EVK-M8L - User guide

UBX-20028627 - R01 Page 3 of 33

C1-Public Contents

Contents

Document information................................................................................................................................2

Contents ..........................................................................................................................................................3

1Product description ..............................................................................................................................5

1.1 Overview........................................................................................................................................................5

1.2 Kit includes ................................................................................................................................................... 5

1.3 Evaluation software....................................................................................................................................5

1.4 System requirements ................................................................................................................................ 5

2Specifications .........................................................................................................................................6

2.1 Safety precautions ..................................................................................................................................... 6

3Device description.................................................................................................................................7

3.1 Interface connection and measurement................................................................................................7

3.2 Active antenna............................................................................................................................................. 7

3.3 Evaluation unit.............................................................................................................................................7

3.3.1 Antenna connector............................................................................................................................. 7

3.3.2 USB ........................................................................................................................................................8

3.3.3 UART .....................................................................................................................................................8

3.3.4 RST button........................................................................................................................................... 8

3.3.5 Safe boot button................................................................................................................................. 8

3.3.6 Slide switch .......................................................................................................................................... 9

3.3.7 Front connector .................................................................................................................................. 9

3.3.8 LED.......................................................................................................................................................10

3.3.9 Backup battery ..................................................................................................................................10

3.3.10 GNSS configuration .........................................................................................................................11

4Setting up.............................................................................................................................................. 12

4.1 Test vehicle preparation..........................................................................................................................12

4.1.1 Wiring harness of the Head Unit ...................................................................................................12

4.1.2 OBD-II to VSS converter ..................................................................................................................13

4.1.3 Wheel speed sensor .........................................................................................................................13

4.2 EVK-M8L installation ...............................................................................................................................13

4.2.1 Mounting the GNSS antenna .........................................................................................................13

4.2.2 Mounting the EVK-M8L ..................................................................................................................13

4.2.3 Connecting the cables .....................................................................................................................14

4.3 Recommended configuration .................................................................................................................15

4.3.1 Serial port default configuration ...................................................................................................15

4.3.2 ADR configuration ............................................................................................................................15

4.4 Configuration and calibration drive.......................................................................................................18

5Test drives ............................................................................................................................................ 21

6Measuring tracking current ............................................................................................................ 22

7Block diagram ..................................................................................................................................... 23

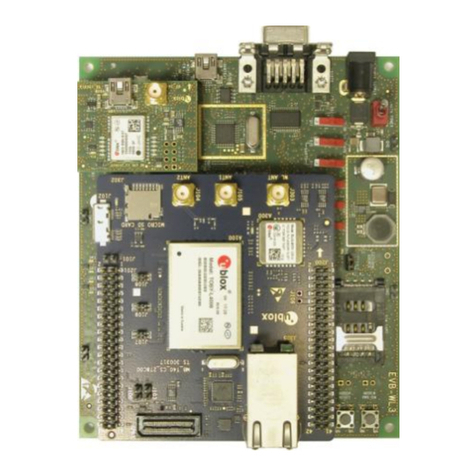

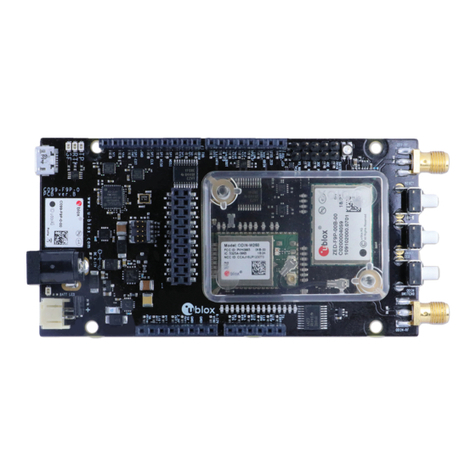

8Board layout.......................................................................................................................................... 24