3

10.CLEANING AND MAINTENANCE………………………………………………………………….16

After each use...................................................................................................................... 16

Steam outlet tube: ............................................................................................................16

Daily..................................................................................................................................... 16

Before service or after several hours of inactivity:............................................................ 16

After service:..................................................................................................................... 16

Weekly ................................................................................................................................. 17

Cleaning with detergent tablet (automatic cycle).............................................................. 17

Filter holder....................................................................................................................... 18

Overflow tray: ................................................................................................................... 18

Body: ................................................................................................................................ 18

Water Softener..................................................................................................................... 19

Water Softener Regeneration: how?................................................................................ 19

Water Softener Regeneration: when?.............................................................................. 20

11.CONNECTION TO A COMPUTER SYSTEM……………………………………………………...21

Generalities.......................................................................................................................... 21

Machine preparation ............................................................................................................ 21

12.DISPLAYED FAILURES……………………………………………………………………………..23

Problems in connection with the electronic boxes’ control button........................................ 24

Fuse problems ..................................................................................................................... 24

Dosage problems................................................................................................................. 25

105-second safety system of the coffee unit.................................................................... 25

Metering safety system..................................................................................................... 26

Dosing device safety system............................................................................................ 27

13.OTHER FAILURES………………………………………………………………………………….. 28

Hydraulic problems of the coffee unit................................................................................... 28

Doses lighter than initially set........................................................................................... 28

Dripping outside infusion periods ..................................................................................... 28

An insufficient infusion pressure....................................................................................... 29

A wrong decompression process ..................................................................................... 29

Problems in connections with the level regulation ............................................................... 30

The steam boiler is flooded .............................................................................................. 30

The boiler is empty........................................................................................................... 30

Insufficient or no heating process ........................................................................................ 31

Impossible programing......................................................................................................... 31

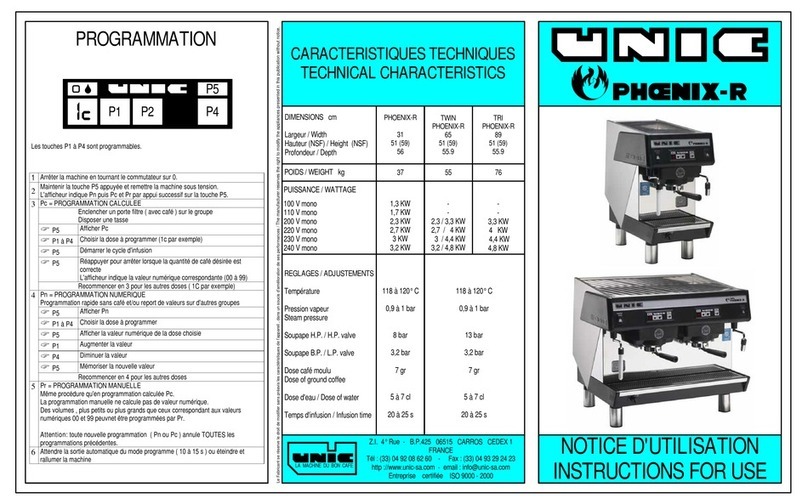

14.TECHNICAL CHARACTERISTICS…………………………………………………………………32