4

►Details of Other settings menu.........................................................................................................23

♦Probe calibration............................................................................................................................................. 23

♦IT connection................................................................................................................................................... 23

♦Connectivity..................................................................................................................................................... 23

►Details of Use menu...........................................................................................................................24

♦Hot water & steam........................................................................................................................................... 24

♦Dosamat ...........................................................................................................................................................24

♦Infusion proles...............................................................................................................................................24

♦Standard mode..................................................................................................................................................24

♦Expert mode......................................................................................................................................................25

⌂MAINTENANCE & REPAIRS...................................................................................................27

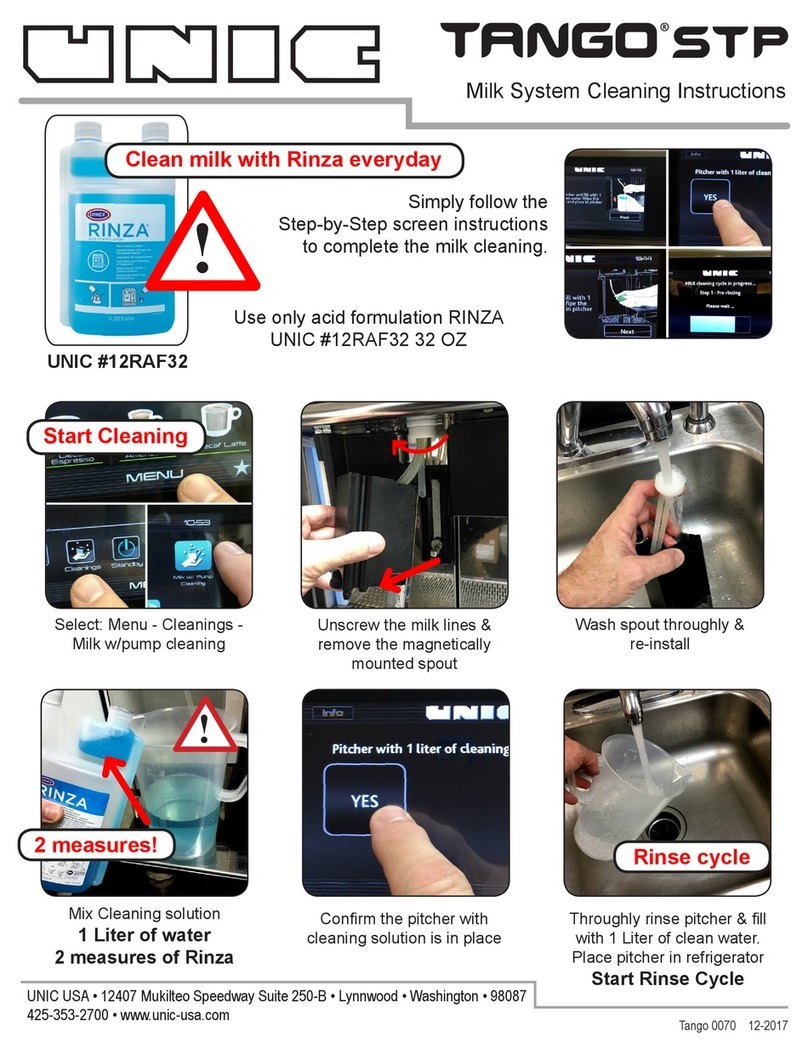

►Cleaning..............................................................................................................................................27

♦After each use..................................................................................................................................................27

♦Steam outlet tube ..............................................................................................................................................27

♦Daily.................................................................................................................................................................. 27

♦Before use or after several hours of inactivity: .................................................................................................. 27

♦After the service.................................................................................................................................................27

♦Weekly.............................................................................................................................................................. 27

♦Filter holder cup.................................................................................................................................................27

♦Basin..................................................................................................................................................................27

♦Bodywork...........................................................................................................................................................27

► Details of the coee cleaning Procedure menu ..............................................................................28

♦Coee rinsing ..................................................................................................................................................28

♦Coee cleaning................................................................................................................................................ 28

♦Reference of cleaning products.........................................................................................................................28

♦option SteamAir.............................................................................................................................................. 29

♦Components......................................................................................................................................................29

♦key SteamAir .................................................................................................................................................... 29

♦Programming.....................................................................................................................................................29

►Details of the Maintenance menu .....................................................................................................30

♦Components test............................................................................................................................................. 30

♦Softener............................................................................................................................................................ 30

♦Descaling..........................................................................................................................................................30

♦Machine cooling ..............................................................................................................................................31

♦Error log ...........................................................................................................................................................31

