List of Figures

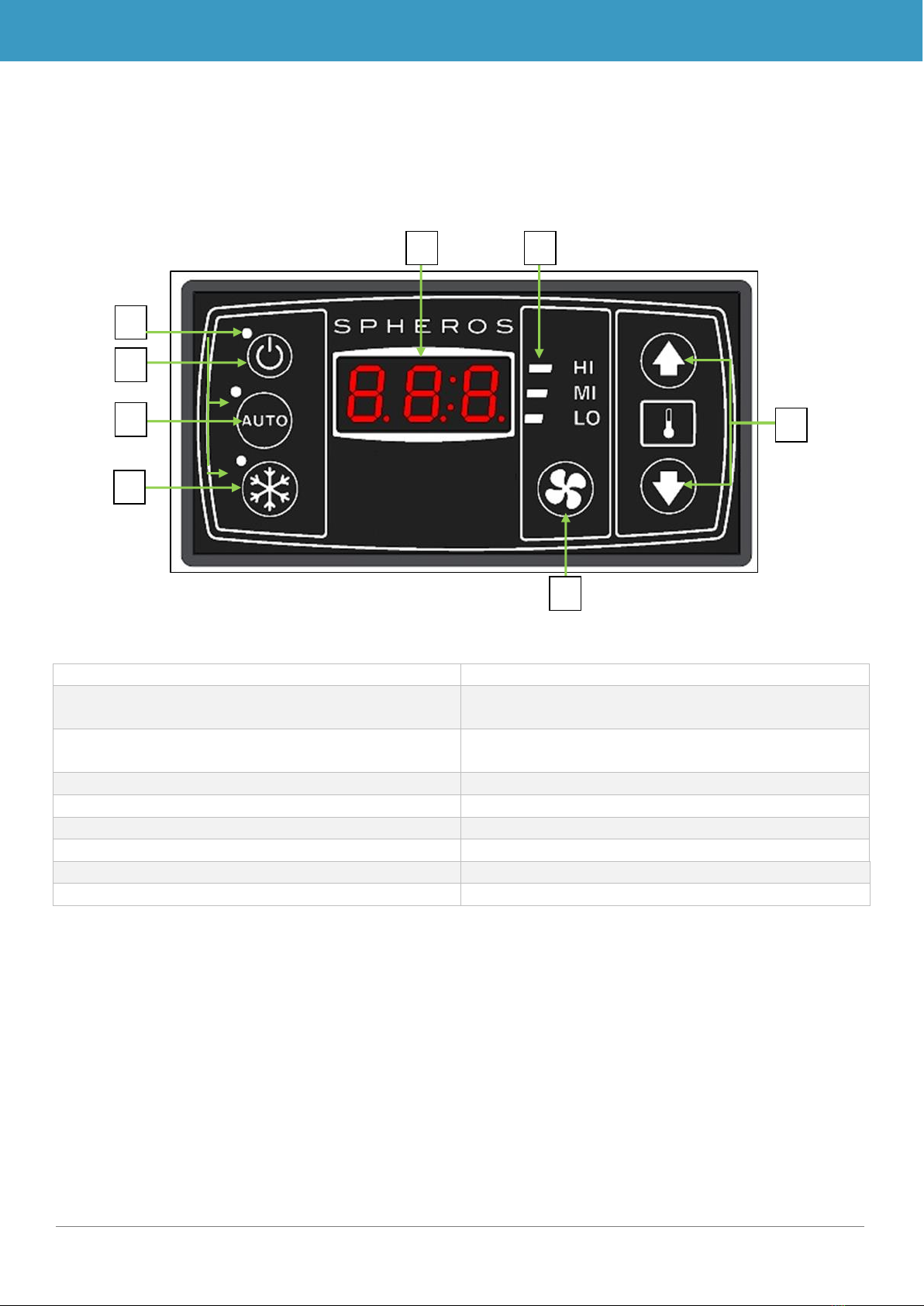

Figure 1 - SC400 control panel..................................................................................4

Figure 2 - SC410 control panel..................................................................................5

