Release 08/21

High-Containment Roadside Safety Barrier

10

HIGHWAY

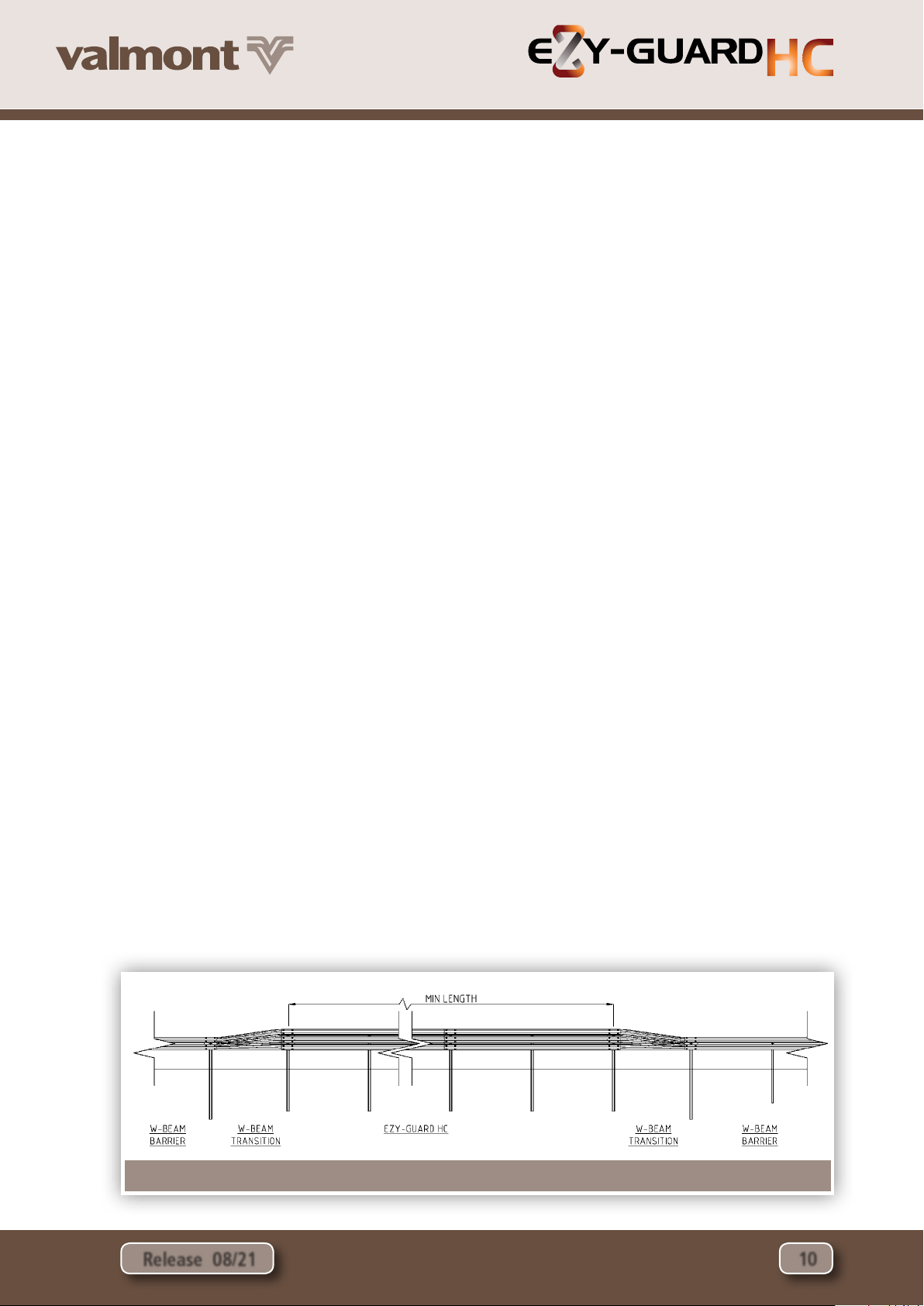

7.2 Minimum Length Requirements

There are two geometric methods used to determine the likely

trajectory of a vehicle that leaves the road in the vicinity of a

roadside hazard and the minimum length of barrier required

to protect from this hazard.

The most common method is the run-out length method and

an alternative is a method based on angle of departure.

Prior to design or installation, designers should consult the

relevant road controlling authority to establish the local

jurisdictional practice as the methods may result in dierent

lengths. Both methods are detailed in the Austroads Guide

to Road Design – Part 6.3.

For instances where geometric constraints limit the

installation of the recommended length under the above

design methods, the absolute minimum length of minimum

length of need for Ezy-Guard HC is dependent on the design

containment level. For measurement of minimum installed

length, refer Figure 6 below.

• MASH Test Level 3 containment, where the design vehicle

is a 2,270kg pick-up, the minimum length of Ezy-Guard

HC is 20m.

• MASH Test Level 4 containment, where the design vehicle

is a 10,000kg truck, the minimum length of Ezy-Guard HC

is 26m.

