TFP318

Page 6 of 8

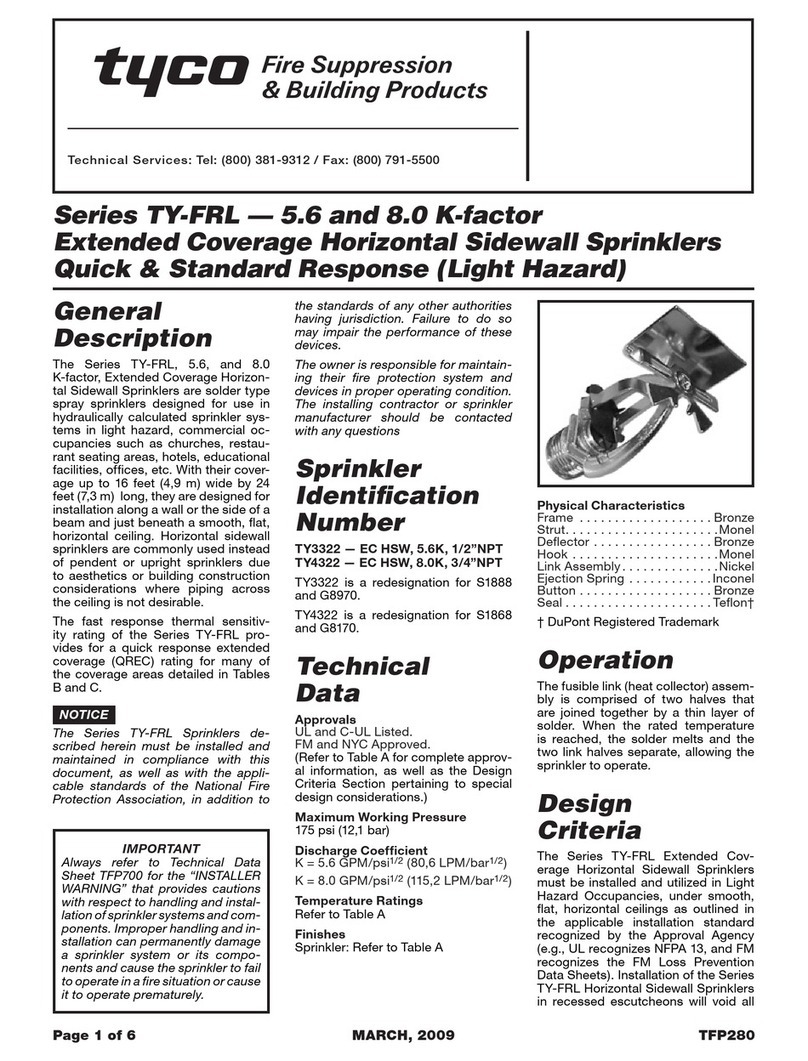