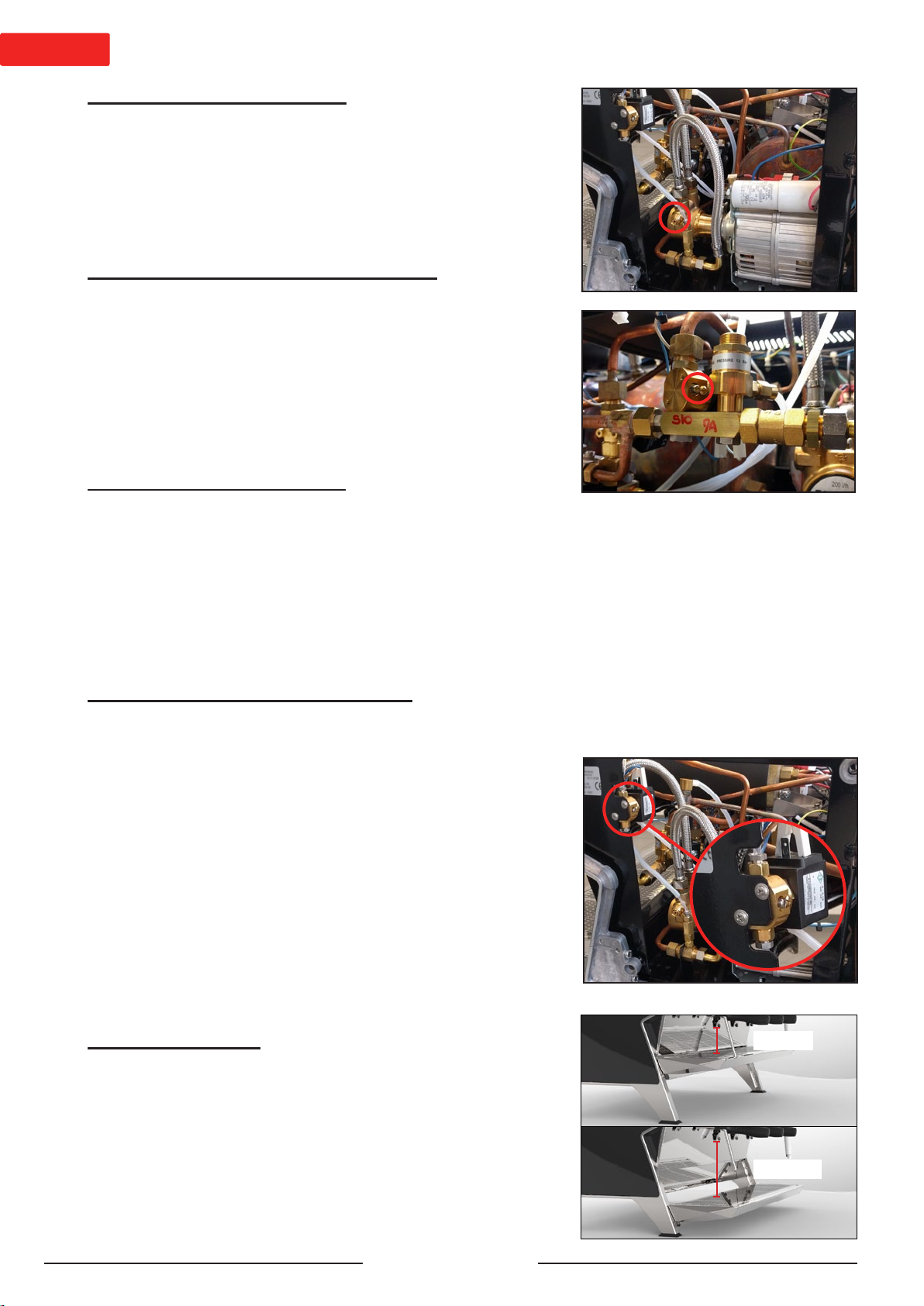

►Repairs ...............................................................................................................................................32

♦Troubleshooting.............................................................................................................................................. 32