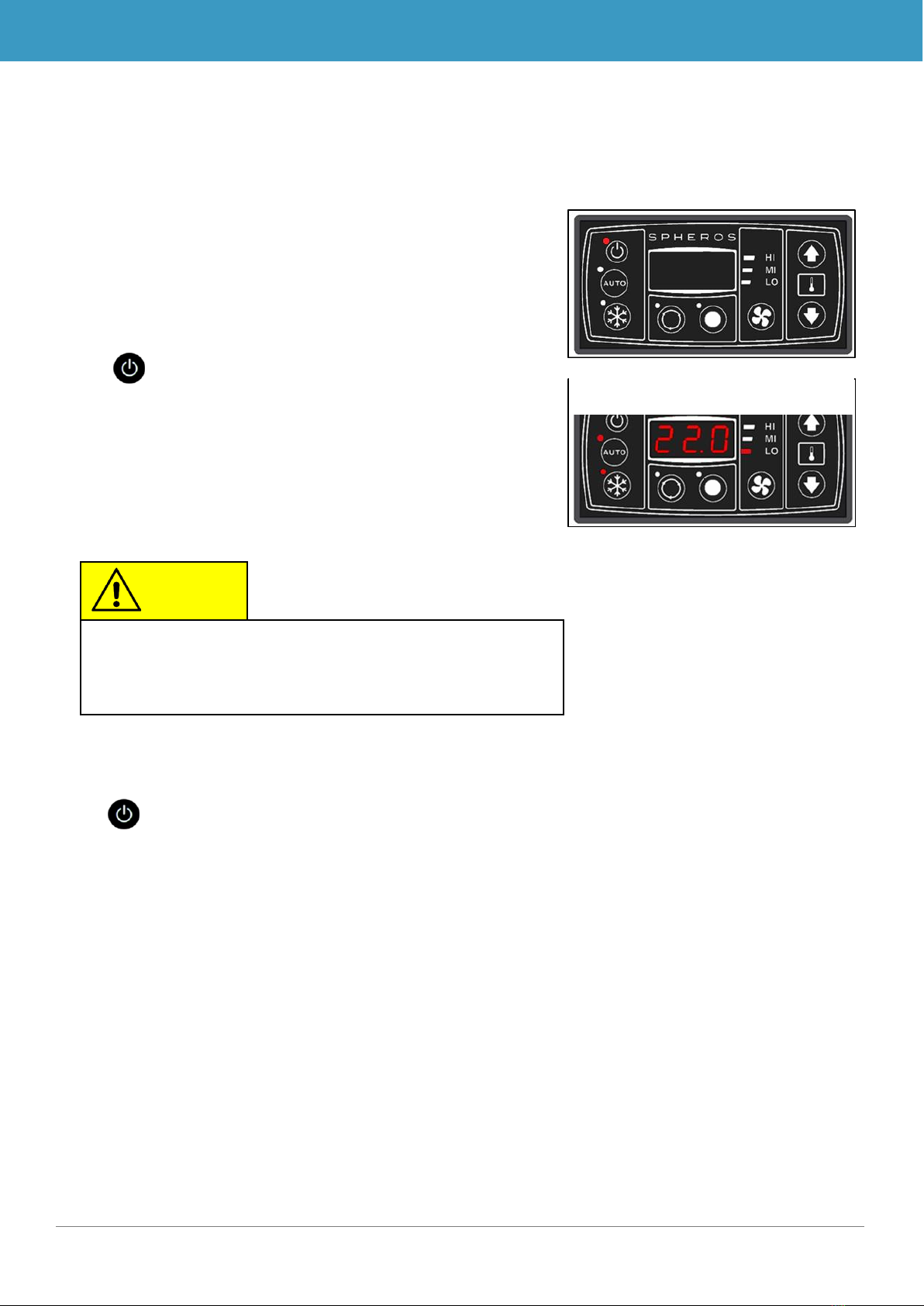

Figure 3 - SC410 Standby........................................................................................6

Figure 4 - SC410 example start display after activation.....................................................6

