3

Section 2: Installation

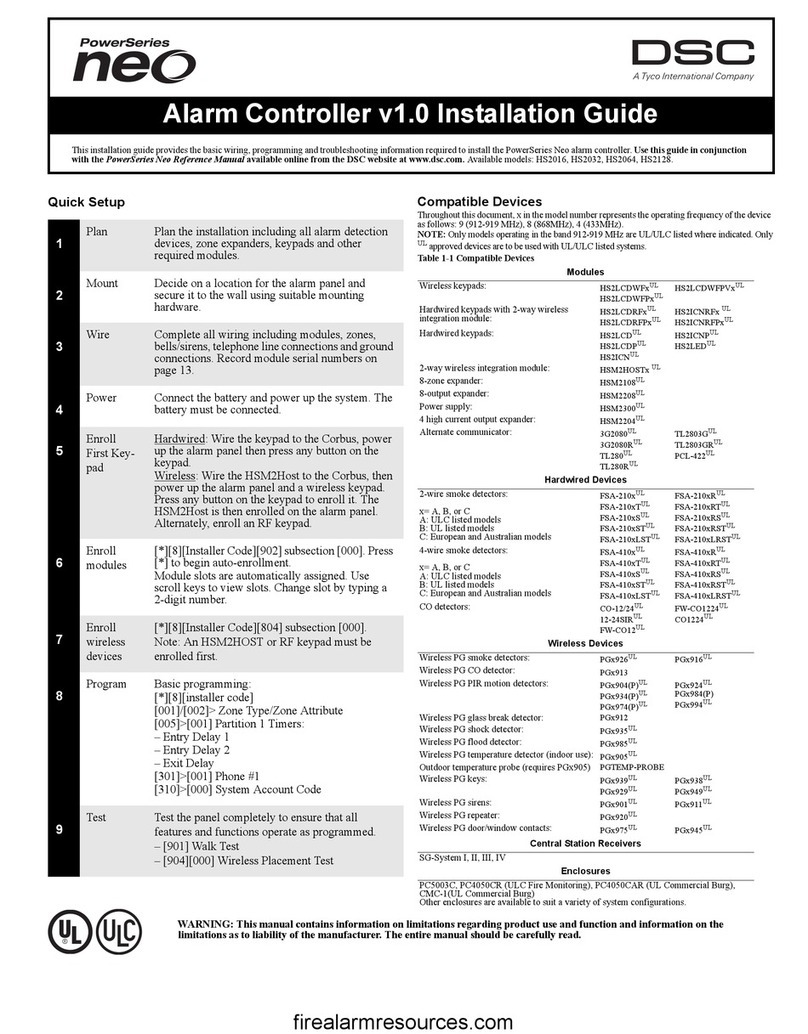

2.1 Overview of Installation Process

The steps below are provided to assist with the installation of the

alarm system. Read over this section briefly to get an overall under-

standing of the order of installation. Working from this plan can help

reduce problems and reduce the overall time required for installation.

Step 1 – Create a Layout

Draw a rough sketch of the site and include all alarm detection

devices, zone expanders, keypads and other required modules.

Step 2 – Mount the Panel

Decide on a location for the alarm panel and secure it to the wall

using suitable mounting hardware. See 2.2.1 Mounting the Enclosure

on page 3.

Step 3 – Wire the Alarm Controller

Wire each of the modules to the alarm controller following the guide-

lines provided in section 2.3.3 Corbus Wiring on page 4.

Step 4 – Wire Zones

Complete all zone wiring. Follow the guidelines provided in section

2.4.8 Zone Wiring on page 6 to connect zones using normally closed

loops, single EOL resistor, double EOL resistors, fire zones and key-

switch arming zones.

Step 5 – Complete Wiring

Complete all other wiring including bells or sirens, telephone line

connections, ground connections or any other wiring necessary. Fol-

low the guidelines provided in section 2.3.1 Terminal Descriptions

on page 3.

