufacturer's

recommended setting time for the

primer and cement to ensure that

neither accumulate within the

sprinkler.

Special care must be taken when

installing with a copper system.

Sprinklers must be installed only after

the inside of the sprinkler nipple and

associated fittings have been wire

brushed to remove any flux. Residual

flux can cause corrosion and in

extreme cases can impair proper

sprinkler operation.

Installation In the event of a thread leak,

remove the unit, apply new pipe joint

compound or tape, and reinstall.

Installation Sequence

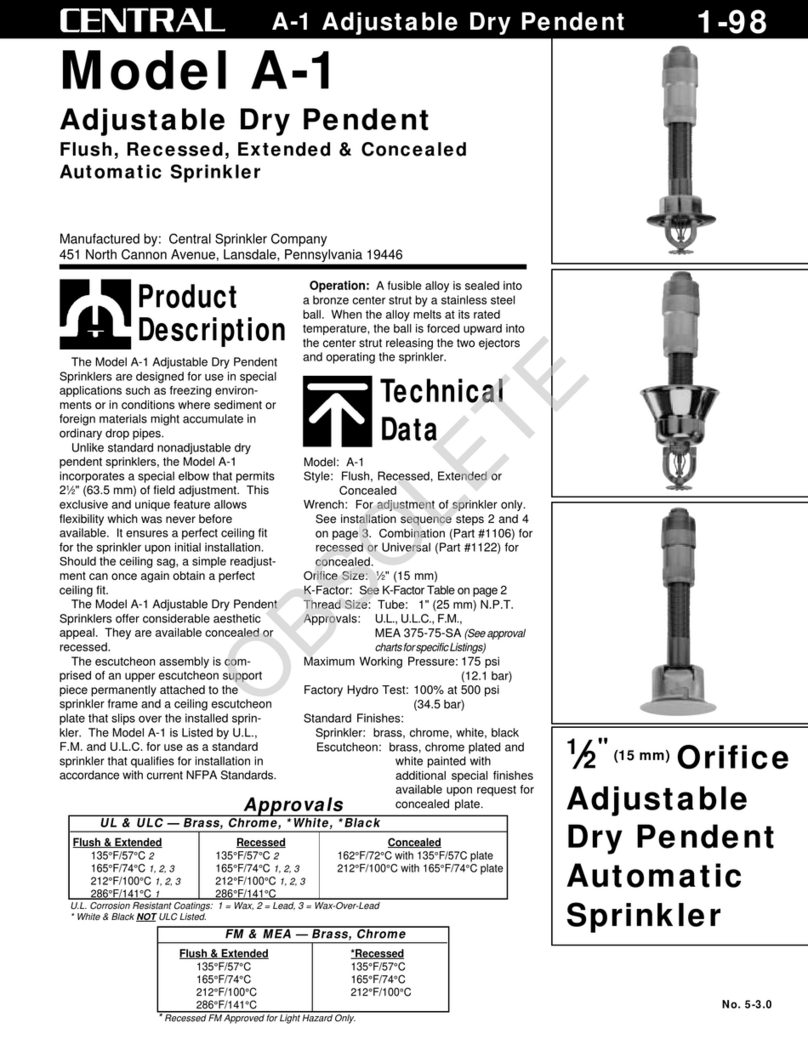

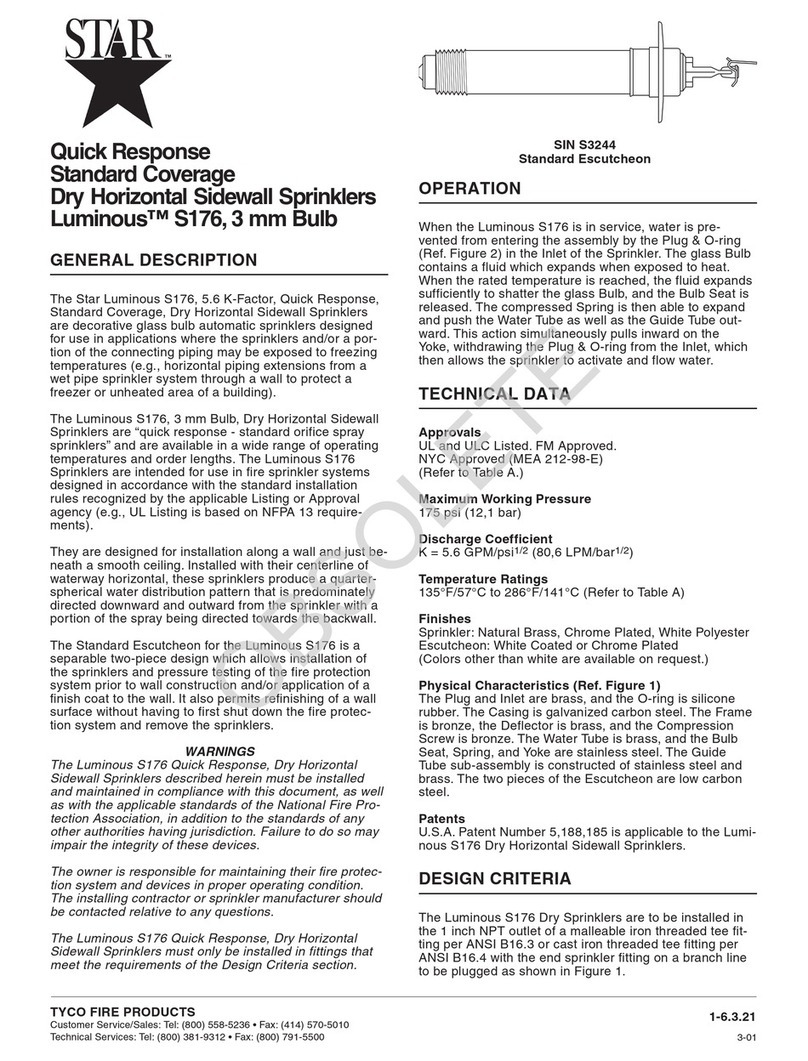

Step 1. The unit must be installed in

the horizontal position.

Step 2. The face of the sprinkler

fitting should be installed 5/8"±1/8"

(15.9 mm

±

3.2 mm

) behind the finished

wall line. Adjustments are made via

the adjustable sliding escutcheon

plate to compensate for variations in

the fittings.

Do not use the escutcheon plate to

hold the unit in position. The

sprinkler will function properly, only

when the system piping is anchored

to the building structure. Otherwise,

reaction forces from system initiation

could alter the sprinkler alignment

and disrupt the distribution pattern.

Step 3. Use only a non-hardening

pipe joint compound or Teflon* tape.

Apply to the male threads only.

Model HEC-12EC Sprinklers must

be installed in accordance with

current NFPA 13 Standards.

Deviations from these requirements

and standards or any alteration to the

sprinkler itself will void any warranty

made by Central Sprinkler Company.

In addition, installation must also

meet local government provisions,

codes, and standards as applicable.

The system piping must be properly

sized to insure the minimum required

flow rate from the sprinkler.

Prior to installation, check for

proper model, style, orifice size, and

temperature rating. Install sprinklers

after the piping is in place to avoid

mechanical damage; replace any

damaged unit. Wet pipe systems

must be protected from freezing.

Upon completion of the installation,

the system must be tested per

recognized standards.

