General

Description

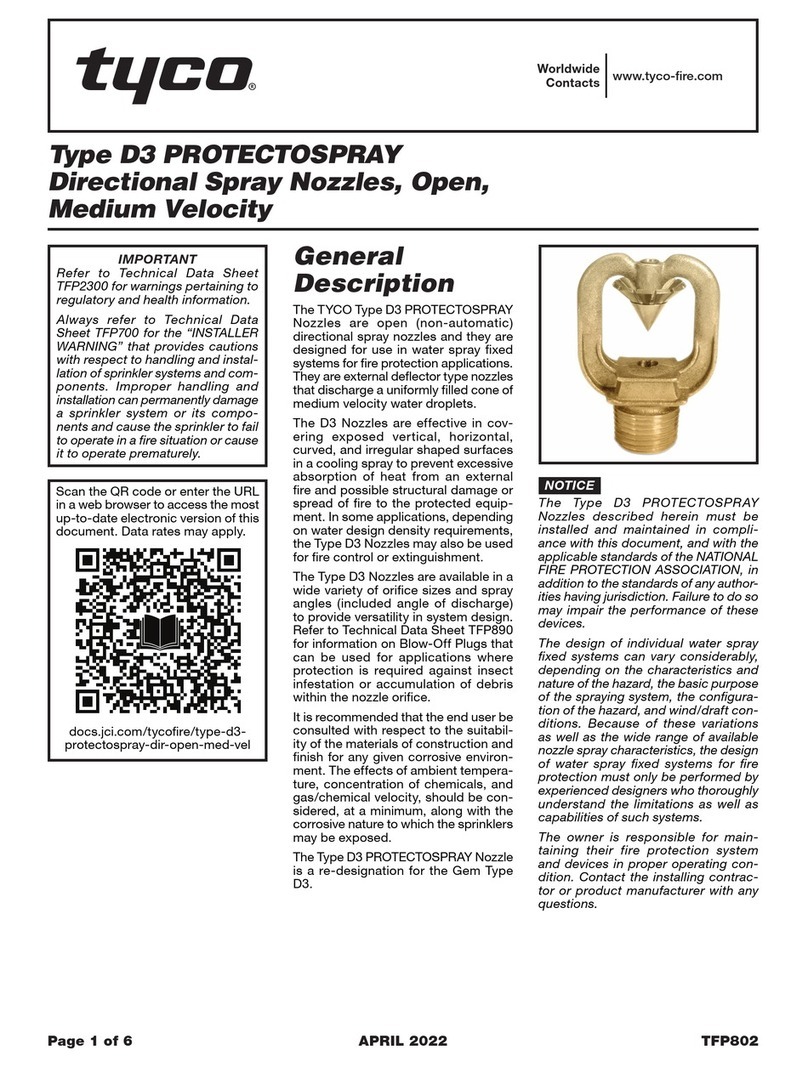

The TYCO Model FSC 80 K-factor Flush

Sprinkler Concrete Sprinklers are quick

response spray sprinklers designed for

use in areas such as ofces, hospitals,

churches, schools, apartments, and

hotels.

• For applications in poured concrete

ceiling/oor assemblies, a unique

Installation Cup is used to form the

recessed cavity into which the FSC

Sprinkler is installed

•

The ush design is made aestheti-

cally appealing by concealing the

deector and other operating parts

above the link assembly. The FSC

Sprinklers, with heat sensitive sol-

der type release elements, are rated

quick response sprinklers

NOTICE

The TYCO Model FSC 80 K-factor

Flush Sprinkler Concrete Sprinklers

described herein must be installed

and maintained in compliance with this

document and with the applicable stan-

dards CEA 4001 “Sprinkler Systems:

Planning and Installation” or EN12845

“Fixed Firefighting Systems - Automatic

Sprinkler Systems - Design, Installation

and Maintenance”, in addition to the

standards of any authorities having ju-

risdiction. Failure to do so may impair

the performance of these devices.

Tyco Fire Protection Products specifi-

cally disclaims any liability for damages

or injury (including death) arising out of

Physical Characteristics

Frame ..............................Brass

Deector Assembly . . . . . . . . . . . . . . . . . . Bronze

Sealing Assembly ........... Beryllium Nickel

with TEFLON

Link Assembly . . . . . . . . . . . . . . . . . . . . . Copper

Button .............................Brass

Deector Guide Pins . . . . . . . . . . . . . . . Stainless

Steel

Bridge...................... Stainless Steel

Levers...................... Stainless Steel

Plug ..............................Plastic

Escutcheon ......................... Steel

Installation Cup Assembly.............Plastic

Sprinkler Extension Thread.............Brass

Thread Adapter ......................Brass

Design

Criteria

General Criteria

The TYCO Model FSC 80 K-factor

Flush Sprinkler Concrete Sprinklers

are intended to be installed per CEA

4001 “Sprinkler Systems: Planning

and Installation” or EN12845 “Fixed

Fireghting Systems - Automatic

Sprinkler Systems - Design, Installation

and Maintenance” where Flush

Sprinklers are permitted. Only escutch-

eons shown in Figure 1 can be utilized

with the Model FSC 80 K-factor Flush

Sprinkler Concrete Sprinklers.

In all cases, CEA 4001 “Sprinkler

Systems: Planning and Installation” or

EN12845 “Fixed Fireghting Systems -

Automatic Sprinkler Systems - Design,

Installation and Maintenance” must be

followed to ensure proper installation.

The FSC Sprinklers can be used in nu-

merous scenarios including installation

in concrete ceilings/oors assemblies.

or caused by manipulation, dismantling,

or misuse of FSC Sprinklers or the use

or attempted use of the FSC Sprinklers

or any component thereof as an instru-

ment unrelated to its intended function

as a fire protection device.

The owner is responsible for maintain-

ing their fire protection system and de-

vices in proper operating condition.

The installing contractor or manufac-

turer should be contacted with any

questions.

Sprinkler

Identification

Number (SIN)

TY3200

Technical

Data

Approvals

VdS Approved

Flush Sprinkler Concrete is VdS

approved for installation per CEA

4001 “Sprinkler Systems: Planning

and Installation” or EN12845 “Fixed

Fireghting Systems - Automatic

Sprinkler Systems - Design, Installa-

tion and Maintenance”.

Maximum Working Pressure

12,1 bar (175 psi)

Discharge Coefficient

80,6 LPM/bar1/2 (K=5.6 GPM/psi1/2)

Temperature Rating

74°C (165°F)

Finishes

Sprinkler: White/Gray

Escutcheon: White/Gray

Model FSC 80 K-factor

Flush Sprinkler Concrete

Quick Response Standard Coverage

Page 1 of 6 OCTOBER 2012 TFP645

IMP O RTA NT

Always refer to Technical Data

Sheet TFP700 for the “INSTALLER

WARNING” that provides cautions

with respect to handling and

installation of sprinkler systems and

components. Improper handling and

installation can permanently damage

a sprinkler system or its components

and cause the sprinkler to fail to

operate in a fire situation or cause it

to operate prematurely.

Worldwide

Contacts

www.tyco-fire.com