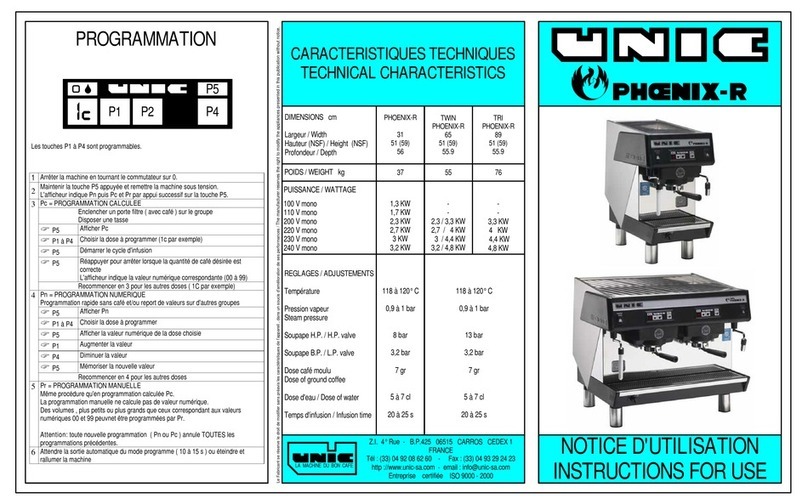

♦Technical features...........................................................................................................................................32

♦CPU connectors & fuses.................................................................................................................................33

♦Cable lists.........................................................................................................................................................34

♦Plate assembly.................................................................................................................................................36