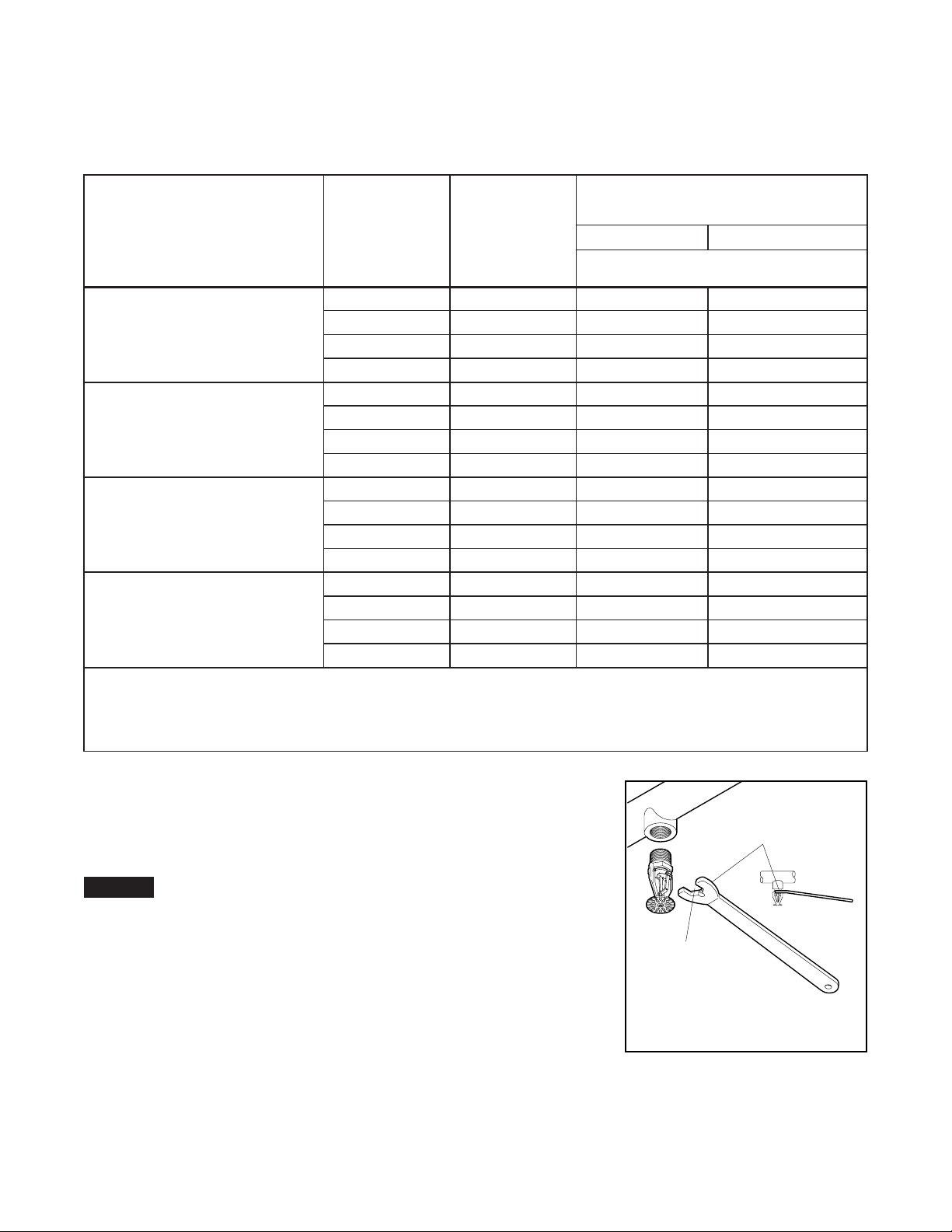

FIGURE 2

W-TYPE 1

SPRINKLER WRENCH

"FITTING SIDE"

