may be used to install sprinklers with

1/2 NPT connections. Higher levels of

torque may distort the sprinkler inlet

and cause leakage or impairment of

the sprinkler.

Do not attempt to make-up for insuffi-

cient adjustment in the escutcheon

plate by under- or over-tightening the

sprinkler. Readjust the position of the

sprinkler fitting to suit.

The Series EC-5 Sidewall Sprinklers

must be installed in accordance with

the following instructions.

Step 1. Horizontal sidewall sprinklers

are to be installed with their centerline

perpendicular to the back wall and par-

allel to the ceiling. The word “TOP” on

the deflector is to face towards the

ceiling.

Step 2. With pipe thread sealant ap-

plied to the pipe threads, hand tighten

the sprinkler into the sprinkler fitting.

Step 3. Tighten the sprinkler into the

sprinkler fitting using only the W-Type

6 Sprinkler Wrench (Ref. Figure 3).

With reference to Figures 1, the W-

Type 6 Sprinkler Wrench is to be ap-

plied to the sprinkler wrench flats.

The Series EC-5 Recessed Sidewall

Sprinklers must be installed in ac-

cordance with the following instruc-

tions.

Step A. Horizontal sidewall sprinklers

are to be installed with their centerline

perpendicular to the back wall and par-

allel to the ceiling. The word “TOP” on

the deflector is to face towards the

ceiling.

Step B. After installing the Style 50

Mounting Plate, as applicable, over the

sprinkler threads and with pipe thread

sealant applied to the pipe threads,

hand tighten the sprinkler into the

sprinkler fitting.

Step C. Tighten the sprinkler into the

sprinkler fitting using only the W-Type

7 Recessed Sprinkler Wrench (Ref.

Figure 4). With reference to Figure 1,

the W-Type 7 Recessed Sprinkler

Wrench is to be applied to the sprinkler

wrench flats.

Step D. After the wall has been in-

stalled or the finish coat has been ap-

plied, slide on the Style 50 Closure

over the Series EC-5 Sprinkler and

push the Closure over the Mounting

Plate until its flange comes in contact

with the wall.

Care and

Maintenance

The Series EC-5 Sprinklers must be

maintained and serviced in accord-

ance with the following instructions:

NOTES

Before closing a fire protection system

main control valve for maintenance

work on the fire protection system that

it controls, permission to shut down the

affected fire protection system must be

obtained from the proper authorities

and all personnel who may be affected

by this action must be notified.

Absence of an escutcheon, which is

used to cover a clearance hole, may

delay the time to sprinkler operation in

a fire situation.

Sprinklers that are found to be leaking

or exhibiting visible signs of corrosion

must be replaced.

Automatic sprinklers must never be

painted, plated, coated or otherwise

altered after leaving the factory. Modi-

fied sprinklers must be replaced.

Sprinklers that have been exposed to

corrosive products of combustion, but

have not operated, should be replaced

if they cannot be completely cleaned

by wiping the sprinkler with a cloth or

by brushing it with a soft bristle brush.

Care must be exercised to avoid dam-

age to the sprinklers - before, during,

and after installation. Sprinklers dam-

aged by dropping, striking, wrench

twist/slippage, or the like, must be re-

placed. Also, replace any sprinkler that

has a cracked bulb or that has lost

liquid from its bulb. (Ref. Installation

Section).