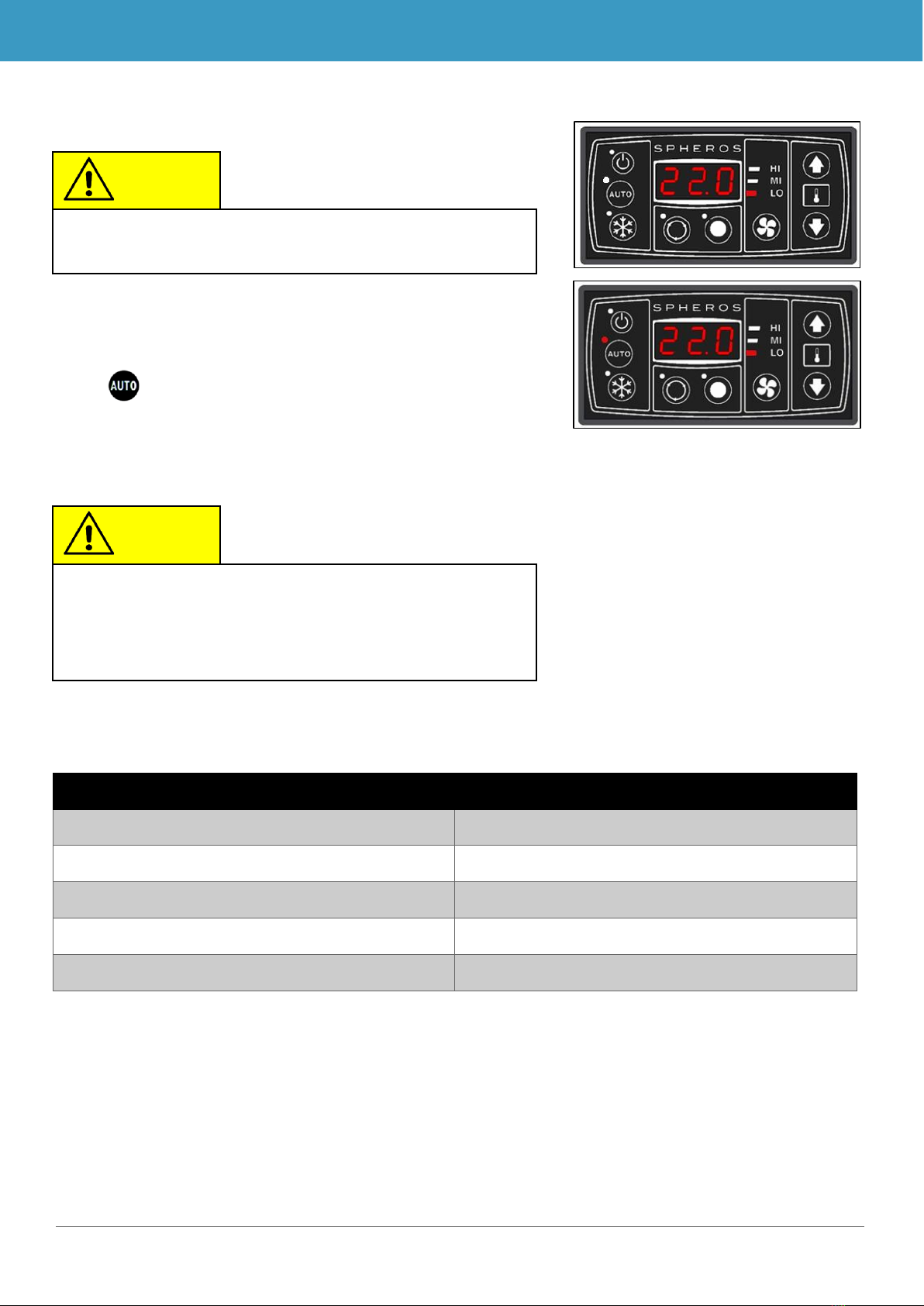

Figure 5 - SC410 control panel before and after activating Auto mode...................................7