FITTING

TOWARDS SPRINKLER

RECESS

WRENCH

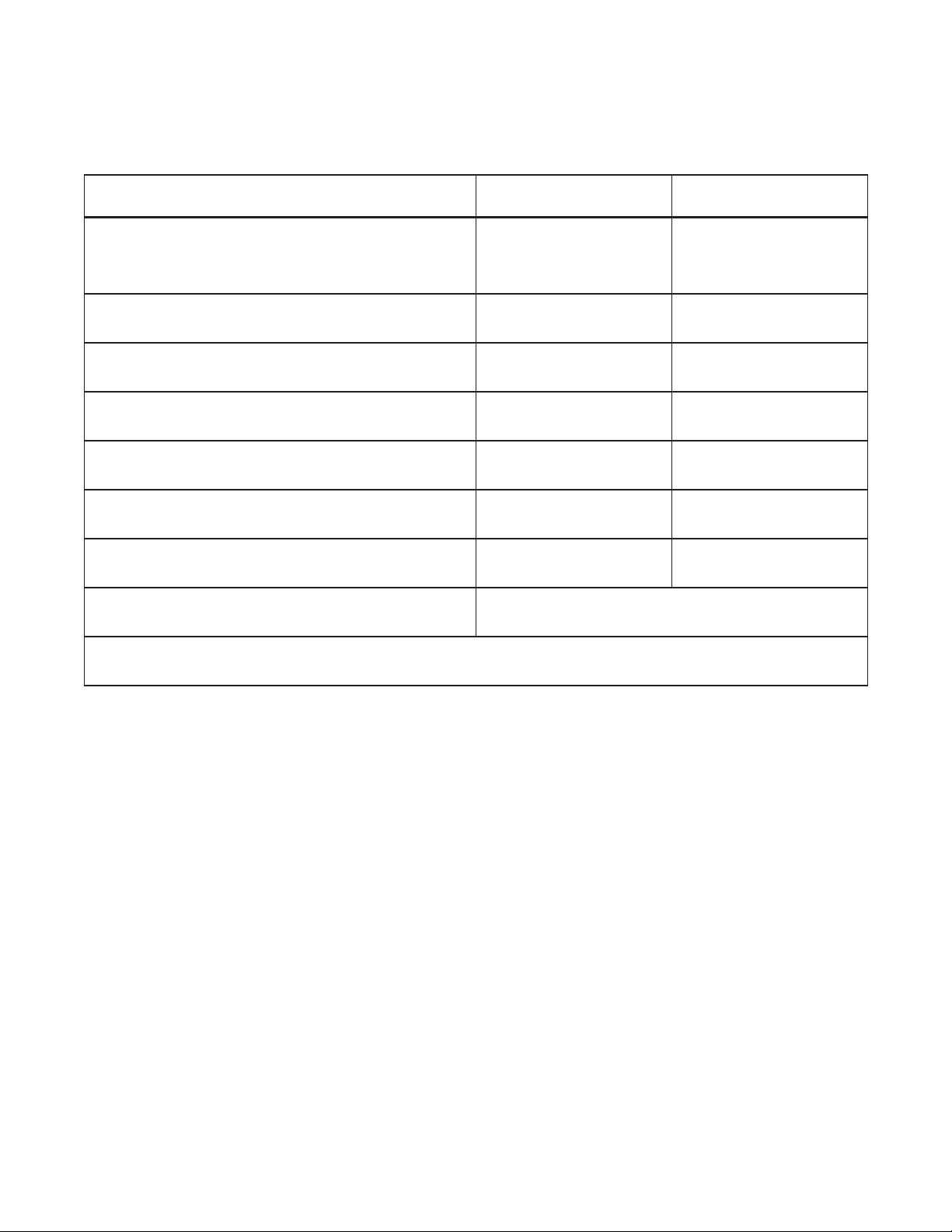

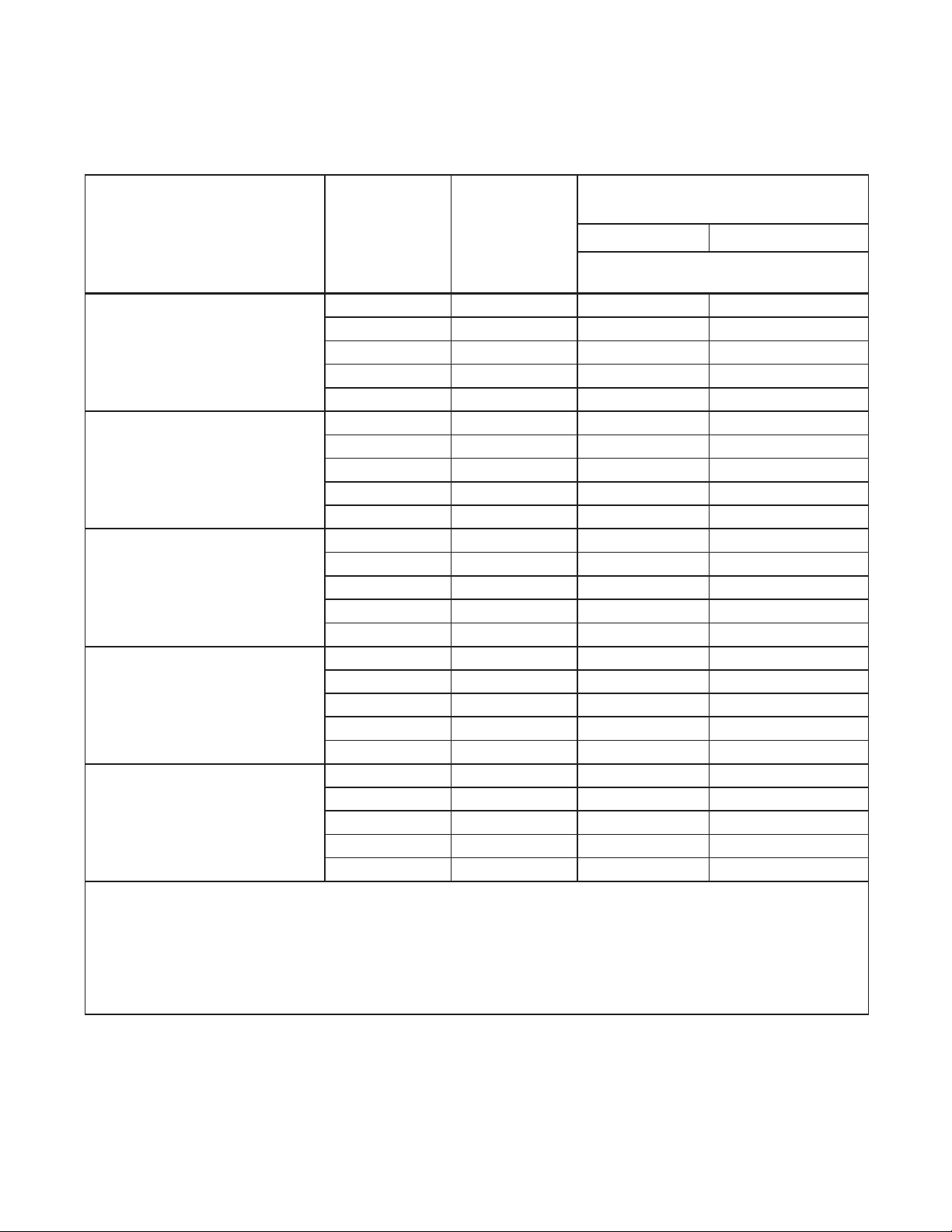

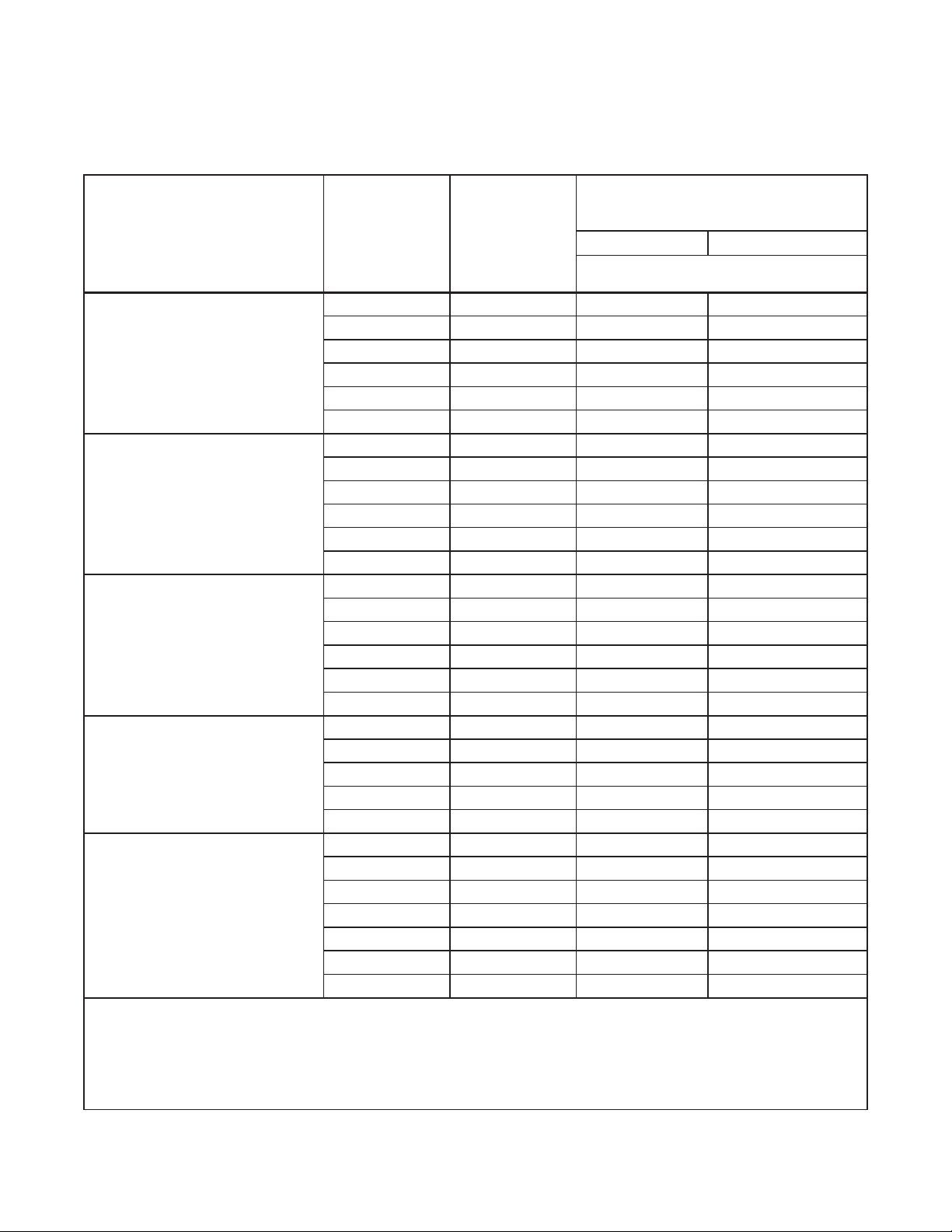

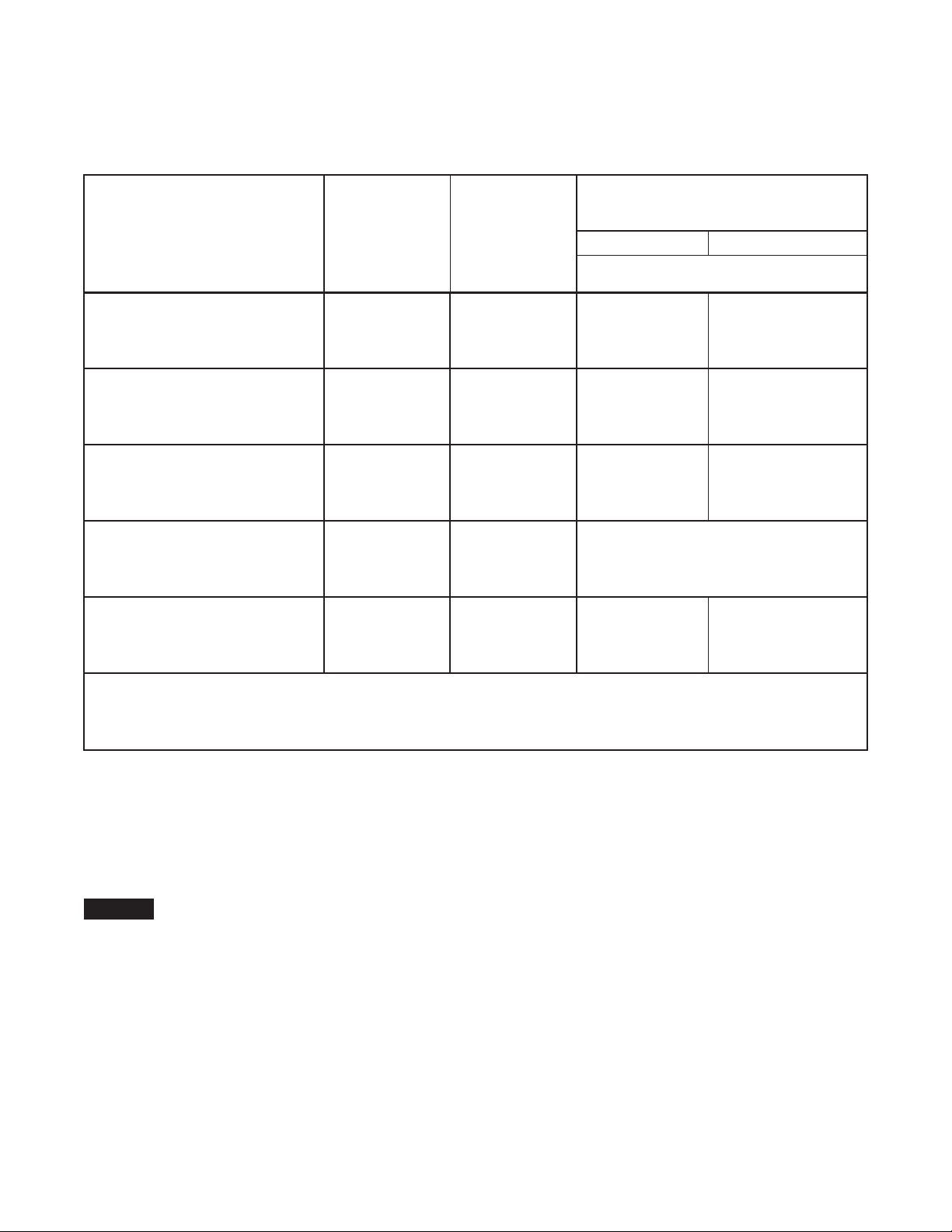

TABLE 4

NFPA AND FM DESIGN CRITERIA FOR IDLE PALLET STORAGE OF

ESFR-1 PENDENT SPRINKLERS

Commodity

Maximum

Building Height,

Ft. (m)

Maximum

Storage Height,