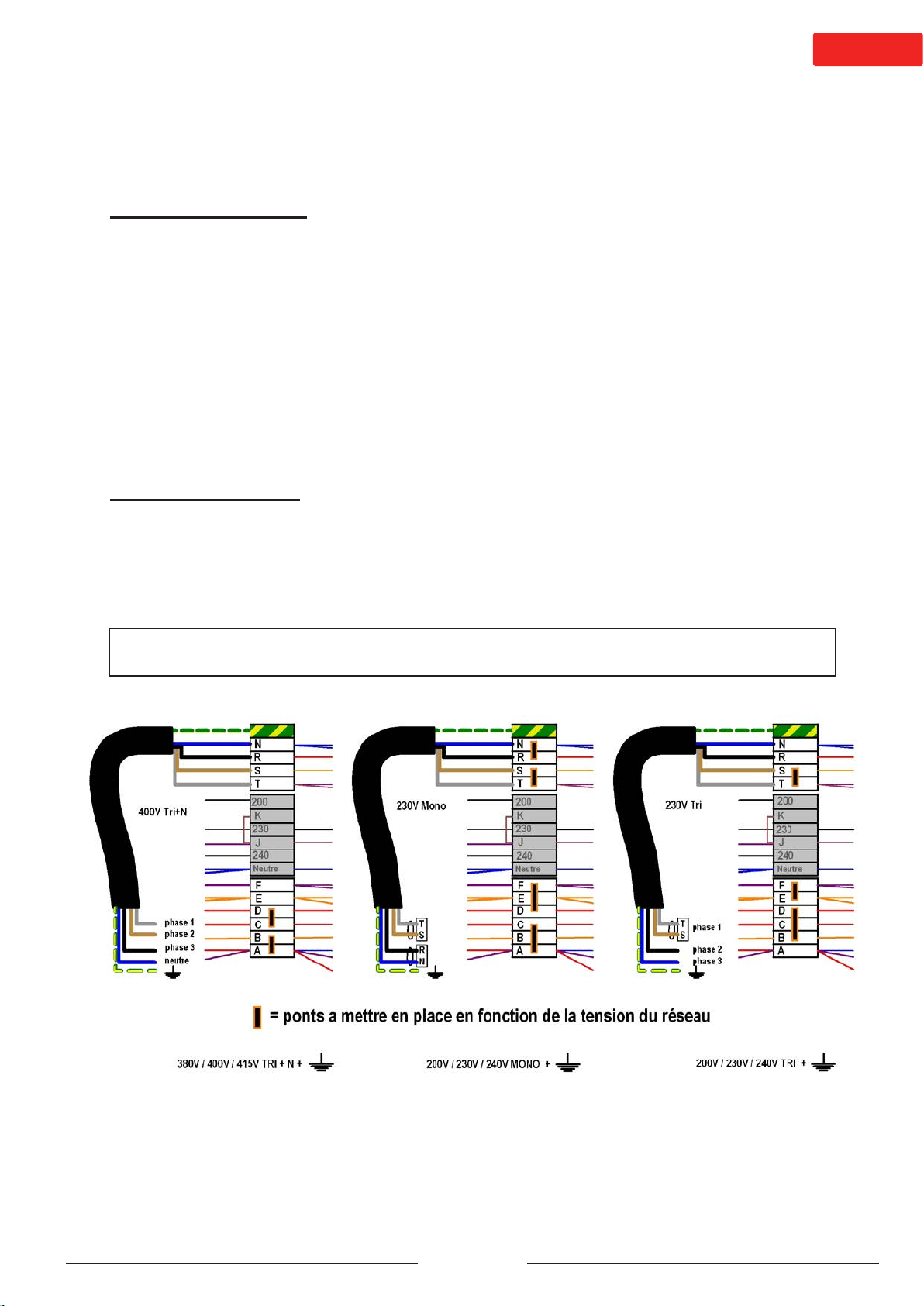

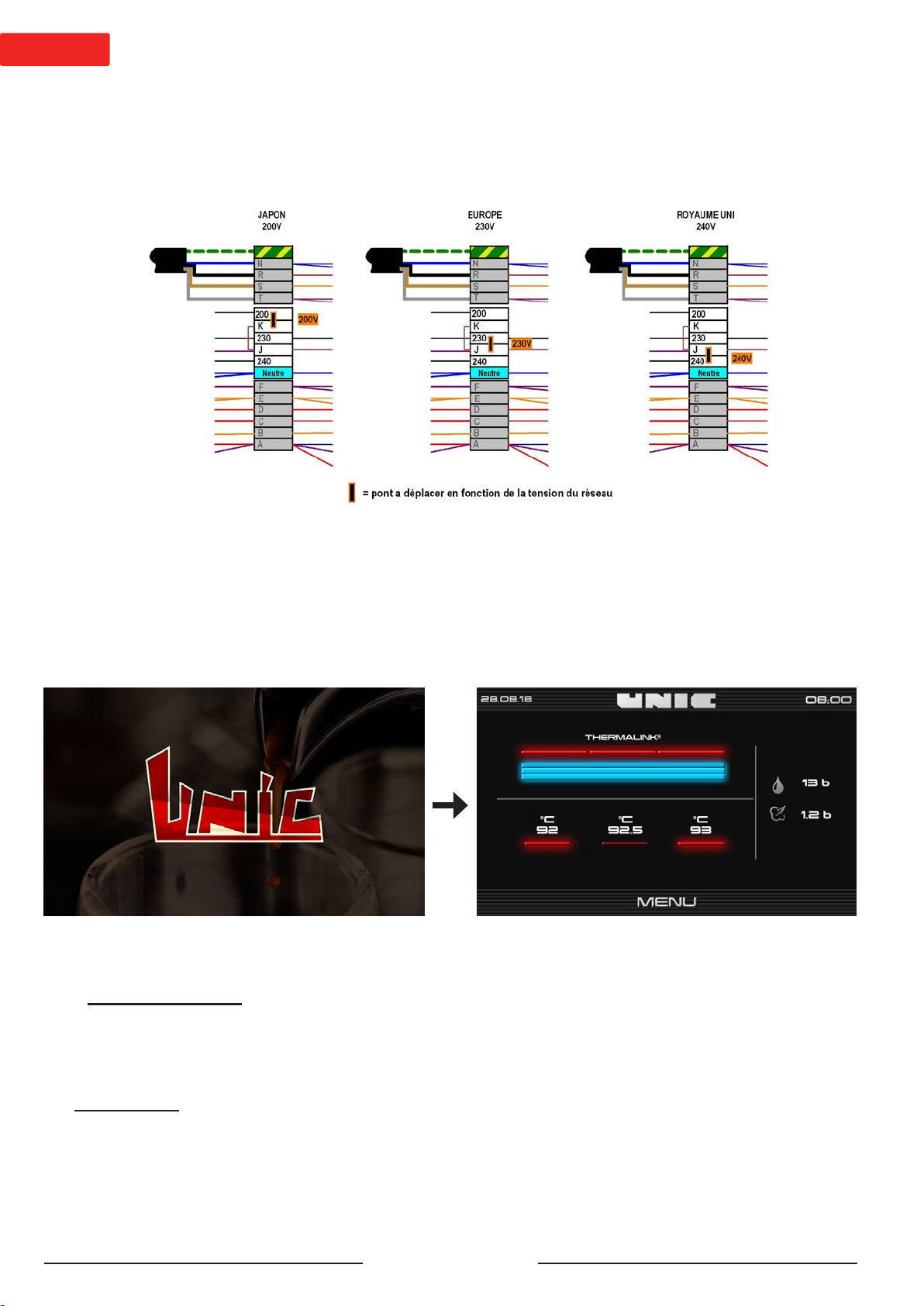

♦Wiring diagrams .............................................................................................................................................. 37

♦Procedure for updating the machine.............................................................................................................40

♦Assembly/replacement procedures...............................................................................................................42

♦Mother board replacement (CPU) .....................................................................................................................42

♦BTA/BGX/BST box replacement........................................................................................................................42

♦Cup seal............................................................................................................................................................43

♦List of error codes........................................................................................................................................... 44