Tyco Software House iSTAR eX User manual

Other Tyco Controllers manuals

Tyco

Tyco Galaxy SC Controller User manual

Tyco

Tyco TL880LE User manual

Tyco

Tyco iSTAR Ultra G2 SE User manual

Tyco

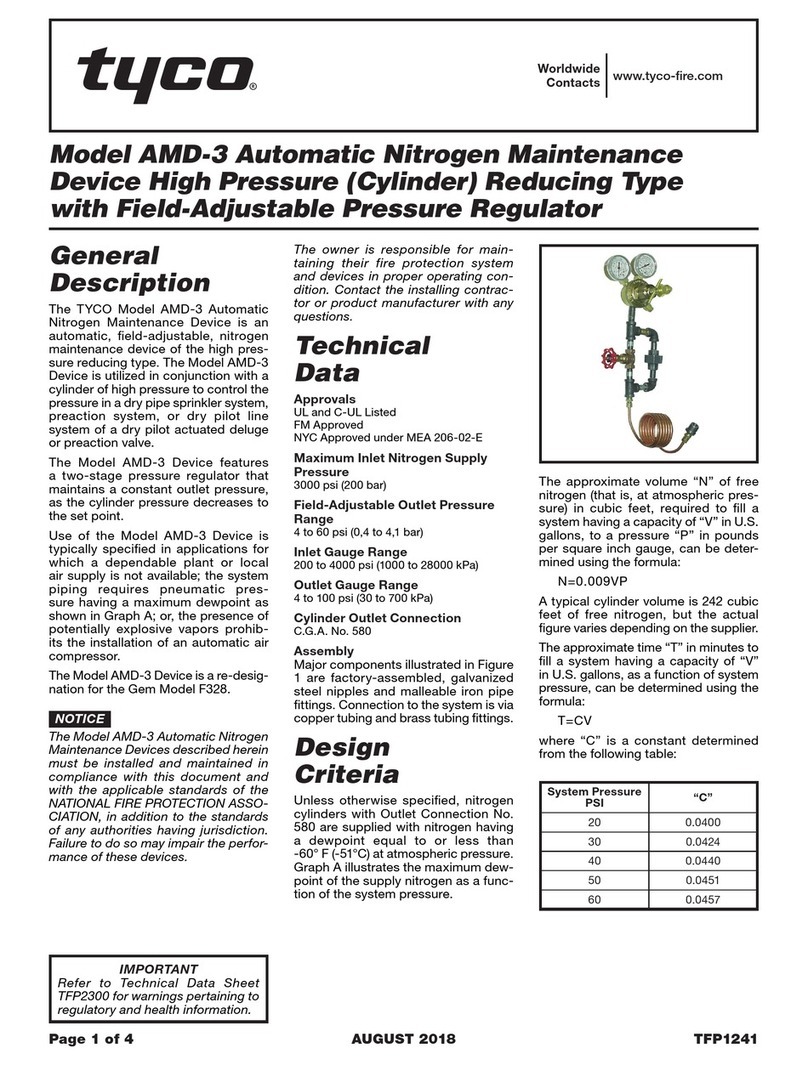

Tyco AMD-3 User manual

Tyco

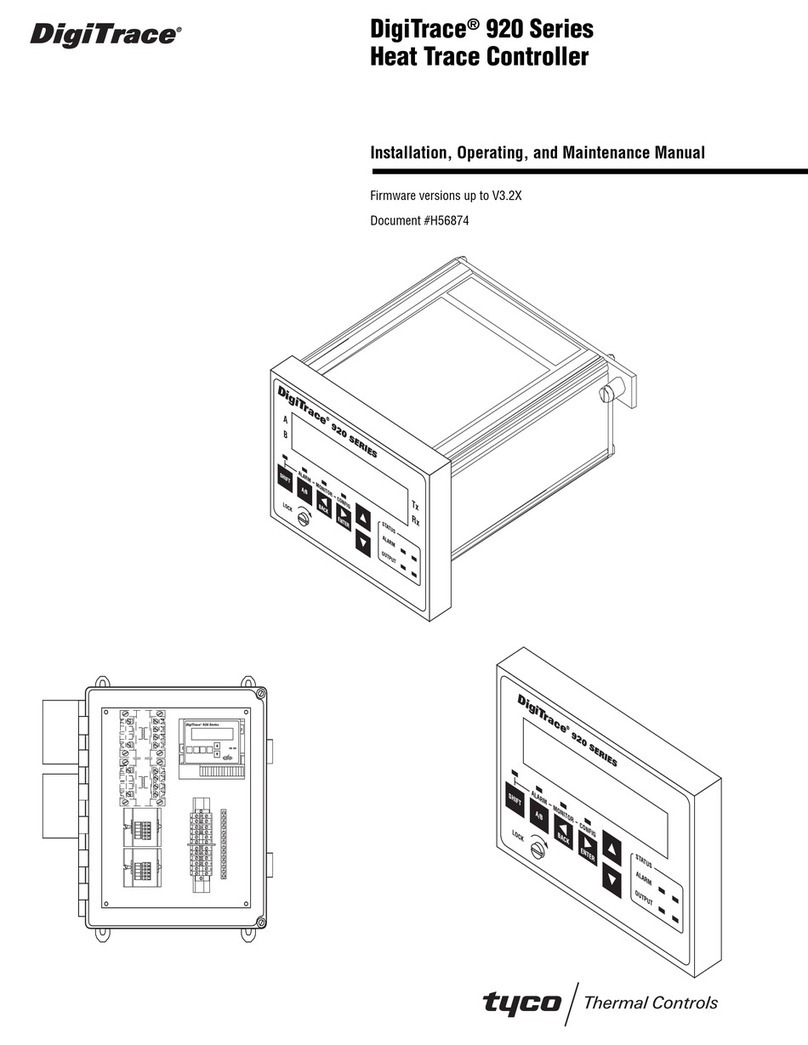

Tyco DigiTrace 920 Series Installation guide