Ft. (m)

Minimum

Residual Pressure,

psi (bar)

NFPA FM

The number of design sprinklers at listed

pressure is 12 unless specified otherwise.

Wood on Floor

45 (13,7) 25 (7,6) N/A 90 (6,2)

40 (12,2) 35 (10,7) 75 (5,2) 75 (5,2)

32 (9,7) 25 (7,6) 60 (4,1) 75 (5,2)

30 (9,1) 25 (7,6) 50 (3,4) 50 (3,4)

Plastic on Floor

45 (13,7) 25 (7,6) N/A 90 (6,2)

40 (12,2) 35 (10,7) 75 (5,2) 75 (5,2)

32 (9,7) 25 (7,6) 60 (4,1) 75 (5,2)

30 (9,1) 25 (7,6) 50 (3,4) 50 (3,4)

Wood in Rack

45 (13,7) 40 (12,2) N/A 90 (6,2) w/IRS

40 (12,2) 35 (10,7) 75 (5,2) 75 (5,2)

32 (9,7) 25 (7,6) 60 (4,1) 75 (5,2)

30 (9,1) 25 (7,6) 50 (3,4) 50 (3,4)

Plastic in Rack

45 (13,7) 40 (12,2) N/A 90 (6,2) w/IRS

40 (12,2) 35 (10,7) 75 (5,2) 75 (5,2)

32 (9,7) 25 (7,6) 60 (4,1) 75 (5,2)

30 (9,1) 25 (7,6) 50 (3,4) 50 (3,4)

Abbreviations: N/A = Non-Applicable; IRS = In-Rack Sprinklers

References: NFPA 13, 2007 Edition, Chapter 12, Tables 12.12.1.2 (d) and 12.12.2.1

FM Global, June 2009, Property Loss Prevention Data Sheet 8-9 uses criteria for uncartoned,

unexpanded plastics, Table 2.3.7.5(a) for rack scenarios and Table 2.3.7.5(b) for on-floor scenarios

