PAGE 3 OF 4 1114 IH-4709

BEFORE OPERATION

The Operator Checks table below covers important

inspection points on trucks that should be checked

prior to operation. Depending on use, some trucks may

require additional checks.

WARNING! Periodic maintenance of this truck

by a qualified technician is required.

WARNING! A qualified service technician

should check the truck monthly for proper

lubrication, proper fluid levels, brake

maintenance, motor maintenance and other

areas.

WARNING! If the truck is found to be unsafe and

in need of repair, or if it contributes to an unsafe

condition, report immediately to the designated

authority. Do not operate the truck until it has

been restored to a safe operating condition.

Do not make any unauthorized repairs or

adjustments. All service must be performed by a

qualified service technician.

OPERATION

OPERATOR CHECKS

ITEM PROCEDURE

Transmission and Hydraulic Systems Check for signs of fluid leakage.

Forks Check for cracks and damage.

Guards and Load Backrest Check that safety guards are properly secured and not damaged.

Safety Signs Check that warning labels, nameplate, etc., are in good condition and legible.

Horn Check that horn sounds when operated.

Steering Check for binding or looseness in steering arm when steering.

Travel Controls Check that speed controls on control handle operate in all speed ranges in forward and

reverse and that belly button switch functions.

Wheels Check drive wheel for cracks or damage.

Move truck to check load wheels for freedom of rotation.

Hydraulic Controls Check operation of lift and lower to their maximum positions.

Brakes Check that brakes actuate when steering arm is raised to upright position and when lowered to

horizontal position.

Deadman/Parking Brake Check that steering arm raises to upright position when released and that brake applies.

Battery Disconnect Check that battery can be disconnected and reconnected. Check for connector damage.

