FM APPROVAL CRITERIA

The Model EC-25 Extended Coverage

Upright Sprinklers (TY9128) are FM

Approved to be utilized in accordance

with the following guidelines.

Application

The Model EC-25 Extended Coverage

Upright Sprinklers are FM Approved

ceiling-level Storage Sprinklers for

storage occupancy hazards and oth-

er similar high heat release type res.

When compared with other FM Ap-

proved Storage Sprinklers, the Model

EC-25 Sprinkler provides low hydraulic

demand, the spacing advantages

of extended coverage, and the FM

obstruction benets of an upright

sprinkler.

Model EC-25 Sprinklers should be

used in conformance with applicable

FM Global Property Loss Prevention

Data Sheets.

Hydraulic Design

To determine the hydraulic design for

the Model EC-25 Sprinkler refer to the

applicable FM Global Property Loss

Prevention Data Sheet.

System Type

Wet-pipe systems are acceptable.

Sprinkler Spacing

The maximum coverage area per

sprinkler is 196 ft² (18,2 m²). The mini-

mum coverage area per sprinkler is

100 ft² (9,3 m²). The maximum distance

between sprinklers is 14 ft. (4,3 m). The

minimum distance between sprinklers

is 10 ft. (3,05 m).

Note: When a wall or obstruction makes

a minimum spacing of 10 ft. (3,05 m)

impossible, consult FM Global Property

Loss Prevention Data Sheet 2.0 for ap-

plicable guidelines.

Sprinkler Location

Locate sprinklers with respect to the

ceiling/roof in accordance with FM

Global Property Loss Prevention Data

Sheet 2.0.

Obstructions

Follow the obstruction requirements

as detailed in FM Global Property Loss

Prevention Data Sheet 2.0.

Other Details

All other design details should be in

accordance with FM Global Property

Loss Prevention Data Sheet 2.0 as well

as any other applicable FM Global

Data Sheet.

Installation

The TYCO Model EC-25 Upright

Sprinklers are to be installed in accor-

dance with the following instructions:

NOTICE

Damage to the fusible Link Assembly

during installation can be avoided by

handling the sprinkler using only the

frame arms and the appropriate sprin-

kler wrench. Do not grip or apply any

force to the Fusible Link Assembly.

Damaged sprinklers must be replaced

immediately.

Obtain a leak-tight 1 inch NPT sprin-

kler joint by applying a minimum-to-

maximum torque of 20 to 30 ft.lbs.

(26,8 to 40,2 Nm). Higher levels of

torque may distort the sprinkler inlet

with consequent leakage or impair-

ment of the sprinkler.

1. Install the Model EC-25 Sprinkler

in the upright position.

2. With pipe-thread sealant applied,

hand-tighten the sprinkler into the

sprinkler tting. Do not apply any

force to the Link Assembly, and

handle the Model EC-25 Sprinkler

only by the Frame arms.

