6

Contents

A SAFETY INFORMATION.........................................................................................................................7

A.1 General information ......................................................................................................................7

A.2 General safety .............................................................................................................................7

A.3 Personal protection equipment ........................................................................................................ 8

A.4 Transport, handling and storage ......................................................................................................8

A.5 Installation and assembly ...............................................................................................................9

A.6 Water connection..........................................................................................................................9

A.7 Electrical connection .....................................................................................................................9

A.8 Use ......................................................................................................................................... 10

A.9 appliance cleaning and maintenance .............................................................................................. 10

A.10 Service..................................................................................................................................... 10

A.11 Disposal of packing..................................................................................................................... 10

A.12 Machine disposal........................................................................................................................ 11

B GENERAL SAFETY RULES................................................................................................................... 11

B.1 Introduction ............................................................................................................................... 11

B.2 Mechanical safety characteristics, hazards....................................................................................... 11

B.3 Protection devices installed on the machine ..................................................................................... 11

B.4 Main switch ............................................................................................................................... 11

B.4.1 Appliance with 2 positions main switch................................................................................... 11

B.5 Safety signs to be placed on the machine or near its area.................................................................... 11

B.6 Instructions for use and maintenance.............................................................................................. 11

B.7 Reasonably foreseeable improper use ............................................................................................ 11

B.8 End of use ................................................................................................................................ 12

B.9 Residual risks ............................................................................................................................ 12

C GENERAL INFORMATION .................................................................................................................... 12

C.1 Introduction ............................................................................................................................... 12

C.2 Definitions................................................................................................................................. 12

C.3 Machine and manufacturer's identification data ................................................................................. 13

C.4 Additional indications................................................................................................................... 13

C.5 Responsibility ............................................................................................................................ 13

C.6 Copyright.................................................................................................................................. 13

C.7 Keeping the manual .................................................................................................................... 13

C.8 Recipients of the manual .............................................................................................................. 13

D NORMAL USE .................................................................................................................................... 14

D.1 Characteristics of personnel enabled to operate on the machine ........................................................... 14

D.2 Characteristics of personnel trained for normal machine use ................................................................ 14

D.3 Operator qualified for normal machine use ....................................................................................... 14

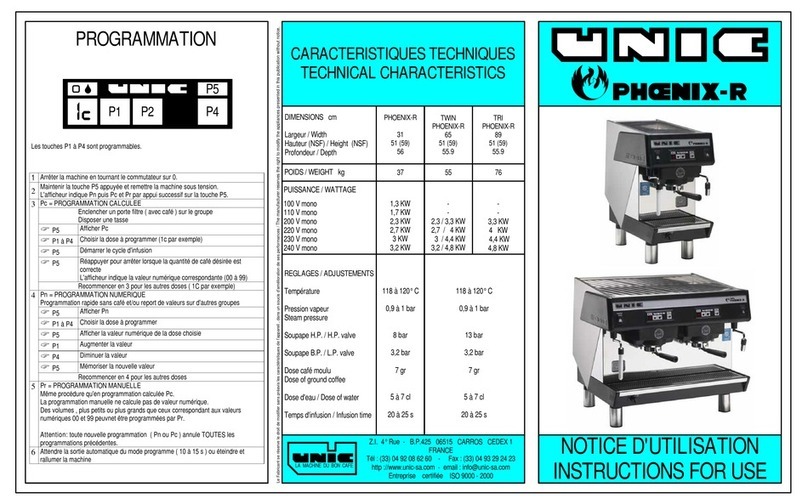

E TECHNICAL CHARACTERISTICS .......................................................................................................... 14

E.1 Data table ................................................................................................................................. 14

F OPERATING....................................................................................................................................... 14

F.1 Switching on.............................................................................................................................. 14

F.1.1 Filling the boilers............................................................................................................... 14

F.1.2 Switching on the heating .................................................................................................... 15

F.2 BTA description.......................................................................................................................... 15

F.2.1 Screen : thermal informations .............................................................................................. 15

F.2.2 Screen : Quick access / code............................................................................................... 15

F.2.3 Various icons ................................................................................................................... 15

