PAGE 3 OF 8 1214 IH-2289

OPERATION CONTINUED

4. When zero calibration is completed,

the display shows dONE.

5. The scale exits to the active

weighing mode and displays the

actual weight value.

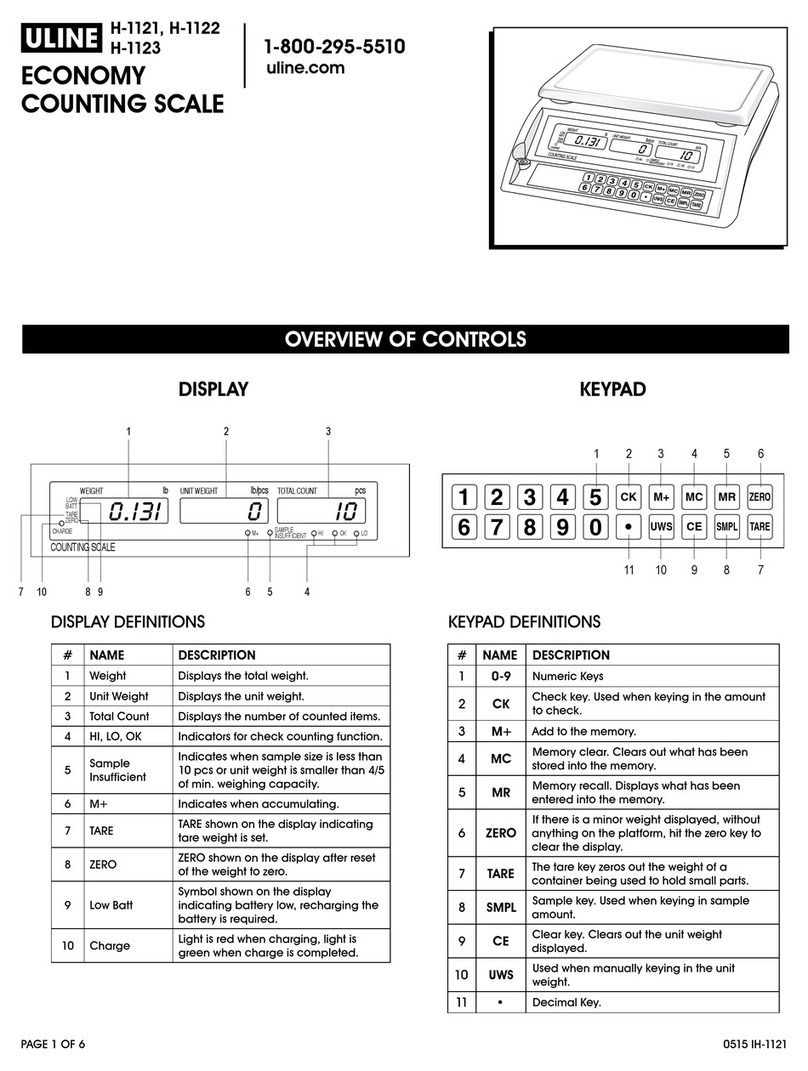

SPAN CALIBRATION

Span calibration uses two points to adjust the scale. The

span calibration point is established with a calibration

mass placed on the scale. The zero calibration point is

established with no weight on the scale.

1. When SPAN is displayed, press

the YES button to initiate Span

Calibration.

2. The display flashes the span

calibration point. Place the

specified weight on the scale and

press the YES button.

3. To choose a different span point

or calibration unit, edit the setting

as explained in Menu Navigation.

When the desired setting is

displayed, place the specified

weight on the scale and press the

YES button.

4. The display shows --C-- while the

span point is established.

5. The display flashes 0.

6. With no weight on the scale, press

the YES button to establish the zero

point.

7. The display shows --C-- while the

zero point is established.

8. When span calibration is

completed, the display shows

dONE.

9. The scale exits to the active

weighing mode and displays the

actual weight value.

