is recommended that the end user be

consulted with respect to the suitability

of these corrosion resistant coatings

for any given corrosive environment.

The effects of ambient temperature,

concentration of chemicals, and

gas/chemical velocity, should be con-

sidered, as a minimum, along with the

corrosive nature of the chemical to

which the sprinklers will be exposed.

APPROVALS AND STANDARDS

Laboratory listings and approvals for

the 11.2 K-Factor, Model F892QR De-

signer, Quick Response, Standard

Coverage, Pendent and Upright Sprin-

klers are given in Table A.

WARNING

The 11.2 K-Factor, Model F892QR

Pendent and Upright Sprinklers de-

scribed herein must be installed and

maintained in compliance with this

document, as well as with the appli-

cable standards of the National Fire

Protection Association, in addition to

the standards of any other authorities

having jurisdiction. Failure to do so

may impair the integrity of these de-

vices.

The owner is responsible for main-

taining their fire protection system

and devices in proper operating con-

dition. The installing contractor or

manufacturer should be contacted

relative to any questions.

Installation of Model F892QR Pen-

dent Sprinklers in recessed escutch-

eons will void all sprinkler warran-

ties, as well as possibly void the

sprinklers Approvals and/or List-

ings.

TECHNICAL DATA

The 11.2 K-Factor, Model F892QR De-

signer, Quick Response, Standard

Coverage, Pendent and Upright

Sprinklers are rated for use at a maxi-

mum service pressure of 175 psi (12,1

bar). They are available in the tem-

perature ratings and finishes indicated

in Table A.

The nominal flow “Q” in GPM (LPM) is

determined by the following formula:

where the nominal sprinkler discharge

coefficient “K” = 11.2 (161,3) and “p”

equals the residual flowing pressure in

psi (bar).

