4USSC

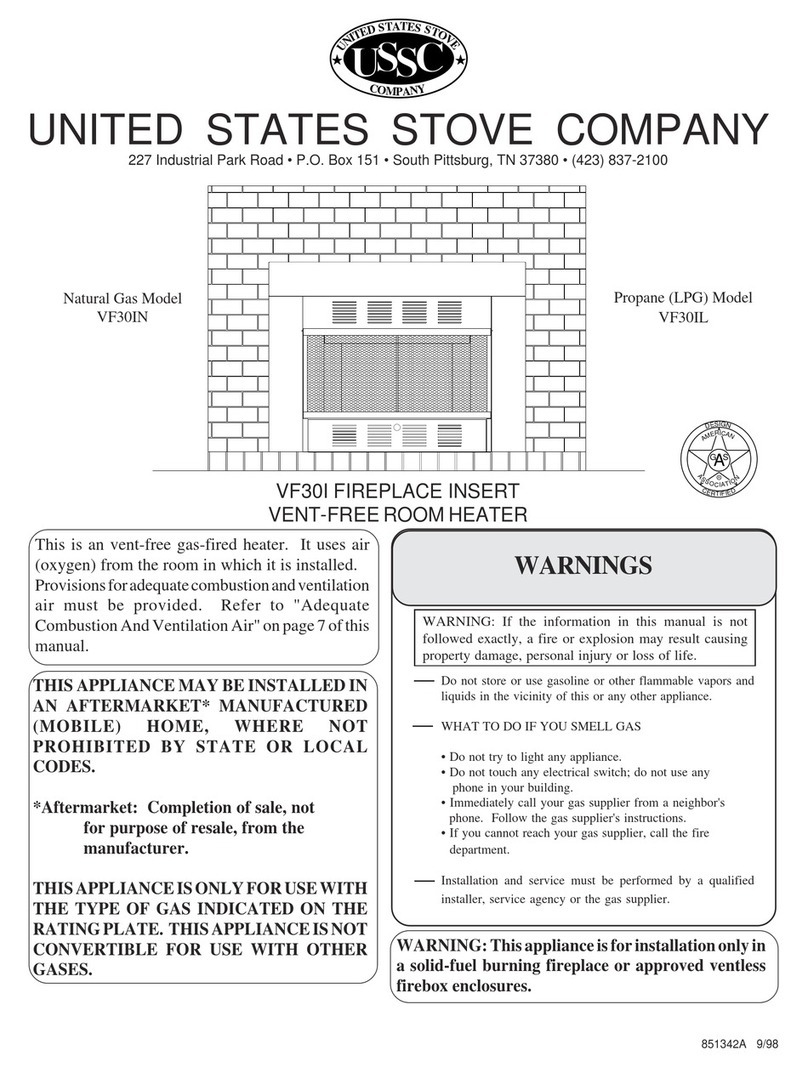

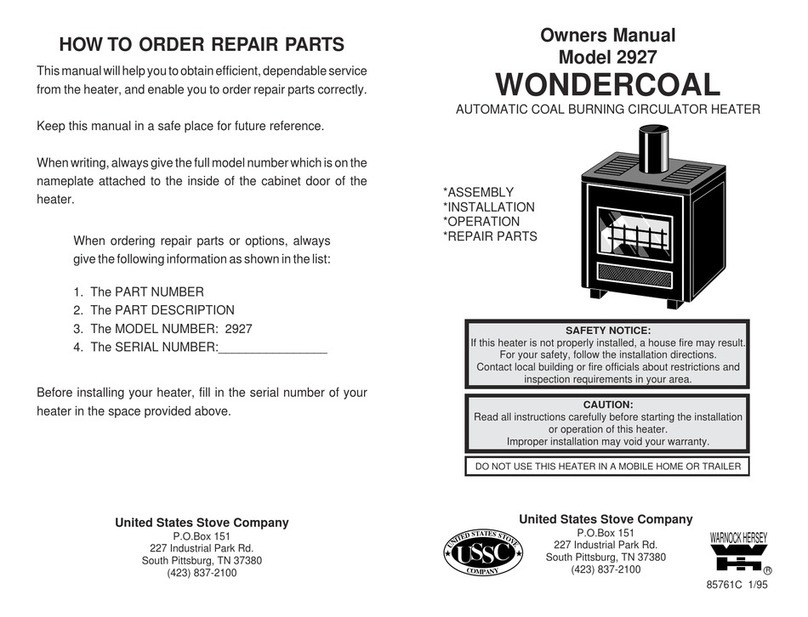

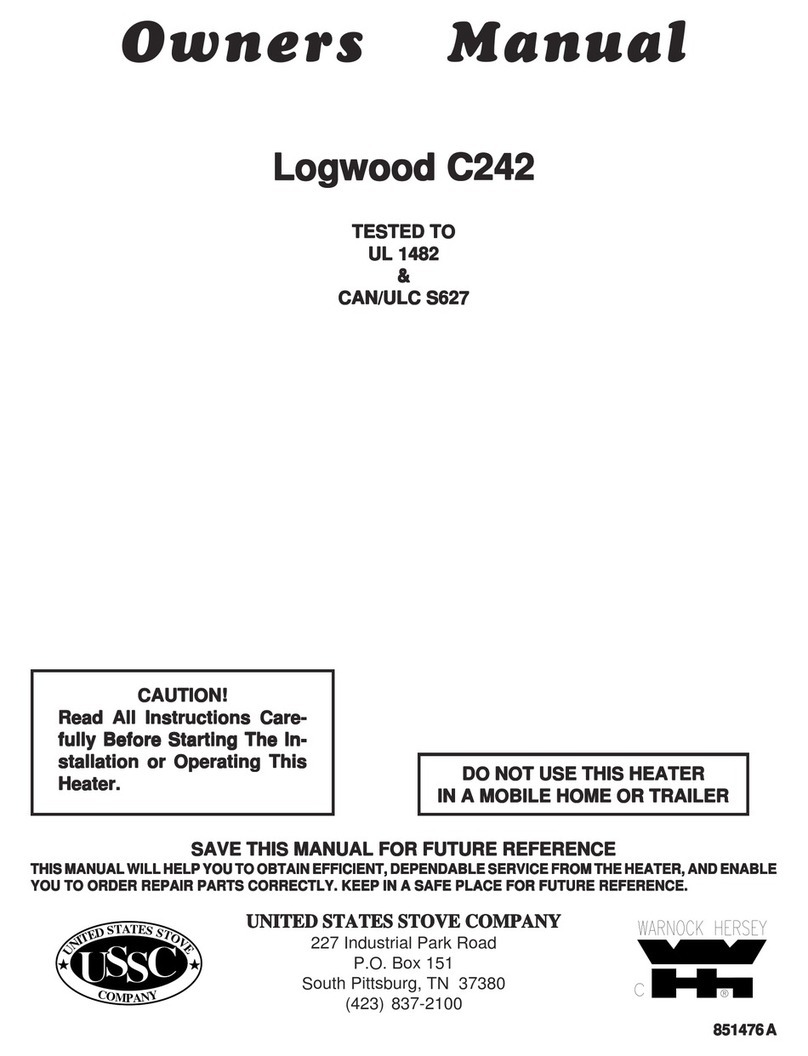

FIGURE 1 -

MASONRYCHIMNEY

REQUIREMENTS

FLUE

MINIMUM 1/2" AIR SPACE

FOUNDATION

CHIMNEY WALL 4"