Tyco

Tyco SCOTT EZ Flo + User manual

Tyco

Tyco G2 User manual

Tyco

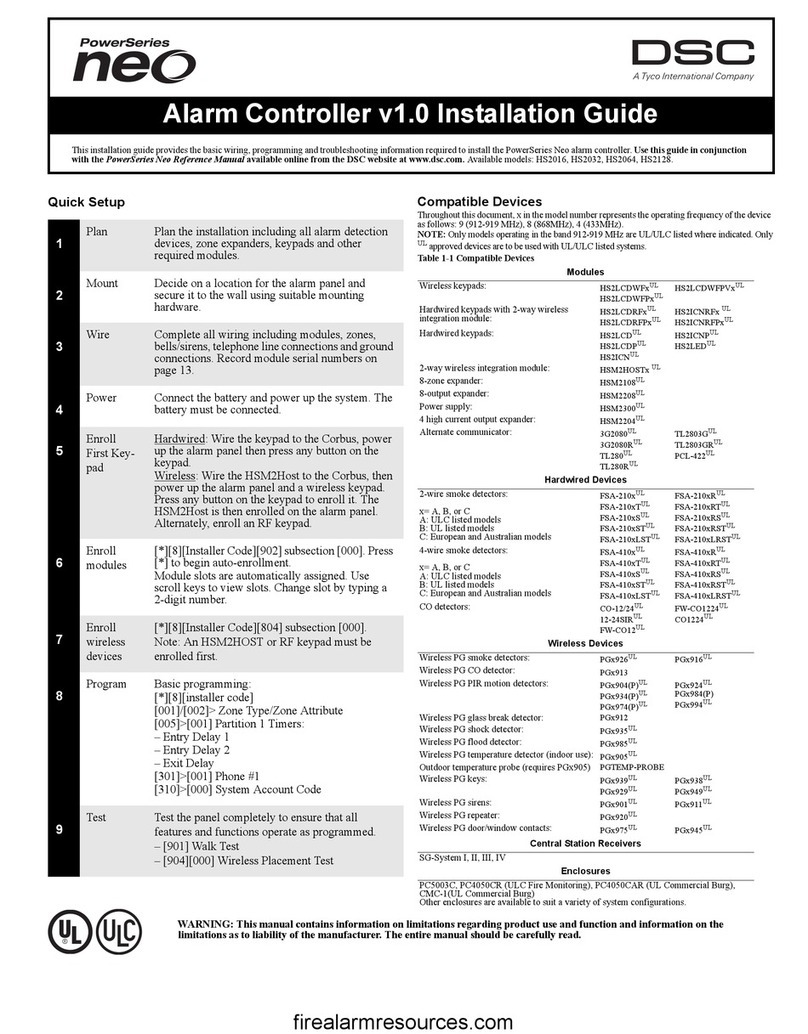

Tyco DSC PowerSeries neo User manual

Tyco

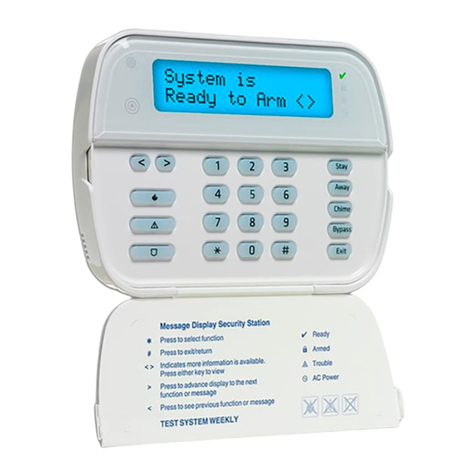

Tyco DSC WT5500 User manual

Tyco

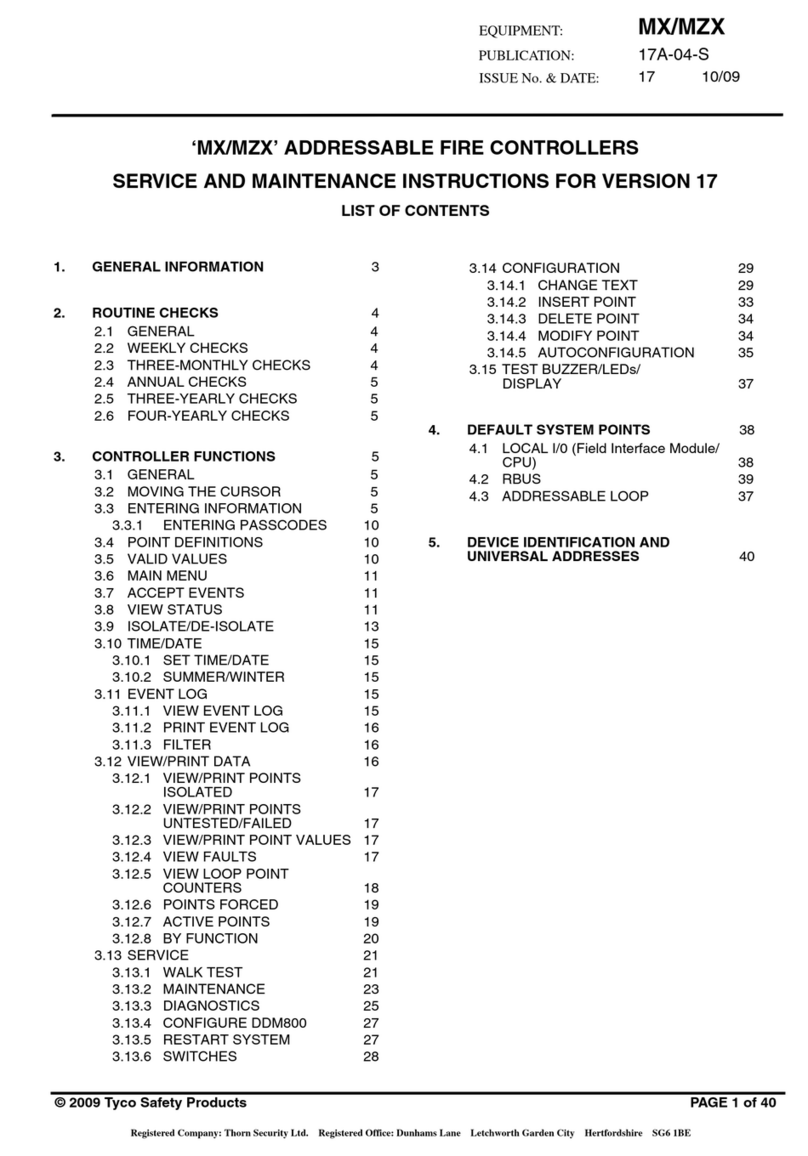

Tyco MX Series Installation and user guide

Popular Controllers manuals by other brands

Digiplex

Digiplex DGP-848 Programming guide

YASKAWA

YASKAWA SGM series user manual

Sinope

Sinope Calypso RM3500ZB installation guide

Isimet

Isimet DLA Series Style 2 Installation, Operations, Start-up and Maintenance Instructions

LSIS

LSIS sv-ip5a user manual

Airflow

Airflow Uno hab Installation and operating instructions