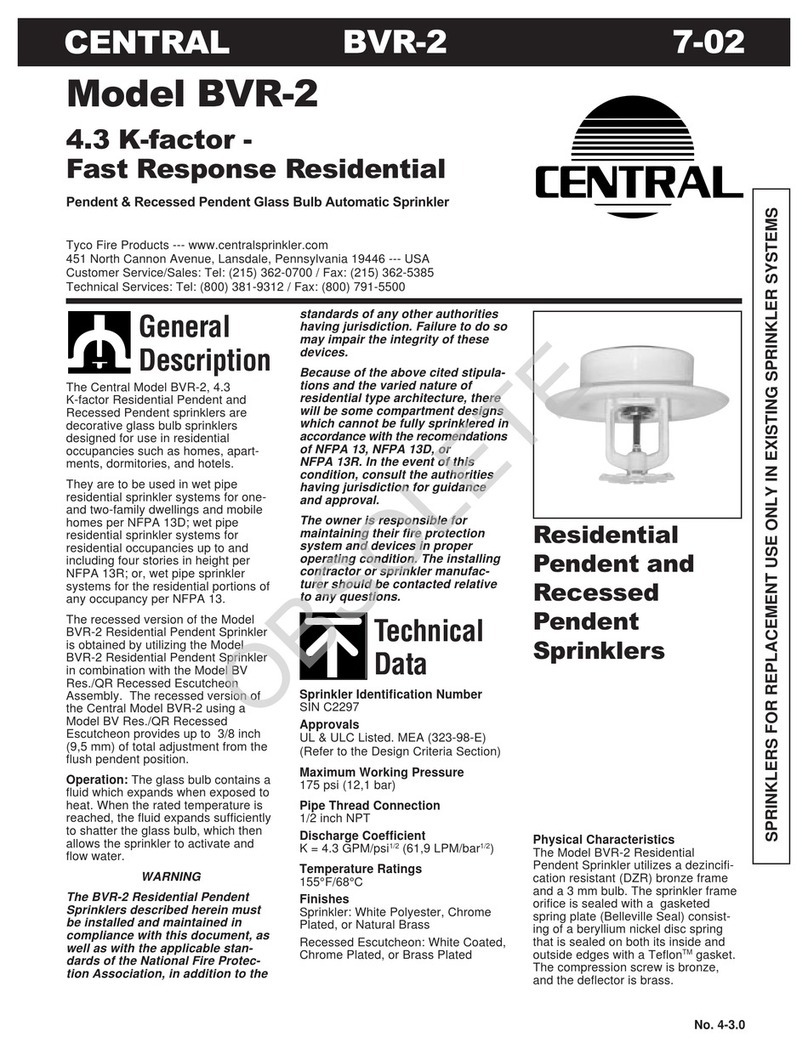

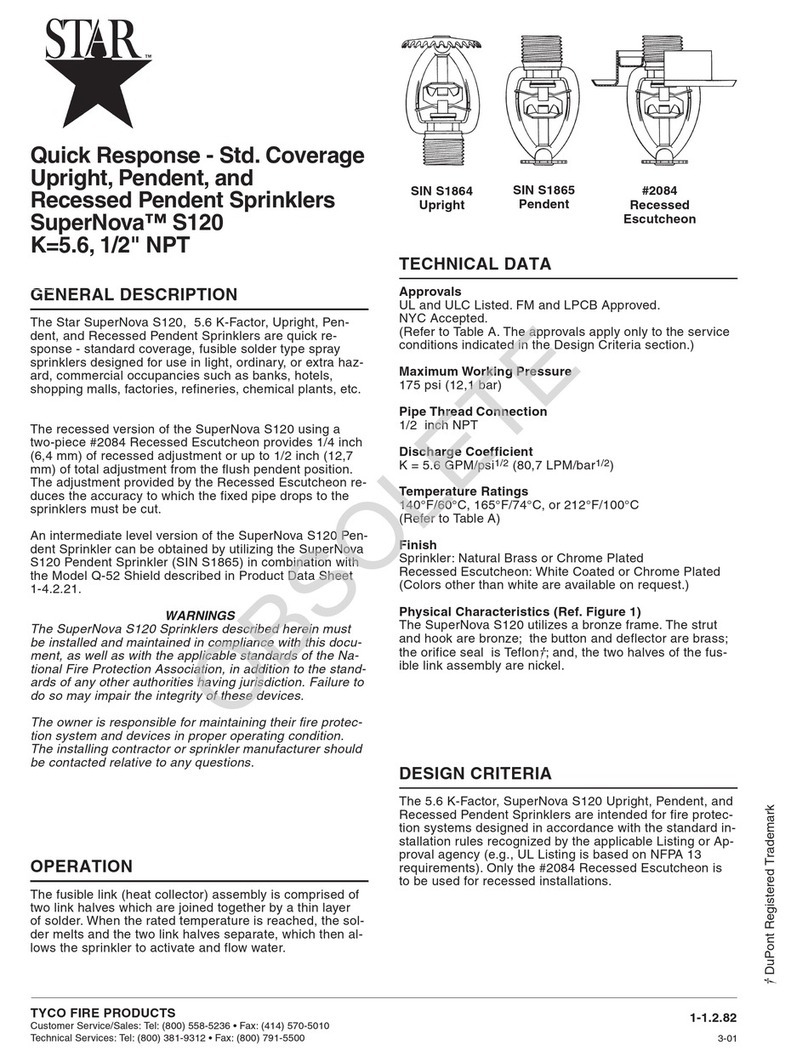

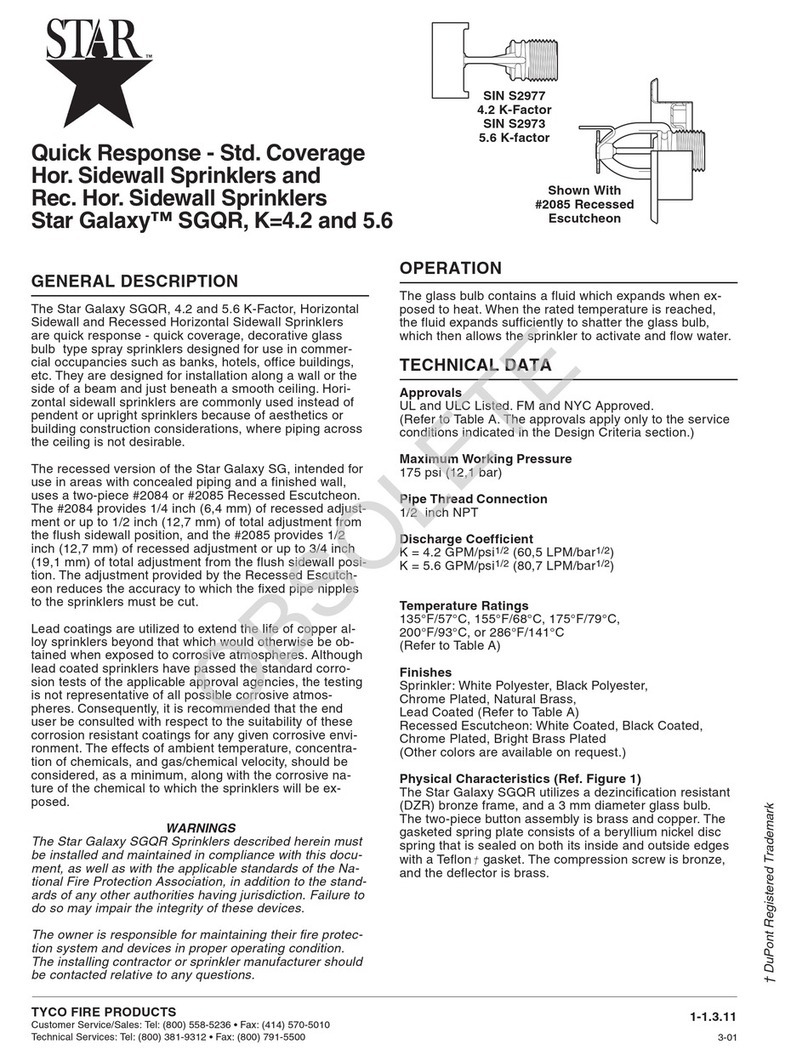

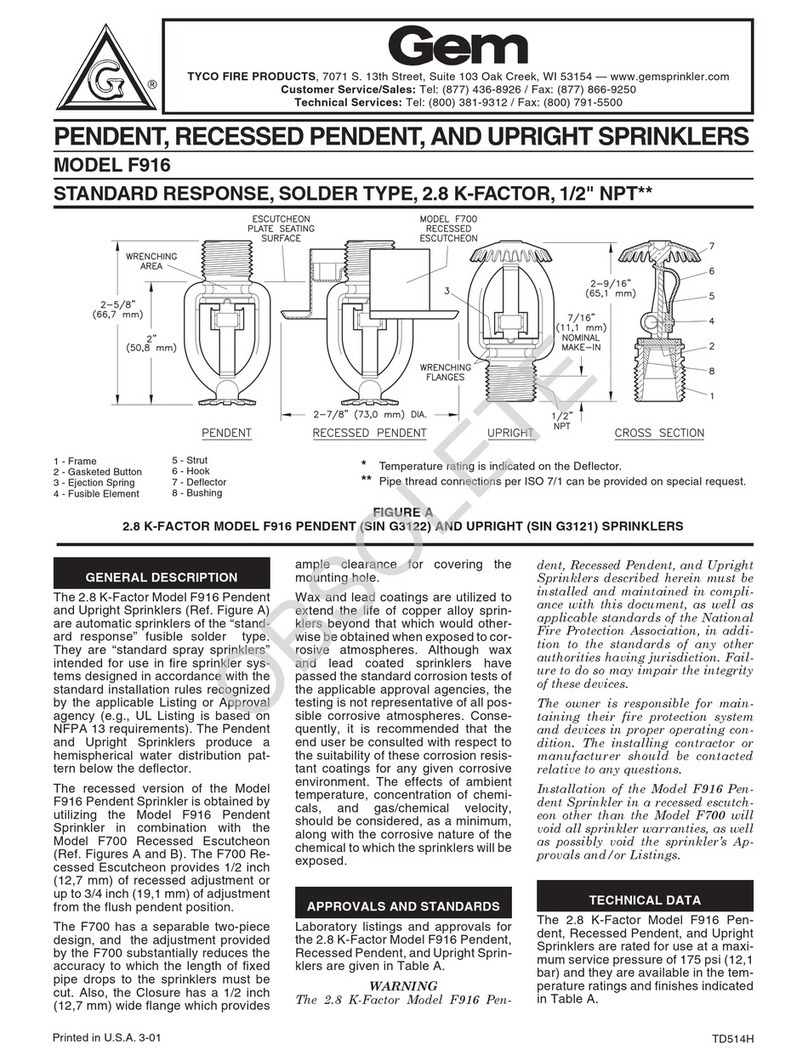

The Frame of the Model F892QR

Sprinklers, (Ref. Figure A), is a dezin-

cification resistant bronze. The Button

is bronze, and the Gasketed Spring

Plate is sealed on both its inside and

outside faces with a Teflon

gasket.

The Compression Screw and the De-

flector are brass. The quick response

Model F892QR Sprinklers utilize a 3

mm diameter frangible bulb. Table A

indicates the bulb liquid color as a

function of temperature rating.

NOTES

Inquiries concerning the appropriate-

ness of wax, lead, or polyester coated

sprinklers for a given corrosive envi-

ronment should be submitted to the

attention of the Technical Services

Department.