7.3 Sequence of Work

Where Ezy-Guard HC is being constructed on a road open

to traffic, it is recommended that the work commence at the

end closest to the approaching traffic. Leading terminals and

transitions shall be commissioned at the earliest practical time.

7.4 Modifications

Ezy-Guard HC shall be constructed in the configuration

as detailed in Valmont Highway’s drawings. This is the

configuration in which the system has been crash tested. No

modifications shall be made to the system unless verified by

Valmont Highway.

Flame cutting of rails or posts is not permitted. Saw cutting

and drilling is permitted in the event that a post is to be

installed at an irregular spacing and/or rock is encountered

and the post embedment depth has been modified.

Any modification carried out after fabrication will require

repair to the galvanized coating. This is undertaken by

applying two coats of an organic zinc rich epoxy paint

complying with AS/NZS 3750.9. This is to be applied to the

repair areas in two coats. Each coat shall have a minimum

dry film thickness of 50 μm.

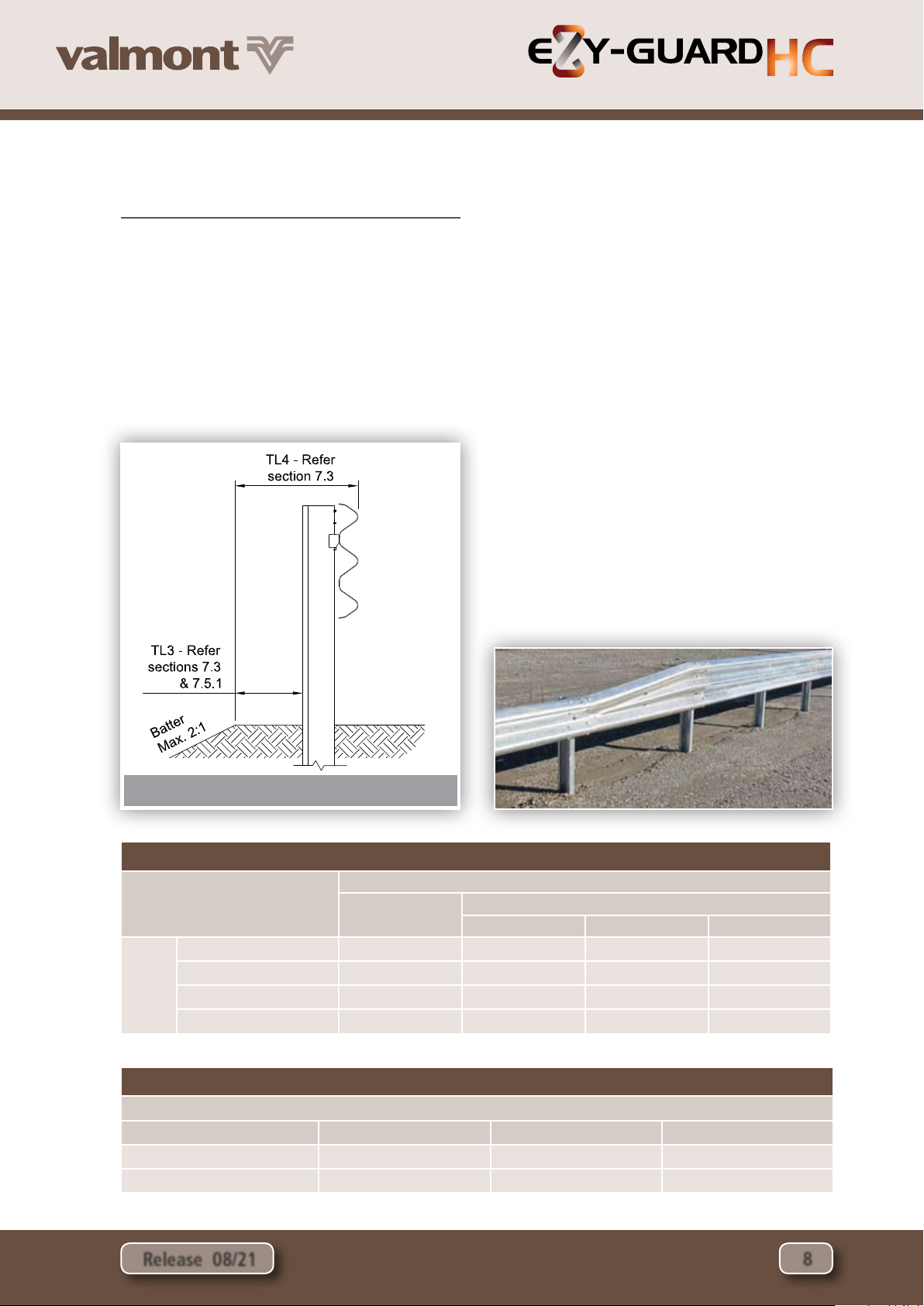

7.5 Soil Requirements & Embedment Depth

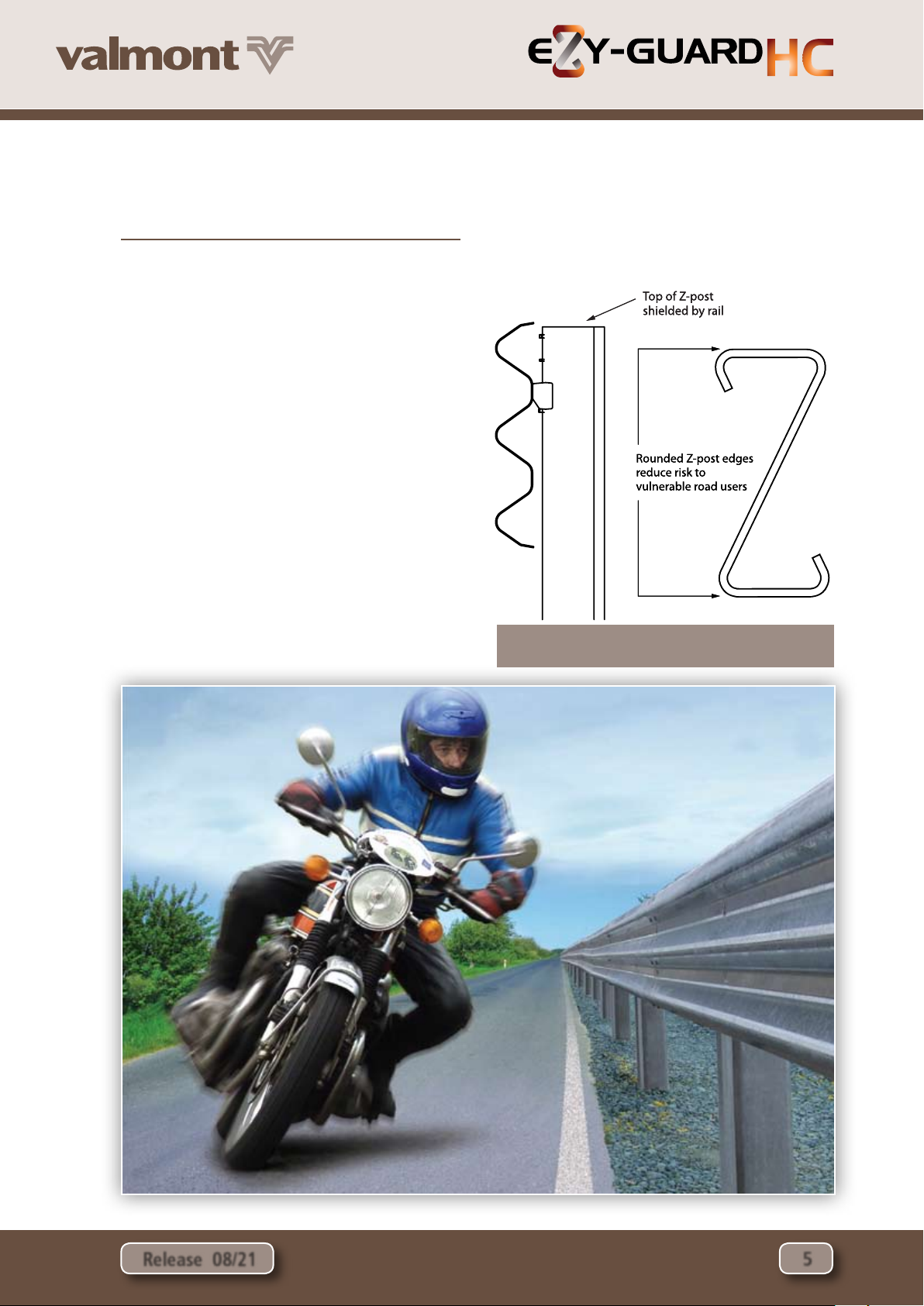

The Z-post is designed to yield by bending near ground level

during impact. Provided the post is embedded in material

that allows this failure mechanism to be replicated, the Ezy-

Guard HC functionality will be retained. The Z-posts will

provide lateral resistance until the impacting vehicle causes

deformation of the posts. At this point the Ezy-HC-Carriages

will provide a controlled release of the rail from the Z-posts

resulting in safe vehicle containment and redirection.

7.5.1 Standard Soil

Ezy-Guard HC has been evaluated for installation in standard

soil in accordance with AASHTO standard specifications for

‘Materials for Aggregate and Soil Aggregate Subbase, Base

and Surface Courses,’ designation M 147.

Change to:

When installed in weak soil, the 1,030mm embedment depth

of the Z-post is sucient for installation up to 500mm of the

rounding point on 2:1 embankment slopes. If installation

is required within 500mm of the rounding point, the post

embedment depth is required to be increased to 1,350mm.

A longer Z-post is available from Ingal Civil for these

applications.

For a TL4 containment level, installations within 1.7m from

the hinge point should be considered within the requirements

of the road controlling authority Extended Design Domain

requirements.

Figure 6. Minimum length measurement