F.3 Keyboards ................................................................................................................................ 15

F.3.1 Coffee keyboards.............................................................................................................. 15

F.3.2 Service keyboards............................................................................................................. 16

F.4 How to prepare a cappuccino ........................................................................................................ 16

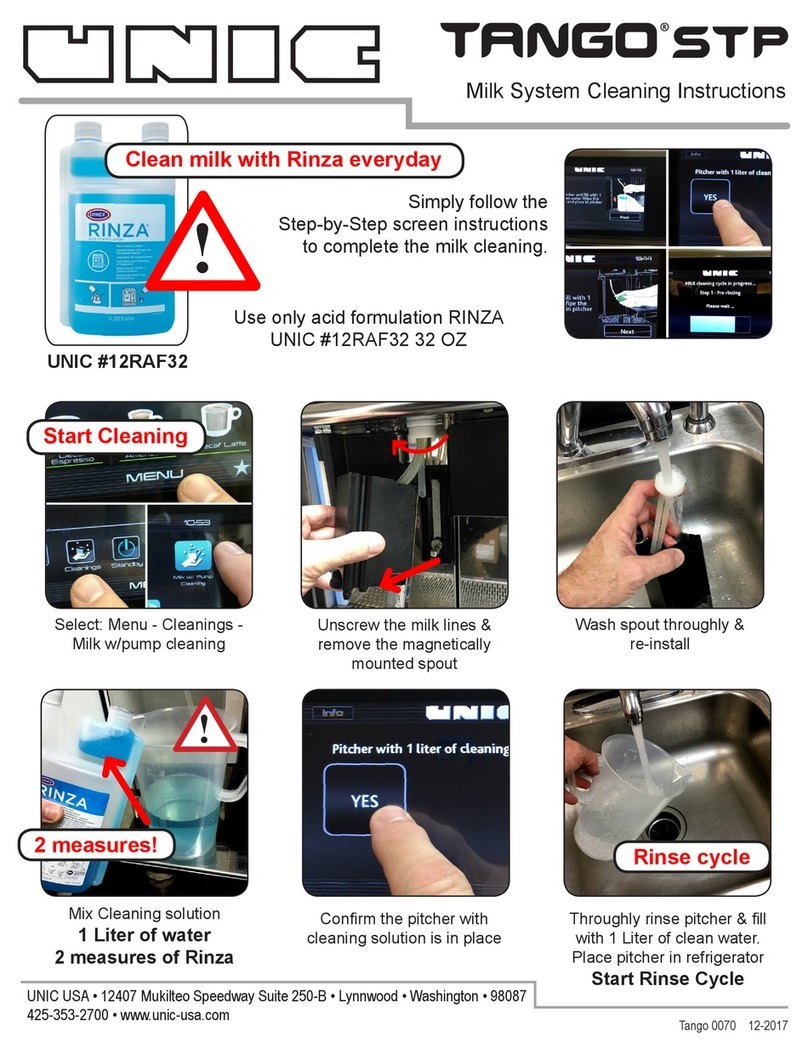

G DAILY CLEANING................................................................................................................................ 16

G.1 Cleaning groups......................................................................................................................... 16

G.1.1 Before use or after several hours of inactivity .......................................................................... 16

G.1.2 Rinse the decompression circuit ........................................................................................... 16

G.1.3 Semi automatic cleaning..................................................................................................... 16

G.2 External cleaning........................................................................................................................ 17

H MAINTENANCE .................................................................................................................................. 17

H.1 Maintenance intervals.................................................................................................................. 17

H.1.1 Preventive Maintenance ..................................................................................................... 17

H.2 Softener ................................................................................................................................... 17

H.3 Machine disposal........................................................................................................................ 17

I STEAMAIR OPTION............................................................................................................................. 18

I.1 Introduction ............................................................................................................................... 18

I.2 Components.............................................................................................................................. 18

I.3 Use ......................................................................................................................................... 18

I.3.1 Automatic mode (To reach the programmed T℃) ..................................................................... 18

I.3.2 Manual mode (Over the programmed T℃).............................................................................. 18

I.4 Programming............................................................................................................................. 18