Wax, lead, or polyester coated sprin-

klers are not suitable for use in open

sprinkler corrosive environments.

INSTALLATION

NOTE

Do not install any bulb type sprinkler

if the bulb is cracked or there is a loss

of liquid from the bulb. With the

sprinkler held horizontal, a small air

bubble should be present. The diame-

ter of the air bubble is approximately

1/16 inch (1,6 mm) for the

135°F/57°C to 3/32 inch (2,4 mm) for

the 286°F/141°C rating.

The Model F892QR Sprinklers must

be installed in accordance with the fol-

lowing instructions.

1. With pipe thread sealant applied to

the pipe threads, hand tighten the

F892QR Sprinkler into the sprinkler

fitting.

2. Using the W-Type 3 (End A) Sprin-

kler Wrench (Ref. Fig. B) applied to

the sprinkler Wrench Flats (Ref. Fig.

A), tighten the F892QR Sprinkler

into the sprinkler fitting.

NOTE

A leak tight 3/4 inch NPT sprin-

kler joint should be obtained with

a torque of 10 to 20 ft.lbs. (13,4 to

26,8 Nm). Higher levels of torque

may distort the sprinkler inlet

with consequent leakage or im-

pairment of the sprinkler.

CARE AND MAINTENANCE

Model F892QR Sprinklers must be

maintained and serviced in accord-

ance with the following instructions:

NOTES

Before closing a fire protection system

control valve for maintenance work

on the fire protection system which it

controls, permission to shut down the

affected fire protection system must be

obtained from the proper authorities

and all personnel who may be affected

by this action must be notified.

Sprinklers which are found to be leak-

ing or exhibiting visible signs of corro-

sion must be replaced.

Automatic sprinklers must never be

shipped or stored where their tempera-

tures will exceed 100°F/38°C and they

must never be painted, plated, coated

or otherwise altered after leaving the

factory. Modified sprinklers must be

replaced. Sprinklers that have been

exposed to corrosive products of com-

bustion, but have not operated, should

be replaced if they cannot be com-

pletely cleaned by wiping the sprinkler

with a cloth or by brushing it with a soft

bristle brush.

Care must be exercised to avoid dam-

age to the sprinklers — before, during,

and after installation. Sprinklers dam-

aged by dropping, striking, wrench

twist/slippage, or the like, must be re-

placed. Also, replace any sprinkler that

has a cracked bulb or that has lost

liquid from its bulb (ref. Installation

Section Note).

Frequent visual inspections are rec-

ommended to be initially performed for

wax and/or lead coated sprinklers, af-

ter the installation has been com-

pleted, to verify the long term potential

integrity of the sprinkler coatings.

Thereafter, annual inspections per

NFPA 25 should suffice; however, in-

stead of inspecting from the floor level,

a random sampling of close-up visual

inspections should be made, so as to

better determine the exact sprinkler

condition and the long term integrity of

the wax and/or lead coating, as it may

be affected by the corrosive conditions

present.