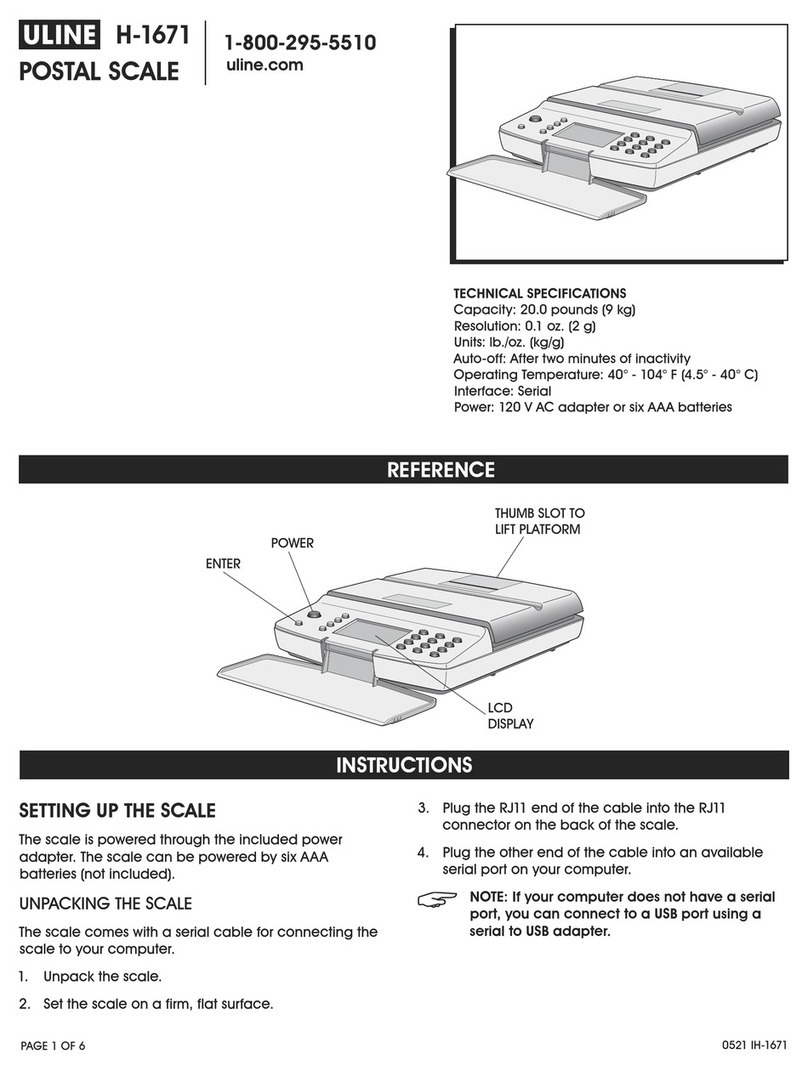

LINEARITY CALIBRATION

Linearity calibration uses 3 calibration points. The full

calibration point is established with a weight on the

scale. The mid calibration point is established with a

weight equal to half of the full calibration weight on the

scale. The zero calibration point is established with no

weight on the scale. The mid calibration points cannot

be altered by the user during the calibration procedure.

1. When LINEAr is displayed, press

the YES button to initiate linearity

calibration.

2. The display flashes the full

calibration point and calibration

unit. Place the specified weight on

the scale and press the YES button.

3. To choose a different full point or calibration unit

(kg or lb), edit the setting as explained in Menu

Navigation. When the desired setting is displayed,

place the specified weight on the scale and press

the YES button.

4. The display shows --C-- while the

full point is established.

5. The display flashes the mid

calibration point.

6. Place the specified weight on the

scale and press the YES button.

7. The display shows --C-- while the

mid point is established.

8. The display flashes 0.

9. With no weight on the scale, press

the YES button to establish the zero

point.

10. The display shows --C-- while the

zero point is established.

11. When linearity calibration is

completed, the display shows

dONE.

12. The scale exits to the active

weighing mode and displays the

actual weight value.

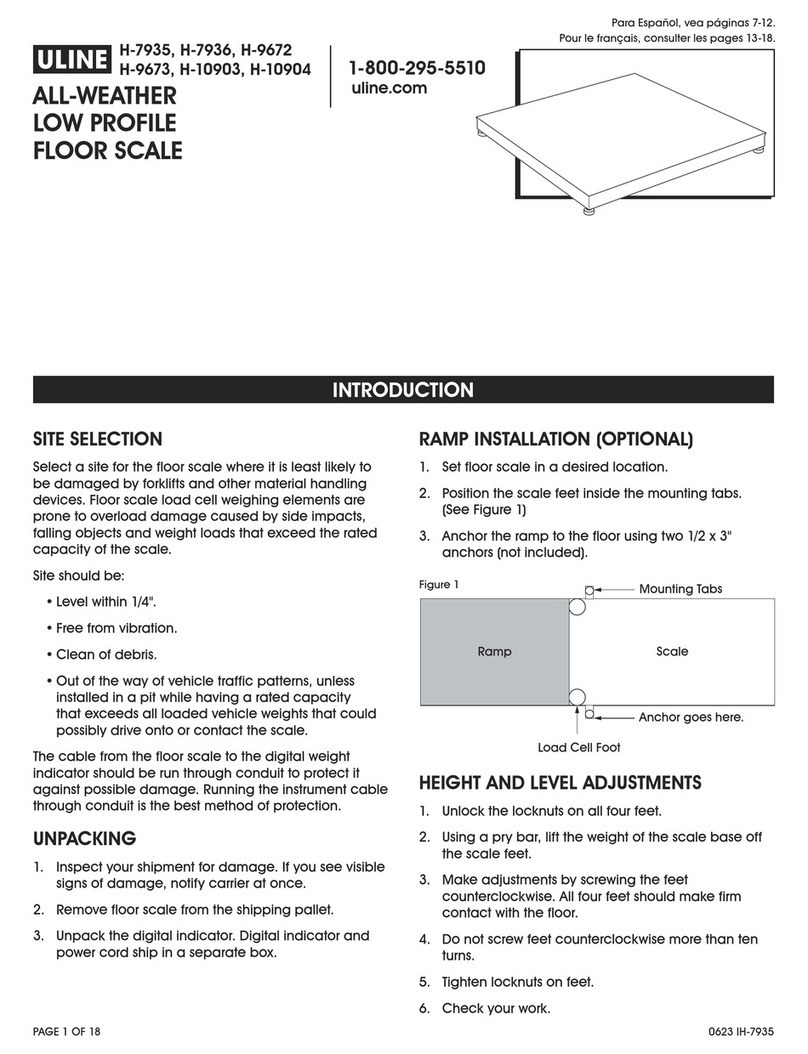

SPAN ADJUST

Span adjust uses one calibration point. The span adjust

point is established with a calibration mass placed on

the scale. Use this method to adjust the span range

without affecting the zero value.

1. When SP.Adj is displayed, press the

YES button to initiate span adjust.

2. The display flashes the span

calibration point. Place the

specified weight on the scale and

press the YES button. To choose a

different span point or calibration

point, edit the setting as explained in

Menu Navigation.

3. When the desired setting is

displayed, place the specified

weight on the scale and press the

YES button.

SPAN

--C --

--C --

L IN

dONE

30 kg

0 kg

30 kg

25 kg

. O.000 kg

--C --

--C --

--C --

dONE

15 kg

0 kg

. O.000 kg

SP.AdJ

30

kg

25

kg

dONE

. O.000 kg