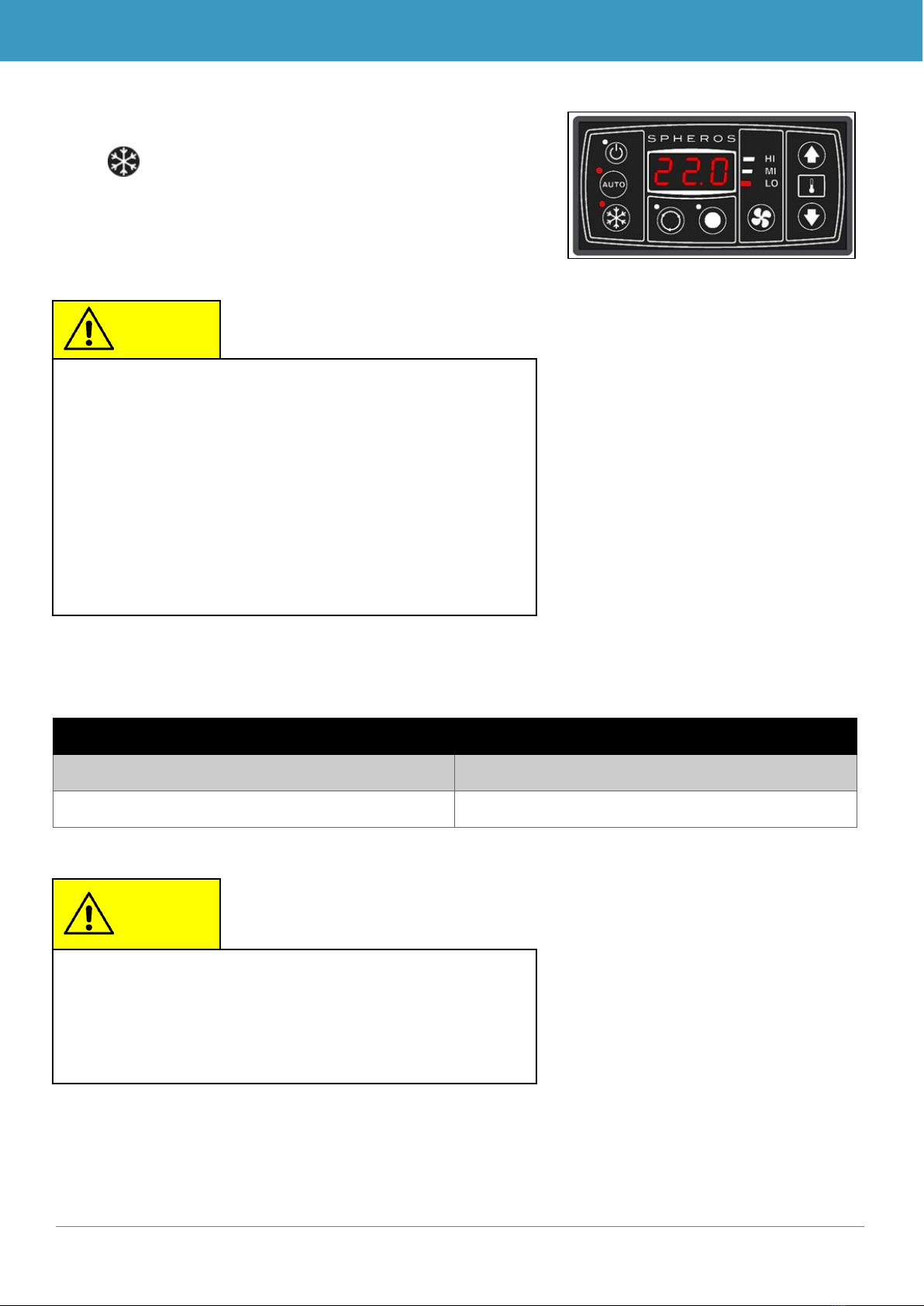

Figure 6 - SC410 air-conditioning compressor deactivated.................................................8

Figure 7 - SC410 air-conditioning compressor/Auto mode activated .....................................9

Figure 8 –SC410 changing the temperature ............................................................... 10

Figure 9 - SC410 changing the temperature ................................................................ 10

Figure 10 - SC410 blower level from lower to medium speed............................................ 11

Figure 11 - SC410 blower level at high speed.............................................................. 11

Figure 12 - SC410 blower level at low speed ............................................................... 11

Figure 13 - SC410 recirculating air function active......................................................... 12

Figure 14 - SC410 fresh air valves open..................................................................... 12

Figure 15 –SC410 additional component switched on.................................................... 13

Figure 16 - SC410 error display............................................................................... 14

List of Tables

Table 1 - SC400/410 temperature difference and blower level in cooling mode ........................7

Table 2 - SC410 temperature difference and blower level in heating mode .............................8

Table 3 - SC410 Temperature Difference Compressor .....................................................8

Table 4 - SC410 Temperatur Difference Water Valve + Electric Water Pump ..........................9

Table 5 - Error code overview ................................................................................. 15