TFP800

Page 3 of 6

Operation

The glass bulb contains a uid that ex-

pands when exposed to heat. When the

rated temperature is reached, the uid

expands sufciently to shatter the glass

bulb, allowing the nozzle to activate and

water to ow.

Design

Criteria

Nozzle Placement.

Where direct impingement of water

spray onto all of the protected surface

is required by the Authority Having Ju-

risdiction, the nozzles are to be spaced

and directed so that their spray pat-

terns will completely cover the plane-

of-protection with the minimum re-

quired average density. However, it is

recommended that indoor nozzle spac-

ing be 12 feet (3,7 m) or less and that

outdoor nozzle spacing be 10 feet (3,0

m) or less. Where rundown or slippage

is planned, for example, exposure pro-

tection of vessels per NFPA 15, the

above recommended indoor and out-

door spacings also apply.

When used for protecting the surfaces

of a vessel, for example, the nozzles are

positioned normal to and approximate-

ly 2 feet (0,6 m) from the surface. This

approach, in conjunction with a prop-

erly selected spray angle, will tend to

make more effective use of the spray as

well as help minimize the disturbance

effects of wind/draft conditions on the

water spray patterns.

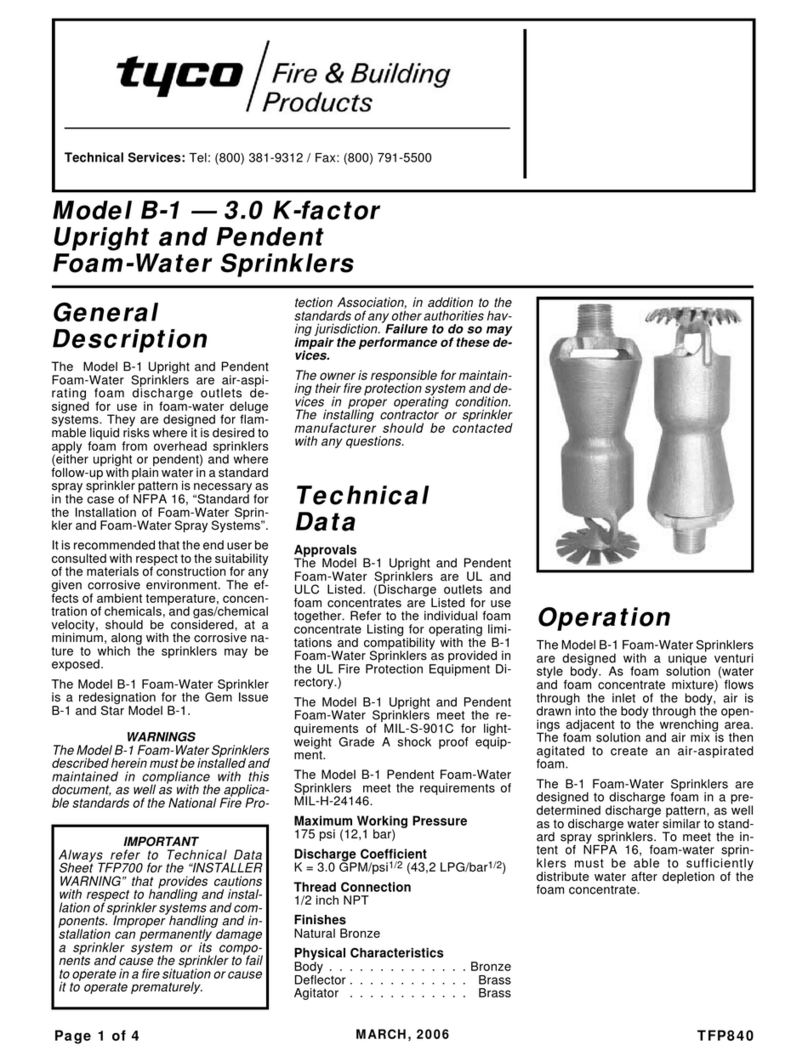

Spray Patterns.

The Design Spray Proles for the noz-

zle spray angles of 65 to 180 degrees

are shown in Figure 2 and apply to dis-

charge pressures of 20 to 60 psi (1,4

to 4,1 bar). Discharge pressures in ex-

cess of 60 psi (4,1 bar) will result in a

decrease in coverage area because the

spray patterns tend to draw inwards at

higher pressures. Refer inquiries on

higher discharge pressures to the Tech-

nical Services Department.

The maximum axial distances between

the nozzle tip and plane-of-protection,

for exposure protection, are given in

Table E and F. When the axial distance

from the nozzle tip to the plane-of-pro-

tection is 3 feet (0,6 m) or less, the De-

sign Spray Prole is the same as the

nominal spray angles of 65 thru 140

degrees.

Heat Sensitivity.

Because the Type EA-1 PROTECTO-

SPRAY Nozzles are automatic nozzles,

they must be located with consider-

ation of their ability to detect abnor-

mal temperature increases due to re.

Therefore, it is recommended that

NFPA 13 be reviewed with respect to

the rules that dene the permitted dis-

tance below ceilings and the spacing

limitations for standard coverage auto-

matic sprinklers as a function of occu-

pancy hazard.

Main Pipeline Strainers.

Main pipeline strainers per NFPA 15 are

required for systems utilizing nozzles

with a ow path less than 3/8 inch (9,5

mm) diameter, that is, K=1.4 and K=2.8

(Table A), and for any system where the

water is likely to contain obstructive

material.

5. The maximum Axial Distances shown in Tables E and F are based on exposure

protection.

4. For axial distances of 2 feet (0,6 meters) and less and for nozzle spray angles of 65° to

140°, the Design Spray Prole is the same as the nominal spray angle.

RADIAL

DISTANCE

NOTES:

1.

2.

Design data obtained from tests in still air.

Design data applies to a residual (owing) pressure range at the nozzle inlet of 20 to 60

Products Technical Services.

psi (1,4 to 4,1 bar). For pressures up to 175 psi (12,1 bar) consult Tyco Fire & Building

3.

Refer to the authority having jurisdiction for their minimum required residual pressures.

The shapes of the Design Spray Proles remain essentially unchanged over the

maximum Axial Distances shown in Tables E and F.

GRAVITY

FIXED ANGLE

(ORIENTATION)

SPRAY

PROFILE PROTECTION

PLANE OF

NOZZLE

AXIAL DISTANCE

FIGURe 2

WATeR DISTRIBUTION DeSIGN DATA

95°

65°

80°

110°

125°

140°

160°

180°

0

16

14

12

10

8

6

4

2

0

2 4 6 8

RADIAL DISTANCE FROM

NOZZLE CENTERLINE, FEET

AXIAL DISTANCE FROM NOZZLE, FEET

125°

140°

160°

95°

80°

110°

65°

180°

AXIAL DISTANCE FROM NOZZLE, METRES

RADIAL DISTANCE FROM

NOZZLE CENTERLINE, METERS

2,52,01,51,00,50

4,5

4,0

3,5

3,0

2,5

2,0

1,5

1,0

0

0,5