INSTRUMENTS AND CONTROLS

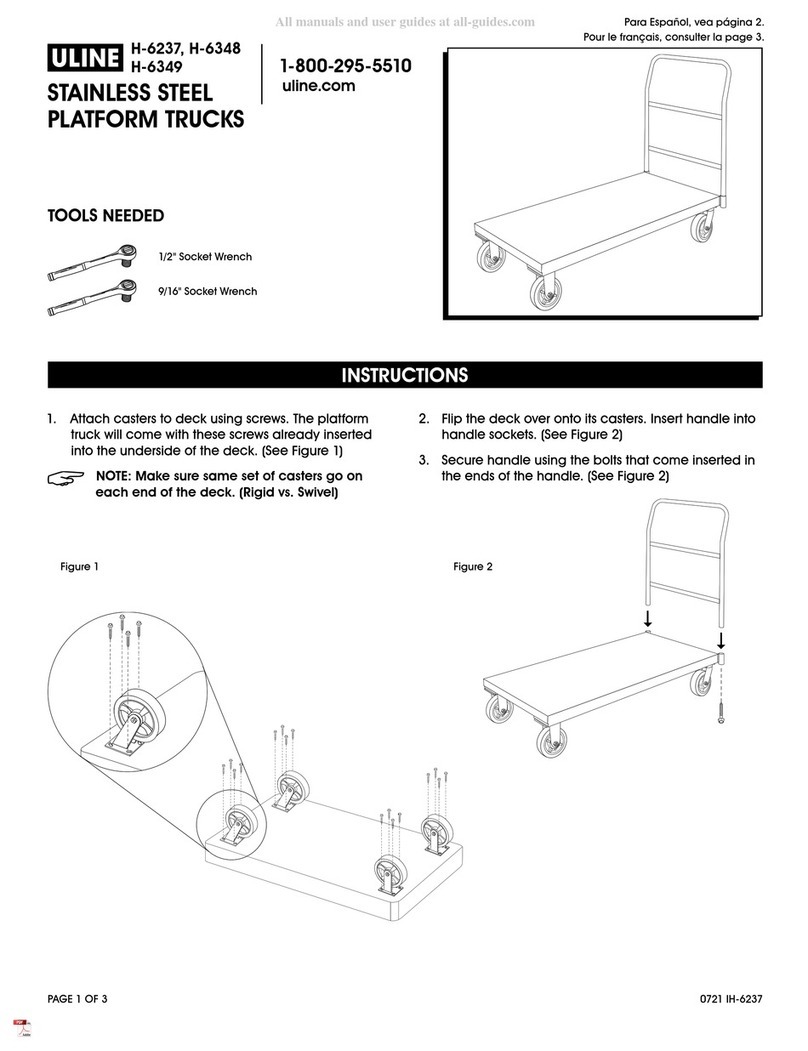

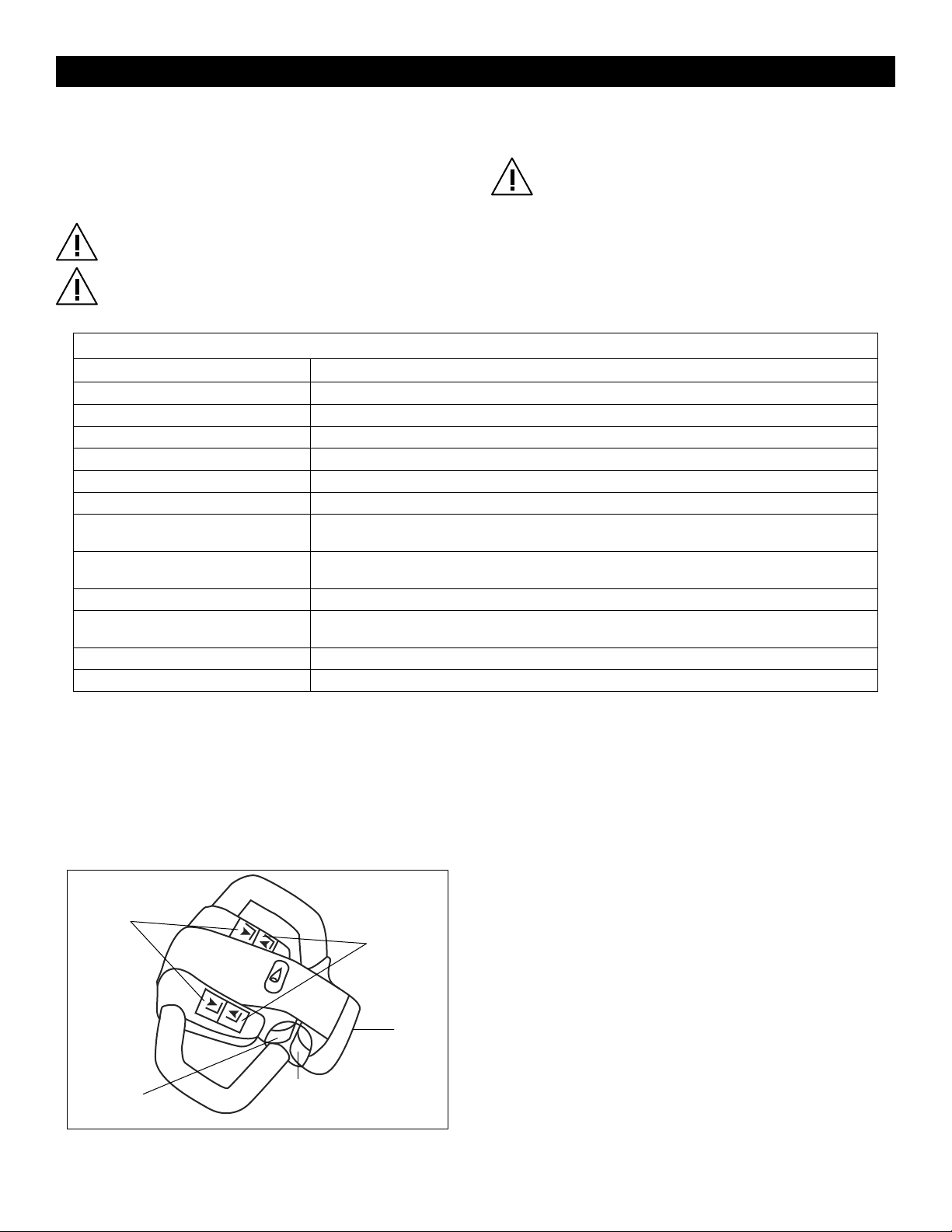

The steering arm and control handle provide controls

for steering, forward and reverse speed control, braking,

raising and lowering the forks and horn. Control handles

on all models have a “belly-button” reversing switch,

which reverses the direction of the truck upon contact

with the operator. (See Figure 4)

FORWARD AND REVERSE TRAVEL

AND SPEED CONTROL

All directional and speed controls are located on the

control handle.

