1.

2.

3.

4.

5.

6.

7.

8.

9.

18 3

RULES FOR SAFE INSTALLATION AND OPERATION

Read these rules and the instructions carefully.

SAFETY NOTICE: If this heater is not properly installed, a house fire may result. For your

safety, follow the installation directions. Contact local building or fire officials about

restrictions and installation inspection requirements in your area.

Check local codes. The installation must com-

ply with their rulings. Do not install this heater

in a mobile home or trailer.

Always connect this heater to a chimney or

vent to the outside. Never vent to another

room or inside a building.

Do not connect a COAL burning heater to an

aluminum Type B gas vent. This is not safe

and is prohibited by all codes. This heater

requires connection to approved chimneys:

Either a factor built 6" UL 103HT or a lined and

approved and recently inspected and cleaned

masonry chimney with a 6" flue, preferably

round. A larger masonry flue may be used, so

long as the flue-section diameter is not greater

than 50 sq. in.

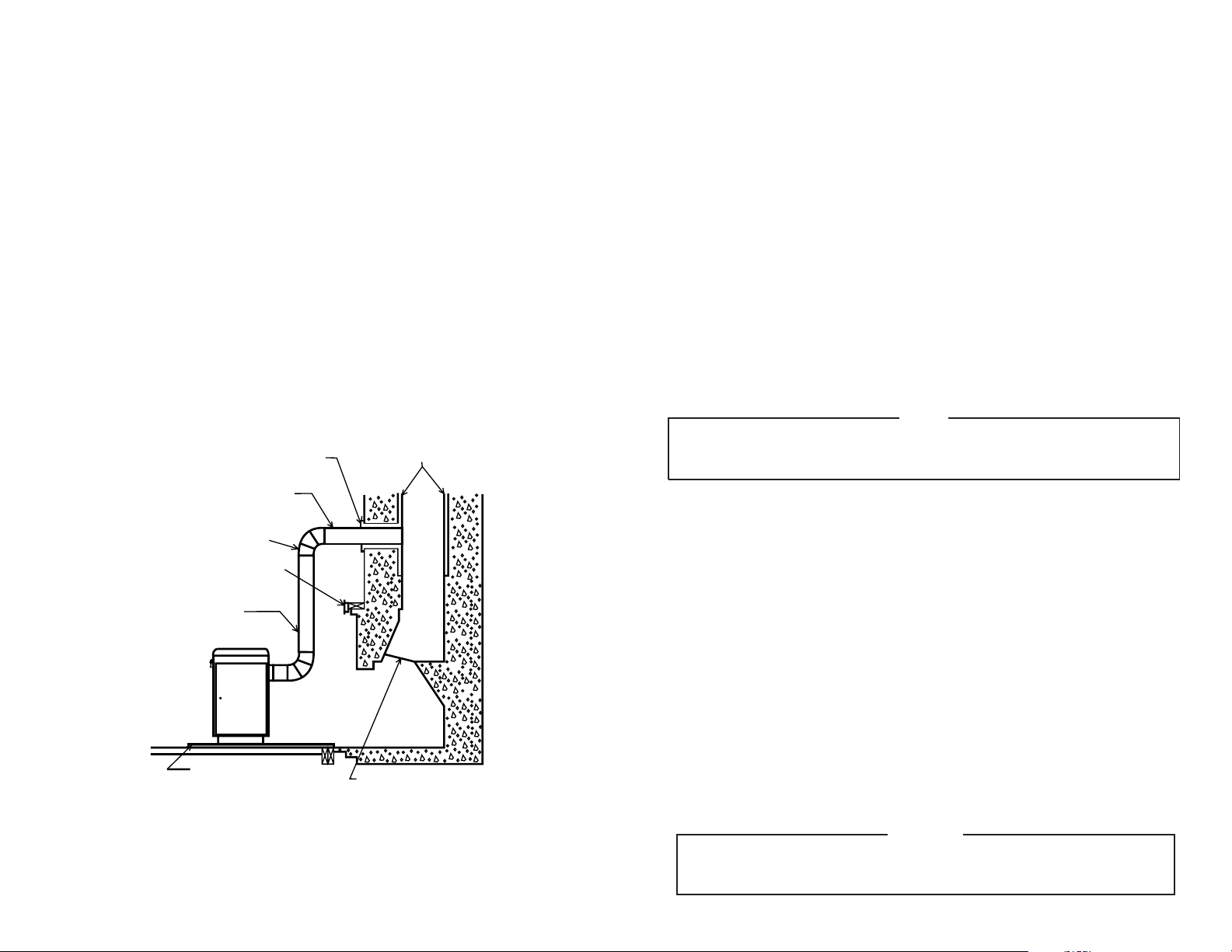

The chimney portion (whether factory-built or

masonry) must be tall enough to provide

sufficient draft and safe exit of smoke and

combustion products. Please refer to Page 5.