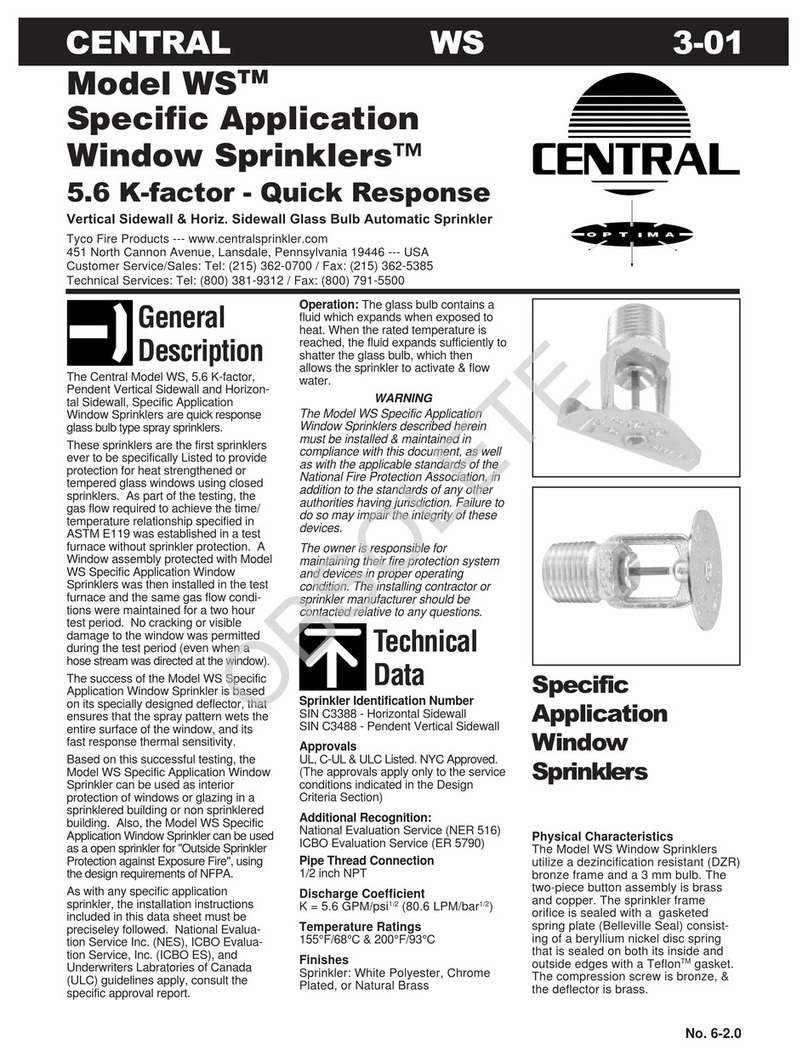

Design

Data

Coverage Area Minimum "A"

Width Throw Flow Deflector Distance Temperature

(pressure) Below Ceiling Rating

16' x 16' 26 gpm (21.6 psi) 4" - 12" 145oF/63oC;160oF/71oC

(4.9m) (4.9m) 98.5 Lpm (1.5 bar) (101.6 - 304.8 mm)

16' x 18' 29 gpm (26.8 psi) 4" - 6" 145oF/63oC

(4.9m) (5.5m) 109.9 Lpm (1.8 bar) (101.6 - 152.4 mm)

16' x 18' 30 gpm (28.7 psi) 4" - 12" 145oF/63oC

(4.9m) (5.5m) 113.7 Lpm (2.0 bar) (101.6 - 304.8 mm)

Care &

Maintenance

Sprinklers must be handled

carefully. They must not be

transported or stored where ambient

temperatures may exceed 100°F/

38°C. For best results, store them in

a cool, dry location in the original

shipping package.

Do not install sprinklers that have

been dropped or visibly damaged.

Sprinklers must never be painted,

coated, plated, or altered in any other

way from manufactured condition or

they may not function properly. Any

* Teflon is a trademark of the DuPont Corp.

Design Requirements — Extended Coverage Quick Response Applications

In Extended Coverage Quick Response Applications, the Model HEC-12EC Sprinklers

are listed for installation in light hazard occupancies only.

Coverage Area Minimum "A"

Width Throw Flow Deflector Distance Temperature

(pressure) Below Ceiling Rating

16' x 16' 29 gpm (26.8 psi) 4" - 6" 160oF/71oC

(4.9m) (4.9m) 109.9 Lpm (1.8 bar) (101.6 - 152.4 mm)

16' x 18' 30 gpm (28.7 psi) 4" - 12" 160oF/71oC

(4.9m) (5.5m) 113.7 Lpm (2.0 bar) (101.6 - 304.8 mm)

16' x 20' 32 gpm (32.7 psi) 4" - 6" 160oF/71oC

(4.9m) (6.1m) 121.3 Lpm (2.3 bar) (101.6 - 152.4 mm)

Design Requirements — Extended Coverage Applications

In Extended Coverage Applications, the Model HEC-12EC Sprinklers are listed for

installation in light hazard occupancies only.