Data Sheet for additional adhesive

handling recommendations. The

Material Safety Data Sheet should

be obtained from the adhesive

manufacturer via their web site

noted on the adhesive container la-

bel before using the adhesive.

In case of skin contact, flush with

water, and for eye contact seek

medical attention.

Provide adequate ventilation in area

of usage. When possible ventilation

should be achieved by the use of

local exhaust ventilation and good

general ventilation. Vapors are

heavier than air, therefore, down-

ward ventilation should be used.

When handling cyanoacrylate adhe-

sives, goggles or safety glasses

should always be worn. Polyethyl-

ene gloves should be used to pro-

tect the hands. WARNING: DO NOT

USE RUBBER OR CLOTH GLOVES.

RUBBER GLOVES WILL BOND

WHEN BROUGHT IN CONTACT

WITH THE ADHESIVE AND POROUS

COTTON GLOVES WILL ABSORB

THE ADHESIVE AND BOND THE

GLOVES TO THE SKIN.

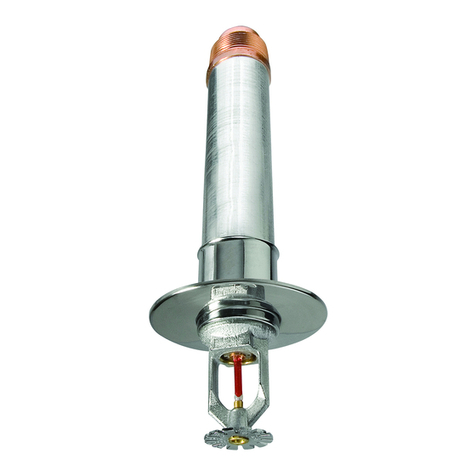

Step 1. Preparetheclearanceholeper

theapplicableTFPDrySprinklerTech-

nical Data Sheet.

Step 2. Insert the dry sprinkler through

the clearance hole and slide the Boot

over threaded inlet ofthe dry sprinkler.

When installing on Series DS-2 Dry

Sprinklers, the Boot will require

stretching. The use of a grooved cou-

pling gasket lubricant will ease instal-

lation. Use only a petroleum free sili-

cone grooved coupling gasket

lubricant to avoid freezing of the Dry

Sprinkler Boot to the Dry Sprinkler.

When sliding the Boot over the length

of the Dry Sprinkler, sliding is easily

accomplished by slightly squeezing

the Boot around the cone area.

Step 3. Thread the dry sprinkler into

the sprinkler fitting per the applicable

TFP Dry Sprinkler Technical Data

Sheet.

Refer to the sprinkler technical data

sheet for tightening torque specifica-

tions. The use of higher levels of

torque then specified may distort the

sprinkler inlet with consequent leak-

age or impairment of the sprinkler.

Step 4. Clean the contact surfaces of

the Boot and the building (ceiling or

wall)structure withadampcloth.Moist

surfaces will aid in a quick adhesion.

Use only a cloth that has been damp-

ened with water. The use of other

cleaning techniques, solvents, etc.

may render the adhesive incapable of

sealing.

Step 5. Apply the provided Adhesive

to the building structure in a zig-zag

pattern.

Refer to Warning regarding

the adhesive.

Step 6. Slide the Boot so that it comes

in contact with the building structure,

and then press the Boot firmly against

the building structure to help ensure

that the Adhesive is fully applied to

both surfaces.

When sliding the Boot over the length

of the Dry Sprinkler, sliding is easily

accomplished by slightly squeezing

the Boot around the cone area.

Step 7. Wait two minutes to allow the

Adhesive to sufficiently cure and then

apply the two Strap Ties. The Strap

Ties are to be applied to the straight

section of the Boot as shown in Figure

1 and so thatthe ends are on opposing

sides of the Boot.

The ties are to be pulled sufficiently

tight to the point that there is no gap

between Dry Sprinkler Boot and the

Dry Sprinkler. When properly installed

a paper clip or wire of similar dimen-

sion cannot be slipped between the

Dry Sprinkler Boot and the Dry Sprin-

kler.

Care and

Maintenance

The owner is responsible for the in-

spection, testing, and maintenance of

their fire protection system and de-

vices in compliance with this docu-

ment, as well as with the applicable

standards of the National Fire Protec-

tion Association (e.g., NFPA 25), in

addition to the standards of any other

authorities having jurisdiction. The in-

stalling contractor or sprinkler manu-

facturer should be contacted relative

to any questions.

It is recommended that automatic

sprinkler systems be inspected,

tested, and maintained by a qualified

Inspection Service in accordance with

local requirements and/or national

codes.

Limited

Warranty

Products manufactured by Tyco Fire &

Building Products (TFBP) are war-

ranted solely to the original Buyer for

ten (10) years against defects in mate-

rial and workmanship when paid for

and properly installed and maintained

under normal use and service. This

warranty will expire ten (10) years

from date of shipment by TFBP. No

warranty is given for products or com-

ponents manufactured by companies

not affiliated by ownership with TFBP

or for products and components which

havebeensubjecttomisuse,improper

installation,corrosion, or which have

not been installed, maintained, modi-

fied or repaired in accordance with ap-

plicable Standards of the National Fire

Protection Association, and/or the

standards of any other Authorities

Having Jurisdiction. Materials found

by TFBP to be defective shall be either

repaired or replaced, at TFBP’s sole

option. TFBP neither assumes, nor

authorizesanyperson toassume forit,

any other obligation in connection with

the sale of products or parts of prod-

ucts.TFBP shallnot beresponsiblefor

sprinkler system design errors or inac-

curate or incomplete information sup-

plied by Buyer or Buyer’s repre-

sentatives.

In no event shall TFBP be liable, in

contract, tort, strict liability or under

any other legal theory, for incidental,

indirect,specialorconsequentialdam-

ages, including but not limited to labor

charges, regardless of whether TFBP

was informed about the possibility of

such damages, and in no event shall

TFBP’s liability exceed an amount

equal to the sales price.

Theforegoingwarrantyismadeinlieu

of any and all other warranties, ex-

press or implied, including warranties

ofmerchantabilityandfitnessforapar-

ticular purpose.

This limited warranty sets forth the ex-

clusive remedy for claims based on

failure of or defect in products, materi-

als or components, whether the claim

is made in contract, tort, strict liability

or any other legal theory.

This warranty will apply to the full ex-

tent permitted by law. The invalidity, in

whole or part, of any portion of this

warranty will not affect the remainder.

Ordering

Procedure

Model DSB-1:

Specify: Model DSB-1 Dry Sprinkler

Boot*, P/N 63-000-0-001.

* Includes one Boot, two Strap Ties,

and 1/3 oz. of Adhesive (quantity of

adhesive is sufficient for installing one

Boot).

Page4of4 TFP590

TYCO FIRE & BUILDING PRODUCTS, 451 North Cannon Avenue, Lansdale, Pennsylvania 19446