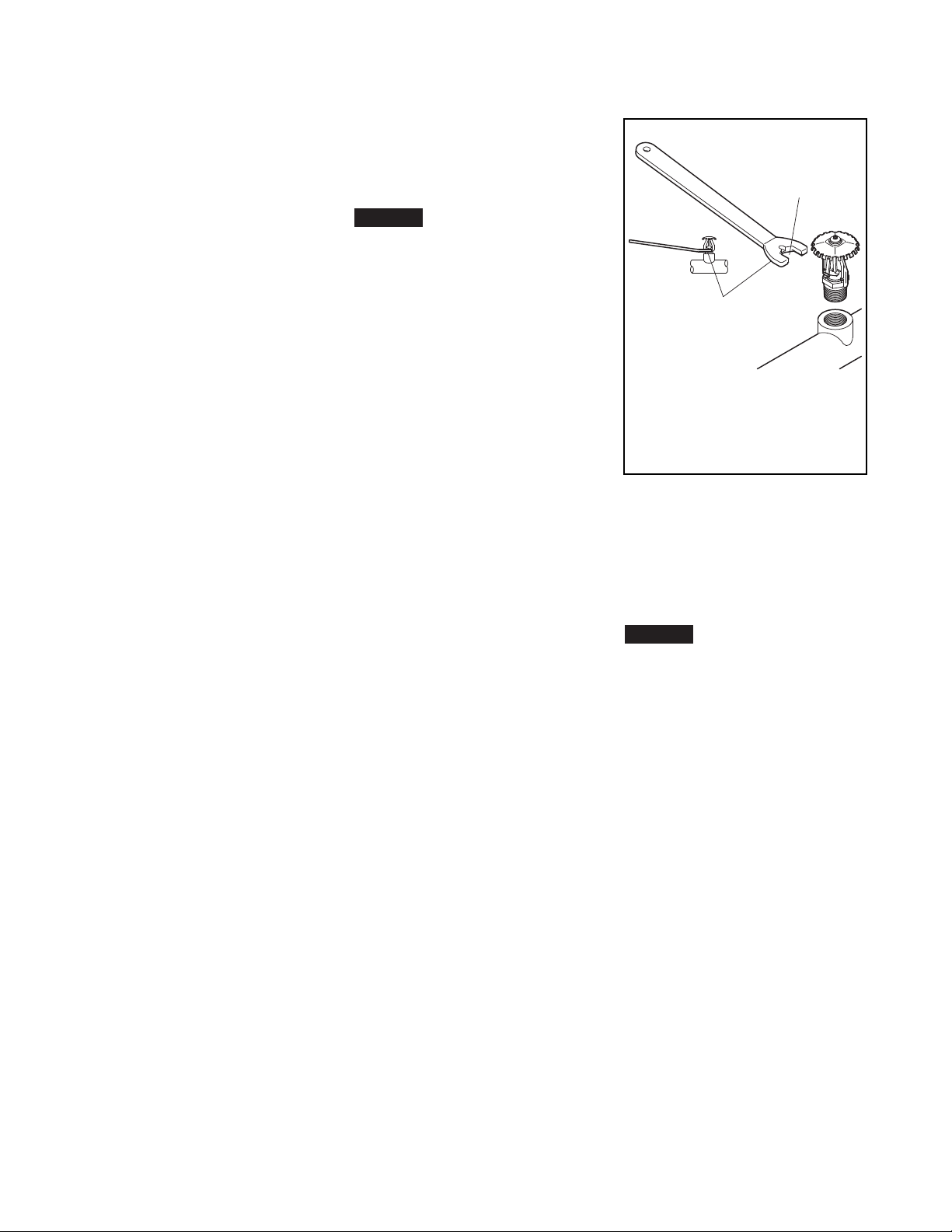

3. Wrench-tighten the Model EC-25

Sprinkler using only the W-Type 1

Sprinkler Wrench (Figure 2) and by

fully engaging (seating) the wrench

on the sprinkler Wrench Flats.

4. After installation, inspect the Link

Assembly of each Model EC-25

Sprinkler for damage. In particu-

lar, verify that the Link Assem-

bly and Hook are positioned as

illustrated in Figure 1, and that

the Link Assembly has not been

bent, creased, or forced out of

its normal position in any way.

Damaged sprinklers must be re-

placed immediately.

Care and

Maintenance

The TYCO Model EC-25 Sprinkler

must be maintained and serviced

in accordance with the following

instructions.

NOTICE

Before closing a fire protection system

main control valve for maintenance

work on the fire protection system

that it controls, obtain permission to

shut down the affected fire protection

system from the proper authorities

and notify all personnel who may be

affected by this decision.

Inspection, testing, and maintenance

must be performed as indicated be-

low and in accordance with the local

requirements and/or national codes.

Any impairment must be immediately

corrected.

Responsibility lies with owners for the

inspection, testing, and maintenance

of their re protection system and de-

vices in compliance with this docu-

ment, as well as with the applicable

standards of any authorities having ju-

risdiction. Contact the installing con-

tractor or product manufacturer re-

garding any questions.

Automatic sprinkler systems are rec-

ommended to be inspected, tested,

and maintained by a qualied Inspec-

tion Service in accordance with local

requirements and/or national codes.

"FITTING SIDE"

FITTING

TOWARDS SPRINKLER

RECESS

WRENCH

FIGURE 2

W-T Y PE 1

SPRINKLER WRENCH

TFP213

Page 3 of 4