NOMINAL

5/8" FIRECLAY OR

STAINLESS STEAL

FLUE LINER

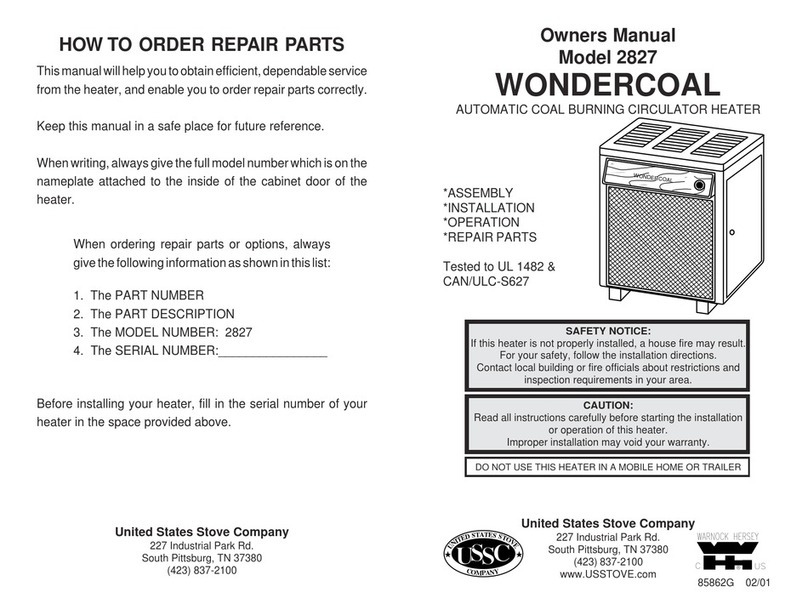

If the heater is to be connected to a masonry chimney, the heater should not be installed until it is determined that the