Be sure that your Chimney is safely con-

structed and in good repair. Have the chimney

inspected by the Fire Department or a quali-

fied inspector (such as a Chimney sweep).

Your insurance company may be able to

recommend a qualified inspector.

Inspect chimney connector and chimney twice

monthly during the heating season for any

deposit of creosote or soot which must be

removed.

Provide air for combustion from outside the

house into the room where the heater is

located. If the intake is not in the same room,

air must have free access to the room.

CAST IRON PARTS MUST BE "SEASONED"

TO AVOID CRACKING. BUILD ONLY SMALL

FIRES ON FIRST USE.

To prevent injury, do not allow anyone to use

this heater who is unfamiliar with the correct

operation of the heater. Do not allow children

to use or in any way operate this heater.

For further information on using your heater

safely, obtain a copy of the National Fire

Protection Association (NFPA) publication

"Using Coal and Wood Stoves Safely" NFPA

No. HS-10-1978. The address of the NFPA

is Battery March Park, Quincy, MA. 02269.

Keep the ash pit section free of excess

ashes. Do not allow ashes to stack higher

than the sides of the ash pan.

DISPOSAL OF ASHES- Ashes should be

placed in a metal container with a tight fitting

lid. Keep the closed container on a non-

combustible floor or on the ground, well away

from all combustible materials. Keep the

ashes in the closed container until all cinders

have thoroughly cooled. The ashes may be

buried in the ground or picked up by a refuse

collector.

CAUTION: The special paints used on your

heater may give off some smoke while they

are curing during first few fires. Build small

fires at first. The metals used in construction

of the heater has a light coating of oil. This

could give off smoke and/or odors when

heater is used for the first couple of times.

This should disappear after a short period of

time. Once this burn-off has occurred, it

should not reoccur.

CARING FOR PAINTED PARTS- This heater

has a painted outside jacket, which is durable

but it will not stand rough handling or abuse.

When installing your heater, use care in

handling. Clean with soap and warm water

when heater is not hot. DO NOT use any

harsh chemicals (acids or caustics) or scour-

ing powder, as these wear and dull the finish.

KEEP THE FEED DOOR, ASH DOOR AND

CABINET DOOR CLOSED AT ALL TIMES

EXCEPT WHILE TENDING THE HEATER.

DO NOT OVERFIRE THE HEATER. THIS

WILL HAPPEN IF THE FEED DOOR, OR

PARTICULARLY THE ASH DOOR, IS LEFT

OPEN DURING OPERATION. UNDER EX-

TREME CONDITIONS THIS CAN PRO-

DUCE DANGEROUS RESULTS. AS A MINI-

MUM, IT WILL ALLOW THE PAINT TO

DISCOLOR.

Use coal only. DO NOT USE the coal bricks

that are manufactured from coal dust and a

wax-type binder.

CAUTION: DO NOT TOUCH THE

HEATER UNTIL IT HAS COOLED.

ALWAYS WEAR GLOVES WHEN

REFUELING THIS UNIT OR WORKING

WITH METAL CABINET PARTS.

10.

11.

12.

13.

14.

15.

16.

