OPERATING INSTRUC-

TIONS

FUEL

Eggsize Bituminous coal forresidential

furnaces, or any of the specially pack-

aged fireplaces coals can be used.

Coal with a low ash content (2% to 6%)

is recommended.

NOTE:Storecoalinadry,well-venti-

lated area.

LIGHTING

1. Set the thermostat on "High" for

maximum draft.

2. Open the feed door and place paper

andkindling on the grate for startingthe

fire.

3. Light fire and close feed door.

4. Add about 15 pounds of coal de-

pending on model after fire is burning

briskly. Use care not to smother the

kindlingfire.Sethigheror lowerforyour

comfort.

5. Set thermostat for desired tempera-

ture.

ADDING FUEL

Whenstartingafire,addsmallamounts

of fuel periodically as required (enough

toburnfor3to5hours).Asyou become

more familiar with the operation of your

heater, it is possible to add coal to burn

for longer durations of between 8 to 12

hours, but doing so carelessly will pro-

mote incomplete combustion and con-

siderable sitting, along with a very dirty

inefficient fire.

1. SetthermostattoHIGHbeforeopen-

ing feed door.

2. Coal Fire- Never smother the fire

when adding coal (see CAUTION be-

low). Gas accumulation and a mild

smoky explosion will occur:

a. Add fresh kindling if the bed of

coals has cooled.

b. Add up to 20 lbs. of coal. Never

add coal above top of the firebrick.

c. Stir the coal and watch the fire.

Be sure the new coal is burning

before you close the doors and turn

the thermostat down.

3. Shake Grates vigorously back and

forth to dump ashes into ash pan. Do

this at least once every 12 hours of

operation.

4. Empty ash pan regularly. Do not

allowashestobuilduptograte,asgrate

will warp and burn out, and you might

spill the ashes when removing the pan.

Dispose of hot ashes properly. (See

note 11 on page 3)

CAUTION: BUILD A FIRE ON INTE-

GRAL GRATE THAT IS PROVIDED

WITH THE HEATER.

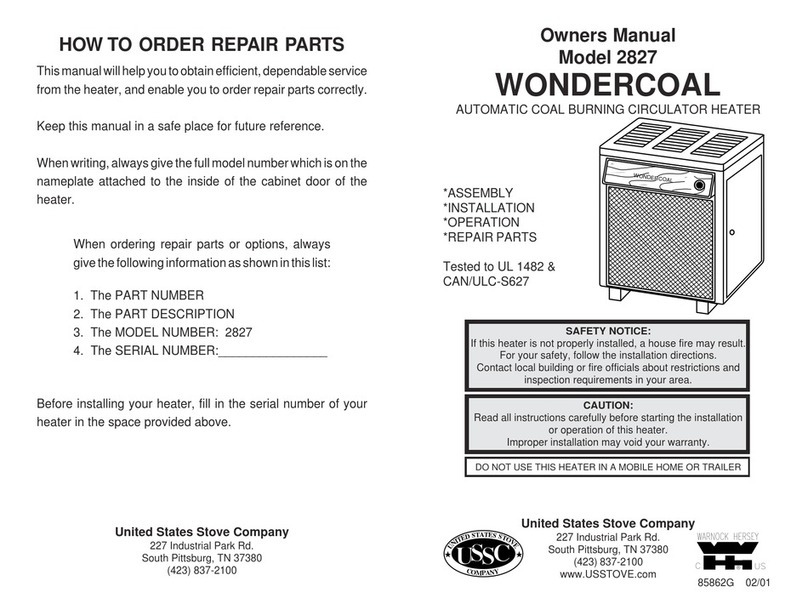

MINIMUM FIRE

The burning rate at the low setting can

be further adjusted by opening or clos-

ing the minimum fire air shutter (Fig. 9)

on the draft control door.

1. Partiallyclosetheshuttertomakethe

fuel burn longer.

2. Open the shutter, exposing a large

opening, to reduce the formation of

creosote on soot (see notes on Chim-

ney Maintenance).

3. Do not operate the heater with the

minimum fire air shutter completely

closed.

CAUTION: DO NOT OVERFIRE THE

HEATER,ASSTATEDEARLIER,THIS

CAN PRODUCE A DANGEROUS

CONDITION AND EVEN CAUSE A

HOUSE FIRE. IF ANY PORTION OF

THE HEATER OR ANY CHIMNEY

CONNECTOR GLOWS RED OR DIS-

COLORS, THE HEATER IS BEING

OVERFIRED.

CAUTION: DO NOT OPERATE THIS

HEATER WITH FEED OR ASH DOOR

OPEN. THIS HEATER IS DESIGNED

FOR THERMOSTATIC OPERATION.

OPERATION WITH EITHER DOOR

OPEN WILL OVERHEAT AND DAM-

AGE THE HEATER.

CAUTION:NEVER STORE FLAM-

MABLE LIQUIDS, ESPECIALLY

GASOLINE,IN THEVICINITY OFTHE

HEATER.

CAUTION: NEVER USE THE MANU-

FACTURED COAL BRICKS THAT

ARE MADE FROM COAL DUST AND

A WAX-TYPE BINDER.

WARNING: THE USE OF WOOD IN

THIS STOVE EXCEPT FOR COAL IG-

NITIONPURPOSES,ISA VIOLATION

OF FEDERAL LAW.

CAUTION: GASES THAT ARE

DRIVEN FROM FRESH COAL MUST

BE BURNED OR THEY WILL ACCU-

MULATE AND EXPLODE. NEVER

SMOTHER A FIRE WHEN ADDING

FRESH COAL.

CAUTION: NEVER USE GASOLINE,

GASOLINE-TYPE LANTERN FUEL,

KEROSENE, CHARCOAL LIGHTER

FLUID, OR SIMILAR LIQUIDS TO

STARTOR"FRESHENUP"AFIRE IN

THE HEATER.

ADJUSTING THE THERMOSTAT

The thermostat control was calibrated

atthefactory.Theoperationoftheheater

may require a change in calibration.

Calibrationadjustmentsshouldbemade

at room temperature.

If the room temperature is not satisfac-

tory, the thermostat operating range

may be changed as follows:

A. To increase the amount of heat at a

"HIGH" setting, adjust the wire link-

age to increase the draft damper

opening (Fig. 9).

1. Unhook linkage wire at point C

2. Take point A in left hand and B

right hand then turn B clockwise

about 3 turns.

3. Then hook linkage wire back to

draft control damper door at

point C.

B. To decrease the amount of heat at

"LOW" setting:

1. Check feed and ash doors to be

sure that they are closed tightly.

2. Check the connector pipe to see

that it is sealed in the flue collar

and at all joints.

3. If no air leaks are found, adjust

linkage the same as above,

except turn B counterclockwise

about 3 turns.

C. Adjusting the minimum Air Shutter:

The minimum air shutter has an

infinite number of settings. Several

adjustments may be necessary for

the unit to work most effectively for

your particular installation.

1. The minimum air shutter may be

adjusted to the closed position in

installations where the draft is

"above normal". Generally, .06

w.c. or above would be consid-

ered "above normal".

2. In installation where the draft is

"below normal", the minimum air

shutter would be adjusted toward

the open position.

10 11

MINIMUM FIRE

AIR SHUTTER

B

A

Fig. 9

NOTE: More than one recalibration

may be necessary. At room temp.

(72*F) and "Low" setting, the draft

damper door should be closed.

(C)