Forward and reverse are controlled by rotating the

speed control lever. (See Figure 4) The lever is spring

loaded to return to neutral when released. Further

rotation in either direction will progress the truck from

slow to maximum travel speed.

To change directions or to stop the truck, rotate the

speed control lever in the opposite direction. The truck

will come to a stop, and then (unless the controls are

returned to the center neutral position) accelerate in the

opposite direction.

STEERING

Moving the control handle (which connects to the

steering arm) right or left will turn the truck right or left.

When maneuvering around corners, make square turns

and be sure there is adequate clearance.

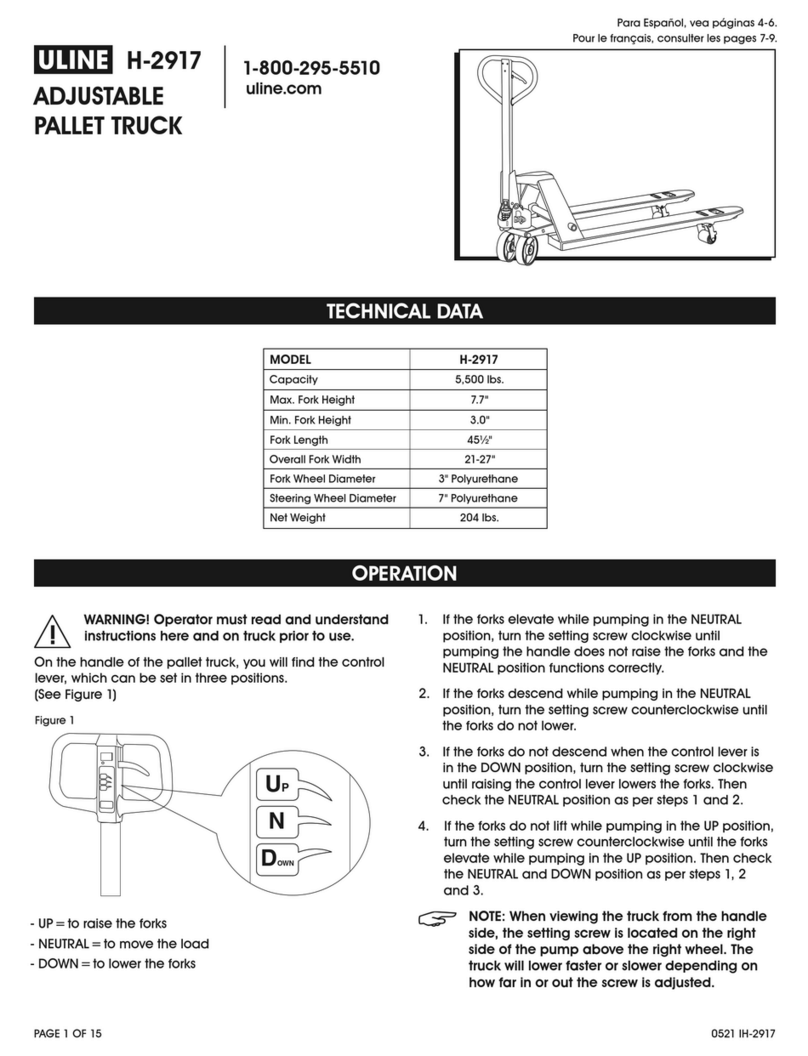

Figure 4

Lower

Buttons

Reverse

Speed

Control

Raise

Buttons

Belly

Button

Switch

Forward

Speed

Control