8

Install the stovepipe as far as possible

into the thimble, but not past the inside

of the flue lining. There should be a

small air space (approximately 1/2 in.)

between the stovepipe and thimble, al-

lowing for expansion of the stovepipe.

Seal this airspace with high-tempera-

ture caulking or ceramic wool. Finally,

be sure to wire the damper closed and

apply the same sealant you used at the

stovepipe and thimble junction.

Do not vent up through the fireplace

opening,regardlessof whether the fire-

place opening is closed.

MASONRY CHIMNEY have several

positiveattributes: If properly built, they

arequitedurable,andmosthomeowners

consider them more attractive perhaps

than a non-enclosed factory built

chimney. And,ifthechimney is located

withintheconfinesof the house (that is,

not attached to an exterior wall), its

mass alone will store heat longer and

continue to release the heat long after

the fire has died. Masonry chimneys

have many disadvantages though.

Masonry chimneys constructed on an

exterior wall are exposed to cold out-

door temperatures, promoting greater

heater loss, higher accumulations of

creosote,andreduceddraftwhichleads

topoorerheaterorfurnaceperformance.

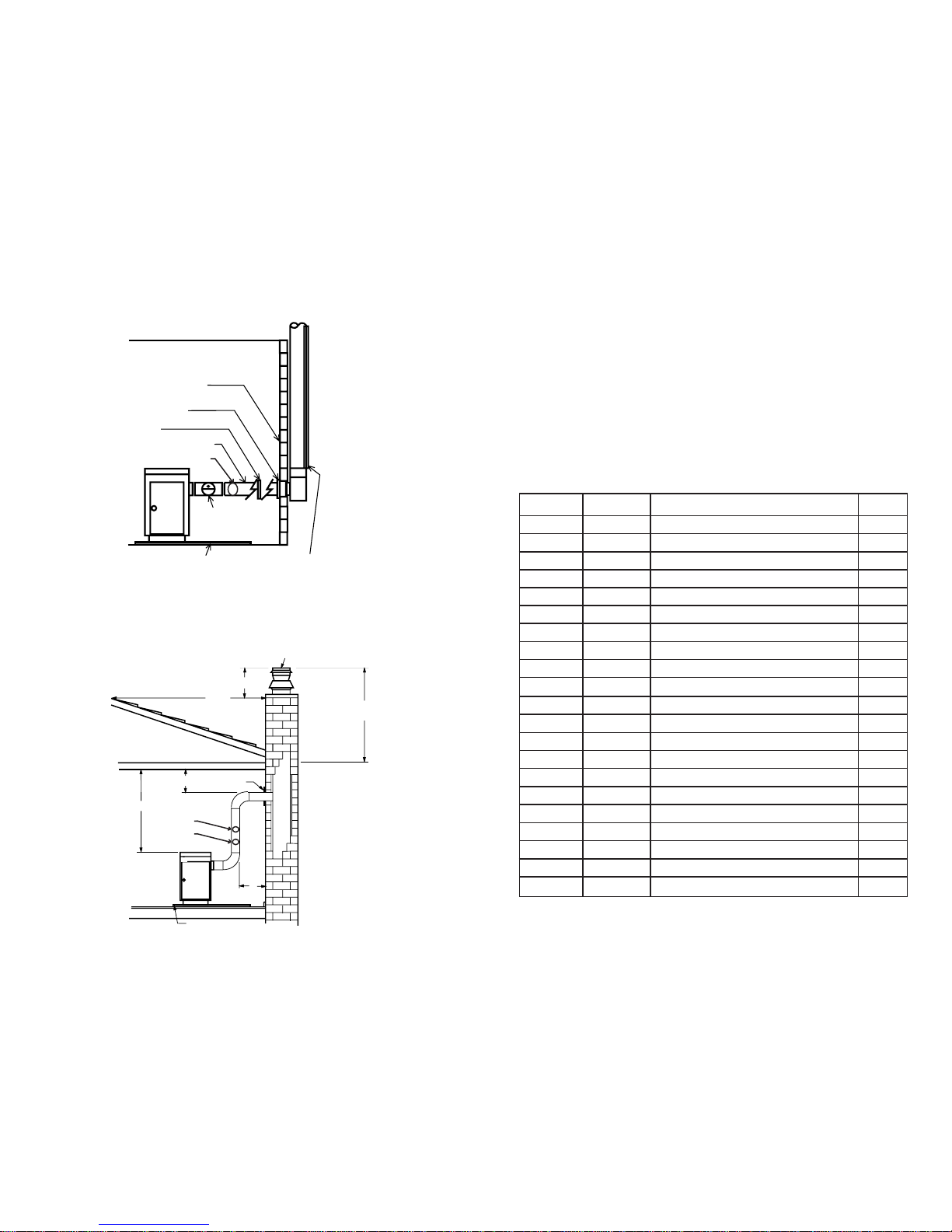

FIREPLACE INSTALLATION

Connectionofthestovepipedirectlyinto

the existing masonry chimney over the

fireplace opening is the only approved

method. This installation performs bet-

ter, yielding easy to clean and inspect

forcreosote.Before beginning this type

of installation plan carefully; a high de-

gree of skill is required to insure safety.

An entry port for the stovepipe must be

cut through the chimney with minimum

damage to the fire clay liner. Some

involvedmeasurementsmayberequired

to locate the flue liner exactly. Before

cutting, take time to mark the size and

position of the entry port. Position the

entryport so that at least 8 inches ofthe

flue liner remains below the port.

Keep in mind that wood mantels and

combustible trim around the fireplace

must have adequate clearances from

the heater and stovepipe or must be

protectedinanapprovedmanner.Also,

be sure to leave at least 24" clearance

between the top of the stovepipe and

the combustible ceiling or other com-

bustibles.Placingthecenteroftheentry

port 2 feet below the ceiling will insure

proper clearance for 6 inch, 8 inch, and

10 inch stovepipes. Next, install a fire

clay (at least 5/8 in. thick) or metal

thimble, being sure that the thimble is

flush with the inner flue lining. Secure

thethimbleinplacewithrefractorymor-

tar. The thimble should be surrounded

