TFP1241

Page 3 of 4

Operating

Procedure

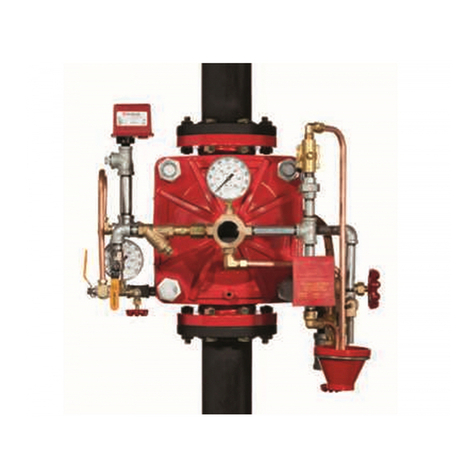

Place the TYCO Model AMD-3 Auto-

matic Nitrogen Maintenance Device

in operation in accordance with this

section.

Step 1. Determine the pressure that

meets the minimum requirements of

the system to pressurize.

Step 2. Close the control valve in the

air supply trim to the system.

Step 3. Turn the Two-Stage Pressure

Regulator adjusting handle counter-

clockwise until the adjusting spring

pressure is fully released.

Step 4. Standing to the side of the

nitrogen cylinder opposite from the

Pressure Regulator, slowly crack open

the Cylinder Control Valve until the cyl-

inder pressure is indicated on the High

Pressure Gauge and then fully open

the Cylinder Control Valve to seal its

packing.

Step 5. Slowly turn the Two-Stage

Pressure Regulator handle clockwise

until the Outlet Pressure Gauge indi-

cates the required pressure established

in Step 1.

Step 6. Open the By-Pass Valve in the

Model AMD-3 Device.

Step 7. Open the control valve in the air

supply trim to the system.

Step 8. After the system pressure sta-

bilizes, note the value on the system

pressure gauge and compare it with the

requirement. Adjust the Pressure Regu-

lator, as required (counter-clockwise to

decrease and clockwise to increase).

One-half turn of the stem changes the

outlet pressure by approximately 8 psi.

Step 9. If the system pressure must be

decreased, first re-adjust the Pressure

Regulator, then momentarily open a

connection to the system to reduce the

pressure to below the required value.

Allow the system pressure to automati-

cally stabilize.

Step 10. Close the By-Pass Valve in the

Model AMD-3 Device.

NOTICE

Following a sprinkler operation, in order

to prevent a delay in the release of the

automatic control valve, the By-Pass

Valve must be closed when the fire pro-

tection system is in service.

Step 11. Check all supply pressure

connections for leaks.

Care and

Maintenance

The TYCO Model AMD-3 Automatic

Nitrogen Maintenance Device must

be maintained and serviced in accor-

dance with this section, in addition to

any specific requirements of the NFPA.

Any impairment must be immediately

corrected.

Before closing a fire protection system

main control valve for maintenance

work on the fire protection system

that it controls, obtain permission to

shut down the affected fire protection

system from the proper authorities

and notify all personnel who may be

affected by this action.

It is recommended that a spare supply

of nitrogen be kept on hand.

Make no attempt to field-repair or

replace any component of the Pres-

sure Regulator.

Inspections should be made more

frequently, after the system is initially

placed in service, to develop a guide-

line as to the required schedule for

nitrogen cylinder replacement. Graph-

ing the Inlet Gauge pressure noted

during each inspection will assist in

this evaluation.

After placing a fire protection system

in service, notify the proper authorities

and advise those responsible for moni-

toring proprietary and/or central station

alarms.

The owner is responsible for the

inspection, testing, and maintenance of

their fire protection system and devices

in compliance with this document, as

well as with the applicable standards

of the NATIONAL FIRE PROTECTION

ASSOCIATION (e.g., NFPA 25), in addi-

tion to the standards of any authorities

having jurisdiction. Contact the install-

ing contractor or product manufacturer

with any questions.

Automatic sprinkler systems should be

inspected, tested, and maintained by a

qualified Inspection Service in accor-

dance with local requirements and/or

national code.

INSPECTION PROCEDURE

The Model AMD-3 Automatic Nitrogen

Maintenance Device must be inspected

quarterly in accordance with the follow-

ing instructions.