Frequent visual inspections are rec-

TFP298 Page 3 of 6

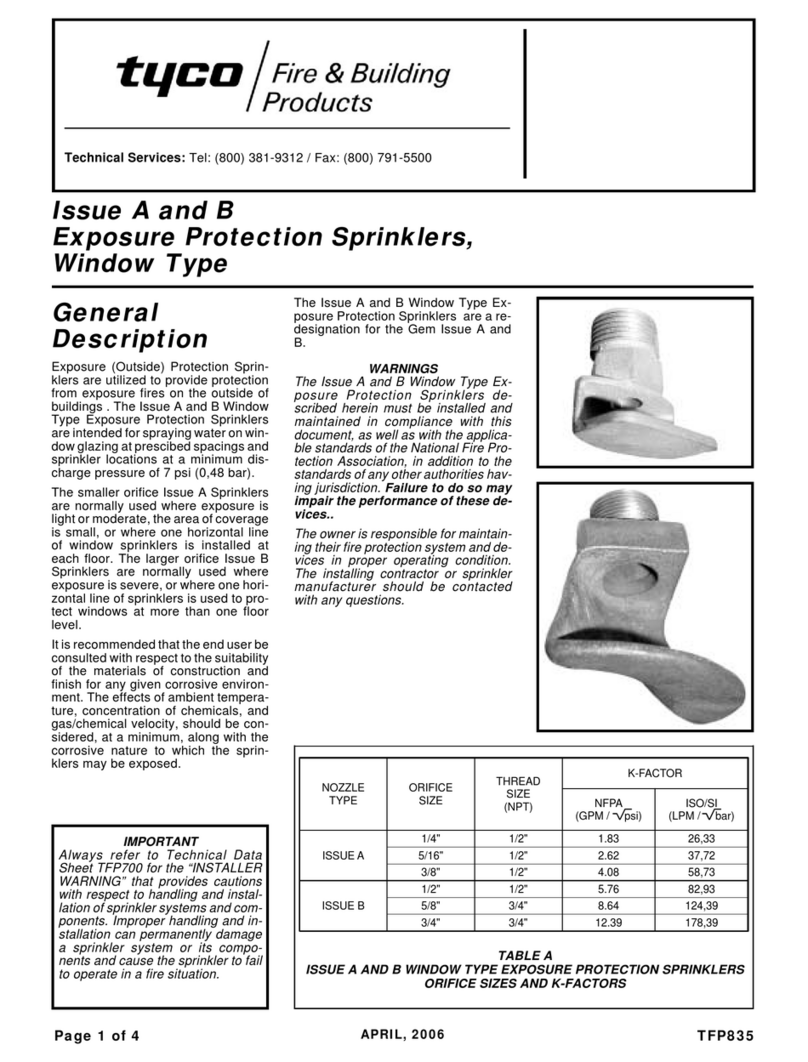

TYPE TEMP. BULB

LIQUID

NATURAL

BRASS

CHROME

PLATED

WHITE**

POLYESTER

135°F/57°CEC HSW

(TY3302)

SPRINKLER FINISH (See Note 4)

1, 2, 5Orange

Red

Yellow

155°F/68°C

200°F/93°C

NOTES:

1. Listed by Underwriters Laboratories, Inc. (UL) per Table B.

2. Listed by Underwriters Laboratories, Inc. for use in Canada (C-UL) per Table B.

3. Approved by Factory Mutual Research Corporation (FM) per Table C.

4. Where Polyester Coated Sprinklers are noted to be UL and C-UL Listed, the sprinklers

are UL and C-UL Listed Corrosion Resistant Sprinklers.

5. Approved by the City of New York under MEA 113-04-E.

* Installed with Style 50 Recessed Escutcheon.

** Frame and deflector only. Listings and approvals apply to color (Special Order).

TABLE A

LABORATORY LISTINGS AND APPROVALS

(Refer to the Design Criteria Section)

K

5.6

1/2"

NPT

1, 2, 5

5.6

1/2"

NPT

RECESSED

EC HSW*

(TY3302)

135°F/57°C

155°F/68°C

200°F/93°C

Orange

Red

Yellow

1, 2, 3, 5

1, 2, 3, 5

1, 2, 5

1, 2, 5

FIGURE 7

W-TYPE 6 SPRINKLER

WRENCH

WRENCH RECESS

(END "A" USED

FOR TY3302)

FIGURE 8

W-TYPE 7 RECESSED

SPRINKLER WRENCH

RECESS

WREN

H

WITH SPRINKLER

ENGAGEMENT

IN TO ENSURE

WREN

HIN

AREA

PUSH WRENCH