- 9 -

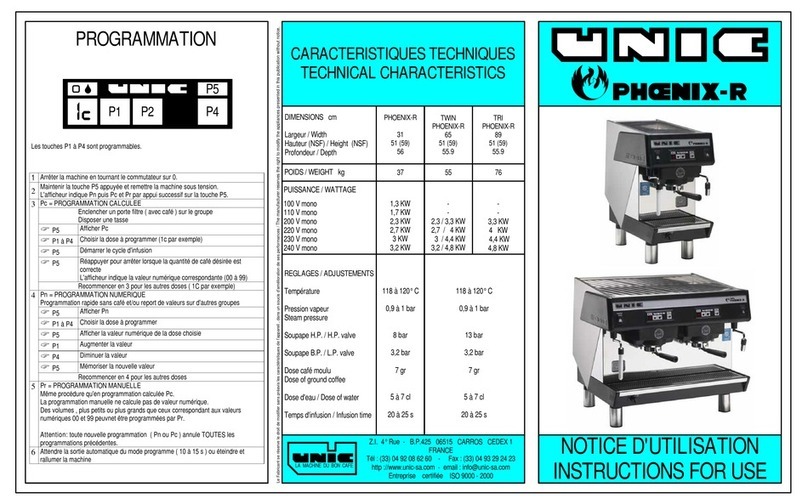

6.2 3 CUPS ELECTRONIC BOXES (type d3)

PRO

6.2a USE OF THE DOSES TO BE PROGRAMED

−6 coffee doses and 1 manual function, Continu/Stop are available. During the infusion, it is displayed :

* 1c, 2c ou 3c = 1, 2 or 3 small cups

* 1C, 2C or 3C= 1, 2 or 3 large cups

* C- = Continu/Stop

−At any time you can change the selection by pressing another key.

−The dosage is automatic but the infusion can be stopped manually by pressing the key Continu/Stop.

−Programing: The multiple doses being computed, only two programings are necessary (1c, 2c or 3c)

and (1C, 2C or 3C). If it is necessary, the "Continu" dose can also be programed.

6.2b CONFIGURATION PARAMETERS

* dn / dt For the automatic calculation of the multiple doses

dn = normal dosage

dt = dosage with "Torino" kit

* C0 / C1 Chronometer for the infusion time

C0 = no chronometer

C1 = display of the infusion time

* A0 / A1 Authorization to program

A0 = prohibited programing

A1 = authorized programing

* cc/cC/CC Start of infusion in small or large cup

cc = always starts in small cups

CC = always starts in large cups

cC = keep the last selection : c or C

After switching on, the display shows the following information in order:

−The version number of the electronic memory: ex. r1

−The type of box: d3

−The active functioning parameters: ex. dn, CO, A1, CC

6.2c MODIFICATIONS OF THE CONFIGURATION PARAMETERS

−Switch the machine off (switcher 0/1)

−Press simultaneously both keys P1 and P4, and in the same time, switch again the machine on

−Press the key P4 to change the selection (ex. dn or dt)

−Press the key P5 to change function (ex. dosage dn/dt or Chrono: C0/C1)

−Switch off to leave the configuration mode or wait the automatic leaving at the end of 10s.

Continu / Stop key