The owner is responsible for the in-

spection, testing, and maintenance of

their fire protection system and de-

vices in compliance with this docu-

ment, as well as with the applicable

standards of the National Fire Protec-

tion Association (e.g., NFPA 25), in

QKp

=

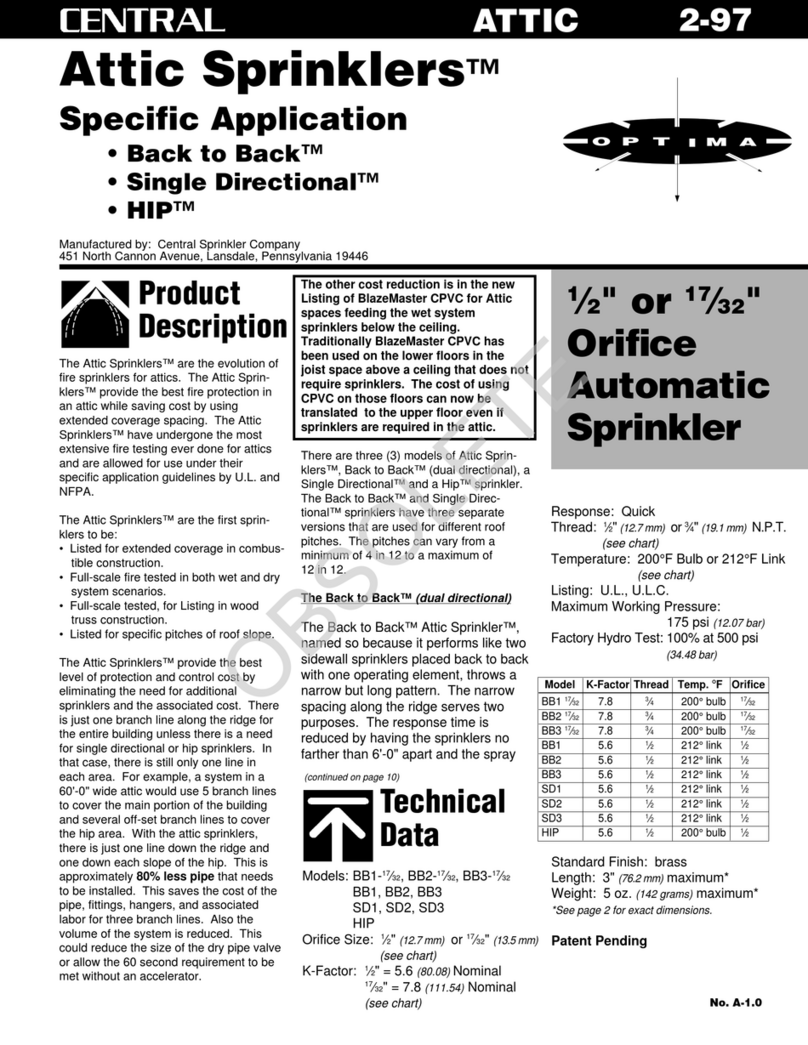

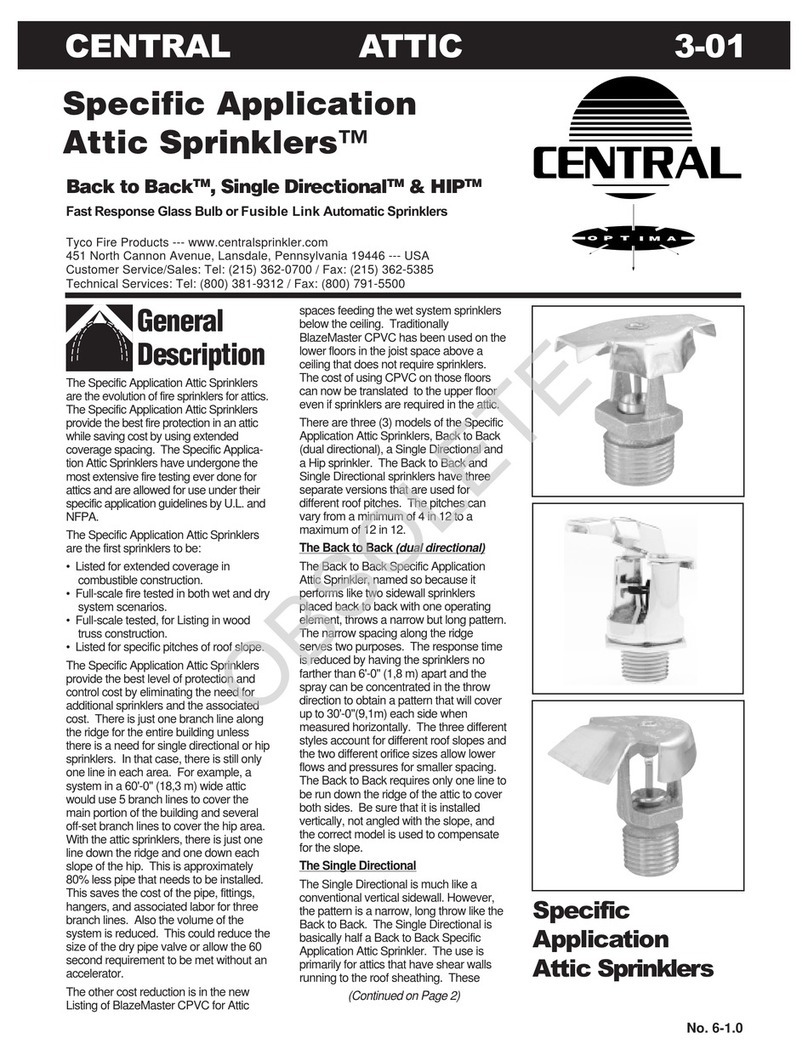

FIGURE B

W-TYPE 3 SPRINKLER

WRENCH

"FITTIN

SIDE"

FITTING

TOWARDS SPRINKLER

RECESS

WRENCH

(END "A")

DuPont Registered Trademark