4

►Grinder calibration.............................................................................................................................27

►Computer connection........................................................................................................................28

►Connectivity........................................................................................................................................28

►Keyboard Menu creation ...................................................................................................................29

►Hot water & steam..............................................................................................................................29

► ‘PS’ Specic program ........................................................................................................................29

►‘PP’ Programmed parameters...........................................................................................................30

►Product management ........................................................................................................................30

♦Adding a drink...................................................................................................................................................30

7-CLEANING & MAINTENANCE.................................................................................................31

►Cleaning external outlets / housing .................................................................................................31

♦ Coee outlet......................................................................................................................................................31

♦Cappuccino outlet .............................................................................................................................................31

♦Steam wand......................................................................................................................................................31

♦Drip tray.............................................................................................................................................................31

♦Housing.............................................................................................................................................................31

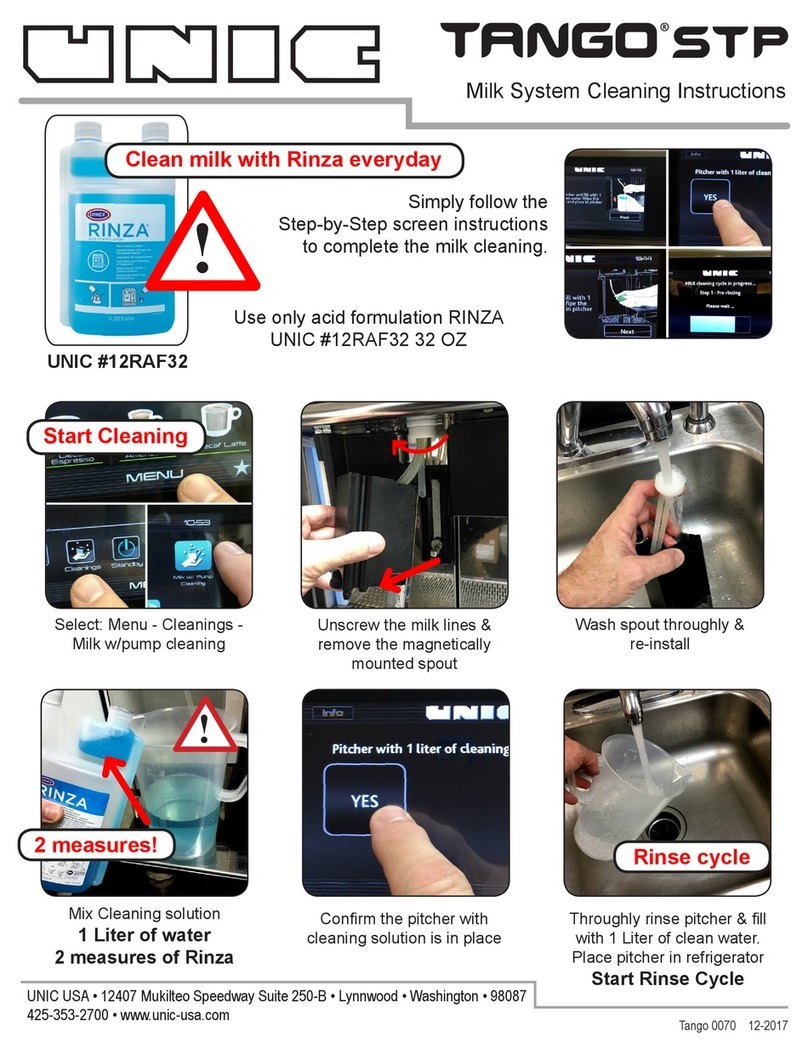

►Cleaning Cycles .................................................................................................................................32

♦ Milk & coee cleaning .......................................................................................................................................32

♦ Coee cleaning .................................................................................................................................................32

♦Cappuccino cleaning (with LC) .........................................................................................................................33

♦Powder cleaning (ACE MT)...............................................................................................................................34

8-MAINTENANCE & TROUBLESHOOTING ..............................................................................35

►Description of cycles.........................................................................................................................35

♦1 group Cycles..................................................................................................................................................35

♦Cappuccino Cycle.............................................................................................................................................37

♦Hydraulic circuit ACE MT...................................................................................................................................38

►Component test..................................................................................................................................39

►Cooling machine ................................................................................................................................40

►History of errors.................................................................................................................................40

►Softener...............................................................................................................................................40

►Descaling ............................................................................................................................................40

►How to ugrade CPU and Display ......................................................................................................41

►Lists of cables ....................................................................................................................................44

♦Static relays.......................................................................................................................................................45

♦Connectors........................................................................................................................................................46

♦Fuses ................................................................................................................................................................48

►Electronic Cards ................................................................................................................................50

♦Turntable set .....................................................................................................................................................50

► LED Identication on card.................................................................................................................51

►Active components............................................................................................................................54

►List of error codes..............................................................................................................................56

►Electric wirings...................................................................................................................................58

♦Electric wirings 5/12V........................................................................................................................................60

♦Electric wiring 24V.............................................................................................................................................61

►Front panel replacement ...................................................................................................................62