on all sides with 8 inches of brickwork

(solid masonry units) or 24 inches of

stone.

CAUTION

A chimney fire may cause ignition of wall studs or rafters which you

thought were safe distance from the chimney. If you have a chimney fire,

have your chimney inspected by a qualified person before using again.

Do not expect a heater to draw. It is the

chimney that creates the draft. Smoke

spillage into the house or excessive

build-up of water or creosote in the

chimneyare warnings that the chimney

is not functioning properly. Possible

causes are:

1. Theconnection pipe maybepushed

into the chimney too far, stopping the

draft (Fig. 8).

2. Two heaters connected into the

same chimney flue.

3. Samefluebeingusedtoventilatethe

cellarorbasement.Ifthereisacleanout

opening at the base of the chimney, it

must be closed tightly and sealed.

4. If the chimney is too cool, water will

condense in the chimney and run back

into the stove. Creosote formation will

be rapid and may block the chimney.

Operatetheheateratahighenoughfire

to keep the chimney warm preventing

this condensation. (Poorly insulated

chimney)

5. The chimney top may be lower than

another part of the house or a nearby

tree. The wind blowing over a house or

a tree falls on top of the chimney like

water over a dam, beating down the

smoke. The top of the chimney should

be at least 3 feet higher than any point

of the roof within 10 feet (Fig. 6).

6. Other chimney/flue inadequacies

covered else where in this manual.

If creosote has accumulated, it should

be removed.

Failure to remove creosote or soot may

cause a house fire. Creosote may be

removed by using a chimney brush or

othercommonlyavailablematerials. Or,

betteryet,byacertifiedchimneysweep.

Chimneyfiresburnveryhot.Ifthechim-

neyconnectorshouldglowred,immedi-

ately call the fire department, then re-

duce the fire by closing the inlet air

control and closing the damper in the

pipe.

CHIMNEY MAINTENANCE

CREOSOTE-FORMATION AND NEED FOR REMOVAL

NOTE:

A draft reading of .05 to .06 w.c. is suggested for proper burning of this

unit.

SERVICE HINTS

13

When wood is burned slowly, it pro-

duces tar and other organic vapors,

which combine with expelled moisture

to form creosote. The creosote vapors

condenseinthe relatively cool chimney

flue of a slow burning fire. As a result,

creosote residue accumulates on the

flue lining. When ignited, this creosote

makes an extremely hot fire.

The chimney connector and chimney

should be inspected at least twice

monthly during the heating season to

determine if a creosote build-up has

occurred.