Step 1. Verify that the control valve

in the air supply trim to the system is

open.

Step 2. Verify that the nitrogen Cylinder

Control Valve is open.

Step 3. Verify that the By-Pass Valve

is closed.

NOTICE

Following a sprinkler operation, in order

to prevent a delay in the release of the

automatic control valve, the By-Pass

Valve must be closed when the fire pro-

tection system is in service.

Step 4. Verify that the system pressure

gauge indicates the same value as the

previously established requirement. If

not, re-adjust per Step 8 of the Operat-

ing Procedure section.

Step 5. Verify that the Inlet Pressure

Gauge of the Pressure Regulator

indicates sufficient nitrogen cylinder

pressure. It is recommended that the

nitrogen cylinder be replaced whenever

its pressure falls to 200 psi or below.

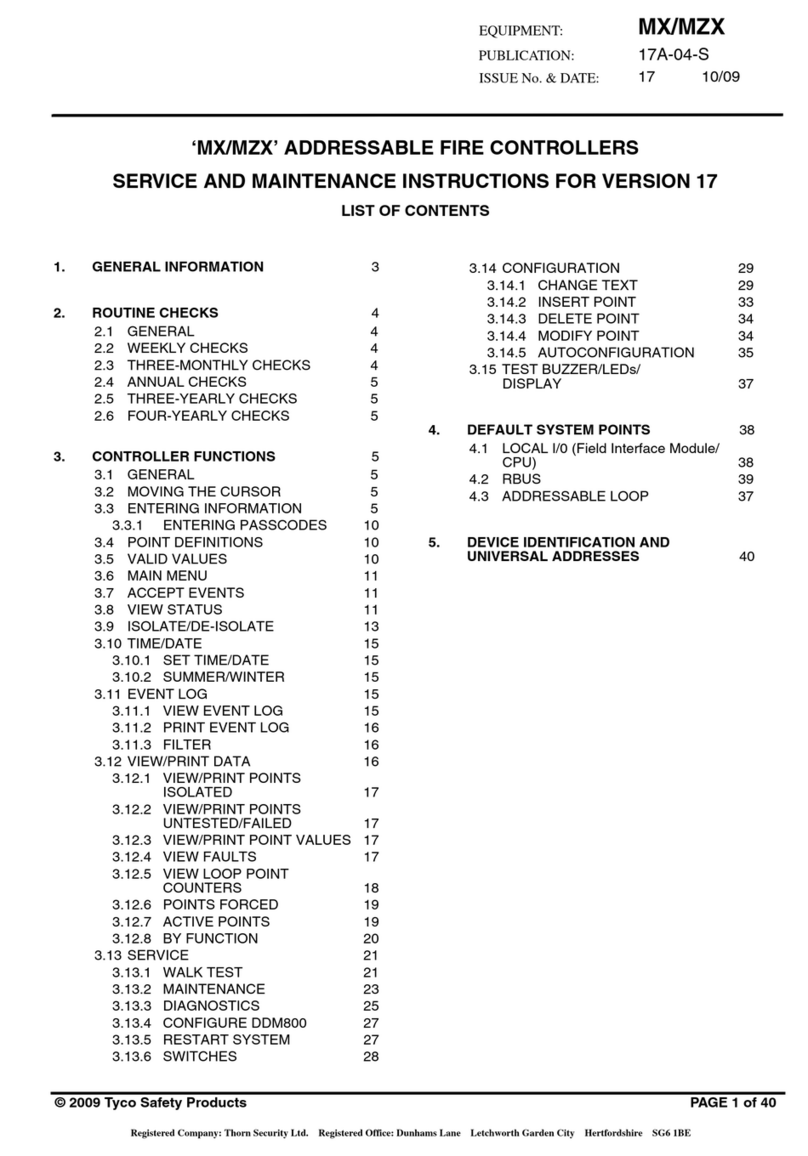

6050403020100

-60

-50

-40

-30

SYSTEM PRESSURE, PSIG

*BASED ON A DEWPOINT OF -60°F AT ATMOSPHERIC PRESSURE.

NITROGEN, °F

GRAPH A

MAXIMUM DEWPOINT OF SUPPLY NITROGEN AS A

FUNCTION OF SYSTEM PRESSURE*