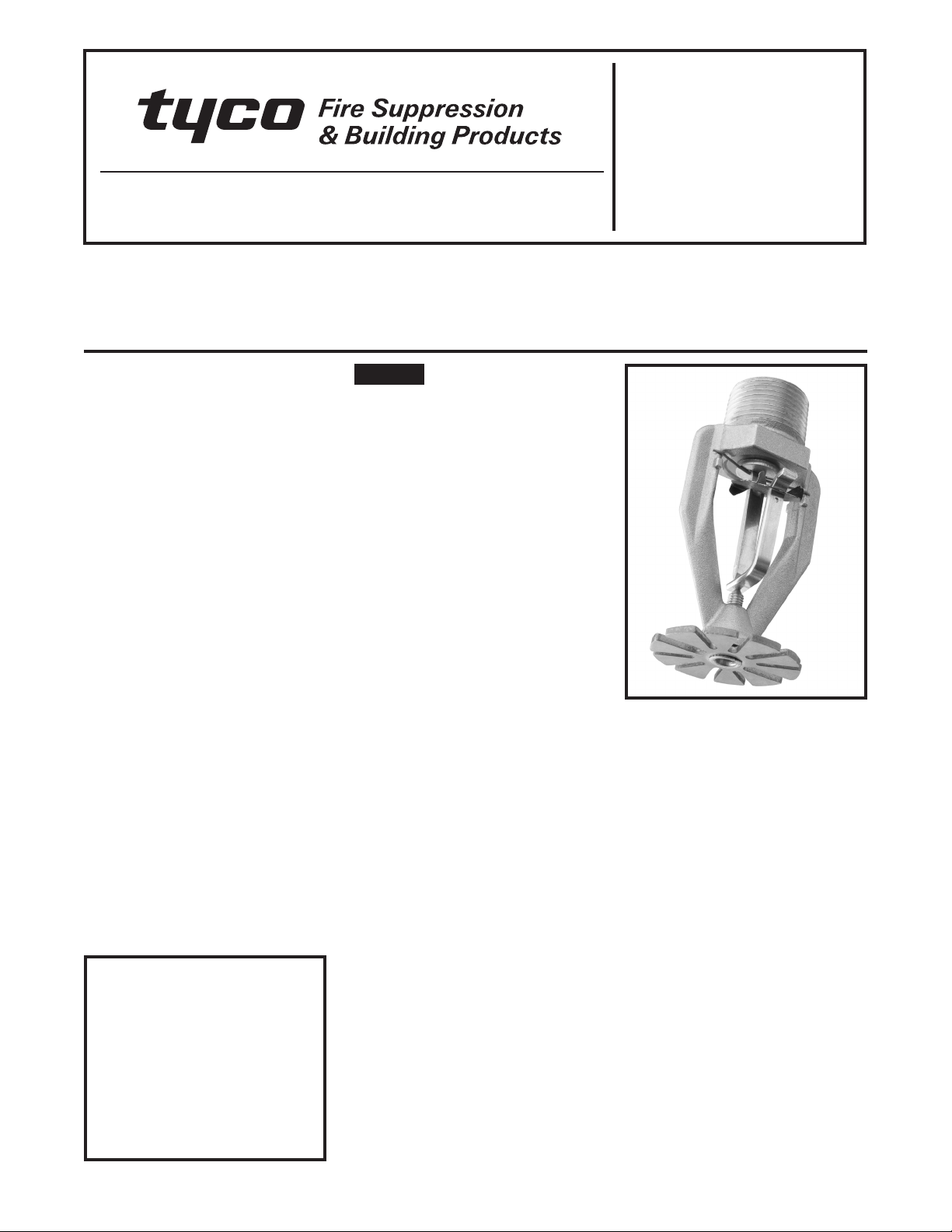

Installation

The Tyco®Model ESFR-1 Pendent

Sprinklers are to be installed in accor-

dance with the following instructions.

NOTICE

Damage to the fusible Link Assembly

during installation can be avoided by

handling the sprinkler by the frame

arms only (i.e., do not apply pres-

sure to the fusible Link Assembly),

and by using the appropriate sprinkler

wrench. Failure to do so can lead to an

unstable link assembly and premature

activation of the sprinkler. Damaged

sprinklers must be replaced.

Obtain a leak-tight 3/4 inch NPT sprin-

kler joint by applying a minimum-to-

maximum torque of 10 to 20 ft.lbs.

(13,4 to 26,8 Nm). Higher levels of

torque can distort the sprinkler inlet

with consequent leakage or impair-

ment of the sprinkler.

Step 1. Install the ESFR-1 Pendent

Sprinkler in the pendent position.

Step 2. With pipe-thread sealant ap-

plied, hand-tighten the sprinkler into

the sprinkler fitting. Do not apply pres-

sure to the Link Assembly, and han-

dle the ESFR-1 Sprinkler only by the

Frame arms.

Step 3. Wrench-tighten the ESFR-1

Sprinkler using only the W-Type 1

Sprinkler Wrench (Figure 2) and by

fully engaging (seating) the wrench on

the sprinkler wrench flats.

Step 4. After installation, inspect the

Link Assembly of each ESFR-1 Sprin-

kler for damage. In particular, verify

that the Link Assembly and Hook are

positioned as illustrated in Figure 1,

and that the Link Assembly has not

been bent, creased, or forced out of

its normal position in any way. Replace

damaged sprinklers.