chimneyissafeforuse. Beforeinstalling the heater, havethechimneyinspectedbyabuilding inspector, fire department,

orqualifiedheatingengineer. Toprevent risk of walls,roof,orothercombustibles catching fire fromtheextremelyhotfire,

smoke,andfluegases,andtoobtain a proper draw, a chimneymustmeettheminimumstandardsfor masonry chimneys

establishedbytheNational Fire Protection Association(NFPA). Makecertaintheinspection agency isfamiliarwithNFPA

No. 211 and all local codes. Some of those minimum standards are listed here for your convenience.

1. The chimney must not be obstructed or clogged. An obstructed or clogged chimney could cause smoke and the

dangerous carbon monoxide in smoke to spill back into your home.

2. Your masonry chimney must be supported on an adequate foundation and must have either a 5/8" thick fireclay or

stainlesssteellining. Theremust beatleast1/2-inch air spacebetweentheflue liner andthechimneywall. (See Figure1.)

3. A chimney inside the house must have at least 2 inches of clearance to the combustible structure. A chimney outside

the house must have at least 1 inch clearance to the combustible structure. Fire stops must be installed at the spaces

where the chimney passes through floors and/or ceilings. (See Figure 2.) Insulation should be at least 2 inches from the

chimney to leave an air space around the chimney. (See Figure 3.)

4. The flue lining of a masonry chimney must be smooth and

havenoleaks. Theinsideofthe chimney flue liner should beno

smaller than 8 inches square or 6 inches round; a smaller chim-

ney flue liner will be too restrictive to the flow of smoke and

gases. A6inchdiameter round liner ispreferredbecauseround

flues draw better than square flues.

5. Since an oversized chimney flue contributes to the accumu-

lation of creosote, the size of the chimney flue liner must be

checked to determine that it is not too large for the heater. For

thisheater,the insidecross-sectionalareaofthechimneyshould

be no more than 85 square inches to assure proper venting.

6. The top of the chimney must be at least 3 feet above the

point where it comes through the roof, and at least 2 feet higher

than any obstruction within a 10 foot radius.(See Figure 4.)

7. If the heater has insufficient draft, the draft may be improved

by extending the height of the chimney.

8. Make certain the chimney is kept clean and it is not blocked.

Checkforlimbsoverhanging the top ofthechimneyperiodically.

MASONRY CHIMNEY REQUIREMENTS

1. When locating the heater , consider safety, convenience, traffic flow, and the fact that the heater will need a

chimney,chimneyconnector,and possibly a floor protector. Make sure none of these materials will be obstructed.

2. The heater should be located away from door ways and central heat outlets to reduce the chances of drafts, blowing

smoke, ashes or sparks out of the heater during refueling or ash removal.

3. The heater should be located in an open area to allow for necessary clearances as specified within this manual.

4. Keepfurniture,drapes,curtains,wood, paper and other combustiblesfarawayfromtheheater.

5. Never install the heater in locations where gasoline, kerosene, charcoal lighter, or any other flammable liquids are

stored

6. Theheatershouldbe locatedwhereasmallsupply of woodmaybekept conveniently closebutnotwithin 36-inches of

theheater.

7. Theheatershould notbelocatedbeneath overhangingshelves,lowceilings orotherstructuresor elevatedsothatless

clearance is created above the heater than is provided when the heater is normally installed in a room with a 7 foot

minimumceiling.

8. Be sure the chimney will be at least 10 feet from flammable gas or liquid storage tanks.

DANGER: DO NOT CONNECT THIS HEATER TO A CHIMNEY FLUE SERVING ANOTHER APPLIANCE. THERE IS A

SERIOUS SAFETY RISK IF TWO APPLIANCES ARE CONNECTED TO THE SAME CHIMNEY FLUE.

CAUTION: Theoperationofexhuastfanssuchasbathroomfans,atticfans,etc.mightstarvetheheaterofcombustible

aircreatinganegativepressureinthe room. Provide adequate ventilation in theroomoccompaningtheheater.

SELECTING A LOCATION FOR YOUR HEATER