Step 6 – Power up the Control Panel

Once all zone and alarm controller wiring is complete, connect the

battery and power up the system. The alarm controller will not power

up if only the battery is connected.

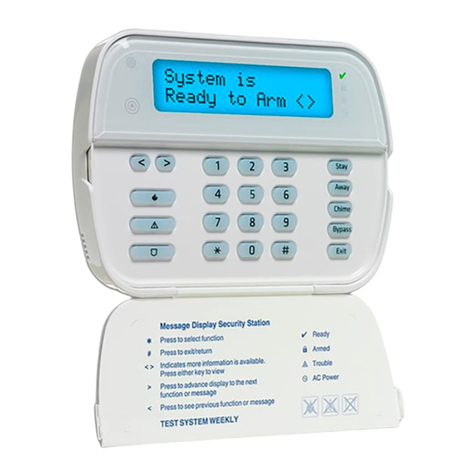

Step 7 – Enroll Keypads and Modules

All keypads must be enrolled in order to operate on the system. To

enroll the first keypad, see page 11. To enroll optional keypads, see

page 52.

Step 8 – Confirm Module Supervision

By default, all modules are supervised upon installation. Supervision

is enabled at all times. To confirm that each module is properly

supervised, see [903] Confirm Module on page 54.

Step 9 – Enroll Wireless Devices

Wireless devices are enrolled via the wireless transceiver module

(HSM2HOSTx) or RF keypad and Installer Programming section

[804]. See [804] Wireless Programming on page 52 to enroll wireless

devices.

Step 10 – Program the System

Section 5 on page 24 provides a complete description of how to pro-

gram the alarm controller. It contains complete descriptions of the

various programmable features and options. Fill out the program-

ming worksheets starting on page 57 completely before attempting to

program the system.

Step 11 – Test the System

Test the panel completely to ensure that all features and functions

operate as programmed.

2.2 Alarm Controller Installation

Begin the installation by mounting the alarm controller in the metal

enclosure using the stand-offs provided. Optional modules, such as

the HSM2108 and HSM2208, can also be mounted in the enclosure.

Install hardware in the sequence indicated on the following pages.

2.2.1 Mounting the Enclosure

Locate the panel in a dry area, preferably near an unswitched AC

power source and the incoming telephone line. Complete all wiring

before applying AC or connecting the battery.

2.3 Wiring

All wiring entry points on the enclosure are designated by arrows. All

circuits are classified UL power limited except for the battery leads.

Minimum 1/4” (6.4mm) separation must be maintained at all points

between power limited and non-power limited wiring and connections.

2.3.1 Terminal Descriptions

The following terminals are available on the PowerSeries Neo alarm

controller.

Terminal Description

AC Power terminals.

Connect the battery before connecting

the AC. Do not connect the battery or

transformer until all other wiring is

complete.

BAT+, BAT- Battery terminals. Use to provide backup

power and additional current when sys-

tem demands exceed the power output of

the transformer, such as when the system

is in alarm.

Do not connect the battery until all other

wiring is complete.

AUX+, AUX- Auxiliary terminals. Use to power

modules, detectors, relays, LEDs, etc.

(700mA MAX). Connect the positive side

of device to AUX+, the negative side to

AUX-.

BELL+, BELL- Bell/Siren power. Connect the positive

side of any alarm warning device to

BELL+, the negative side to BELL-.

RED, BLK, YEL, GRN Corbus terminals. Use to provide

communication between the alarm

controller and connected modules. Each

module has four Corbus terminals that

must be connected to the Corbus.

PGM1 to PGM4 Programmable output terminals. Use to

activate devices such as LEDs.

(PGM1, PGM3, and PGM4: 50mA

PGM2: 300mA or can be configured as an

input)

Z1 to Z8

COM

Zone input terminals. Ideally, each zone

should have one detection device; how-

ever, multiple detection devices can be

wired to the same zone.

TIP, RING, T-1, R-1 Telephone line terminals.

EGND Earth ground connection.

PCLINK_1 DLS/SA

PCLINK_2 DLS/SA, Alternate Communicator