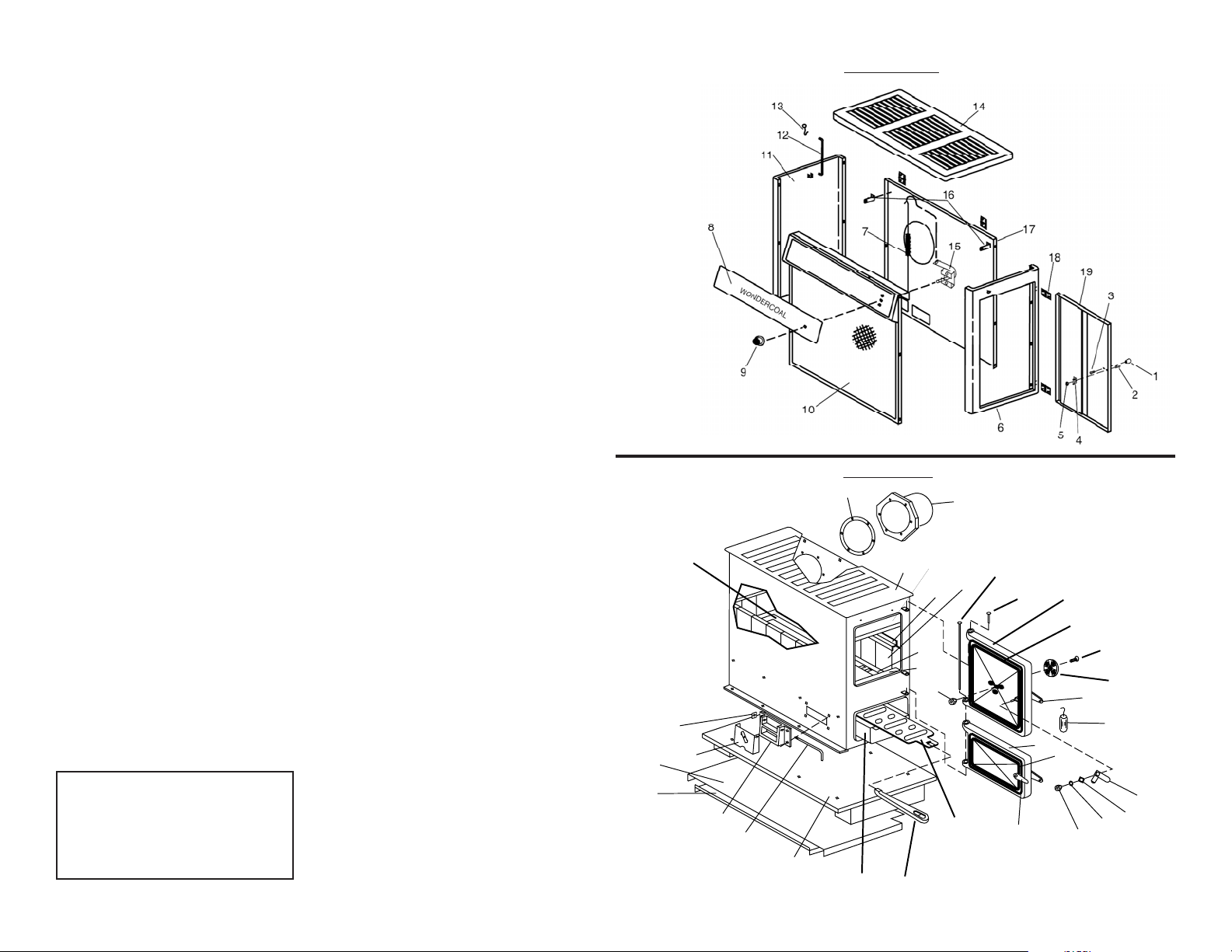

INTERIOR REPAIR PARTS LIST - (SEE PAGE 15)

AUTOMATIC COAL BURNING CIRCULATOR

Key No. Description Qty. Part No.

1 Shaker 1 40045

2 Second Heat Shield Assembly 1 22030

3 Heat Shield 1 22110

4 Draft Damper Hinge Pin 1 17200

5 Draft Damper Frame 1 40075

* 1/4-20 x 3/4 MS 4 83086

* 1/4-20 Kep Nut 4 83250

6 Base 1 67859

7 Draft Control Damper 1 67132

8 Clip 1 83818

9 Coal Grate 1 40101

10 Grate Support 2 22536

* 1/4-20 x 3/4 MS 8 83086

* Nut 1/4-20 Kep 8 83250

11 Firebrick 10 89066

12 Firebox 1 67858

13 Front & Back Liner 3 40100

14 Flue Collar 1 40246

15 Flue Collar Gasket 1 88032

16 Firebrick Retainer 2 40132

* 1/4-20 x 1 6 83227

* 1/4-20 Kep Nut 6 83250

* Smoke Curtain Bracket 2 22171

* 1/4-20 Kep Nut 2 83250

* Machine Screw (1/4-20 x 3/4 PH) 2 83086

17 Hinge Pin 1 83872

18 Smoke Curtain 1 22090

19 Coal Grate Frame 1 40102

20 Feed Door Assembly 1 69519

21 1/4-20 Kep Nut 2 83250

22 Draft Wheel 1 40056

23 Machine Screw (1/4-20 x 1) 1 83227

24 Door Handle 2 40091

25 Wood Handle 1 89523

26 Feed Door Rope Gasket 45" 88033

27 Ash Door Assembly 1 69520

28 Two-Step Latch 1 22434

29 Washer, Flat 2 83045

30 1/4-20 Kep Nut 2 83250

31 Ash Door Gasket 29" 88033

32 Latch 1 22108

33 Ash Pan 1 67444

* 1/4-20 x 3/4 MS, SL, FL,2 6 83086

* 1/4-20 Kep Nut 6 83250

34 Latch Spacer 1 21467

35 Hinge Pin (Long) 1 83114

* NOT SHOWN