5

◼Contents

1. INSTRUCTION MANUAL .................................................................................................................................................. 6

1.1 General information ............................................................................................................................................. 6

1.1.1 Machine identification ................................................................................................................................ 6

1.1.2 The permitted application ........................................................................................................................... 6

1.2 Precautions ........................................................................................................................................................... 7

1.2.1 General Precautions .................................................................................................................................... 7

1.2.2 P.T.O. driven machine ................................................................................................................................ 7

1.2.3 Service ........................................................................................................................................................ 8

1.3 Technical Information .......................................................................................................................................... 8

1.4 Putting in service of a unit.................................................................................................................................... 8

1.4.1 Fitting to the tractor .................................................................................................................................... 8

1.4.1.1 Mechanically .................................................................................................................................... 8

1.4.1.2 Hydraulically.................................................................................................................................... 9

1.4.2 Transport Safety Lock................................................................................................................................. 9

1.4.2.1 Lock cutter head:.............................................................................................................................. 9

1.4.2.2 Un-lock cutter head: ......................................................................................................................... 9

1.4.3 Obstacle Safety Device ............................................................................................................................... 9

1.4.4 Cutting height ........................................................................................................................................... 10

1.4.5 P.T.O. shaft ............................................................................................................................................... 10

1.4.6 Gearbox..................................................................................................................................................... 10

1.4.7 Transport................................................................................................................................................... 10

1.4.8 Overload coupling..................................................................................................................................... 11

1.5 Mechanical check-up.......................................................................................................................................... 11

1.6 Driving speed ..................................................................................................................................................... 11

1.7 Gearbox .............................................................................................................................................................. 11

1.8 Power Belt .......................................................................................................................................................... 12

1.9 Flails ................................................................................................................................................................... 13

1.9.1 General...................................................................................................................................................... 13

1.9.2 In service................................................................................................................................................... 13

1.9.3 Replacement of flails ................................................................................................................................ 13

1.10 Service................................................................................................................................................................ 13

1.10.1 P.T.O. shaft................................................................................................................................................ 13

1.10.2 Overloading clutch P.T.O. shaft................................................................................................................ 14

1.10.3 Bearing houses flail rotor.......................................................................................................................... 14

1.10.4 Bearing houses drive shaft ........................................................................................................................ 14

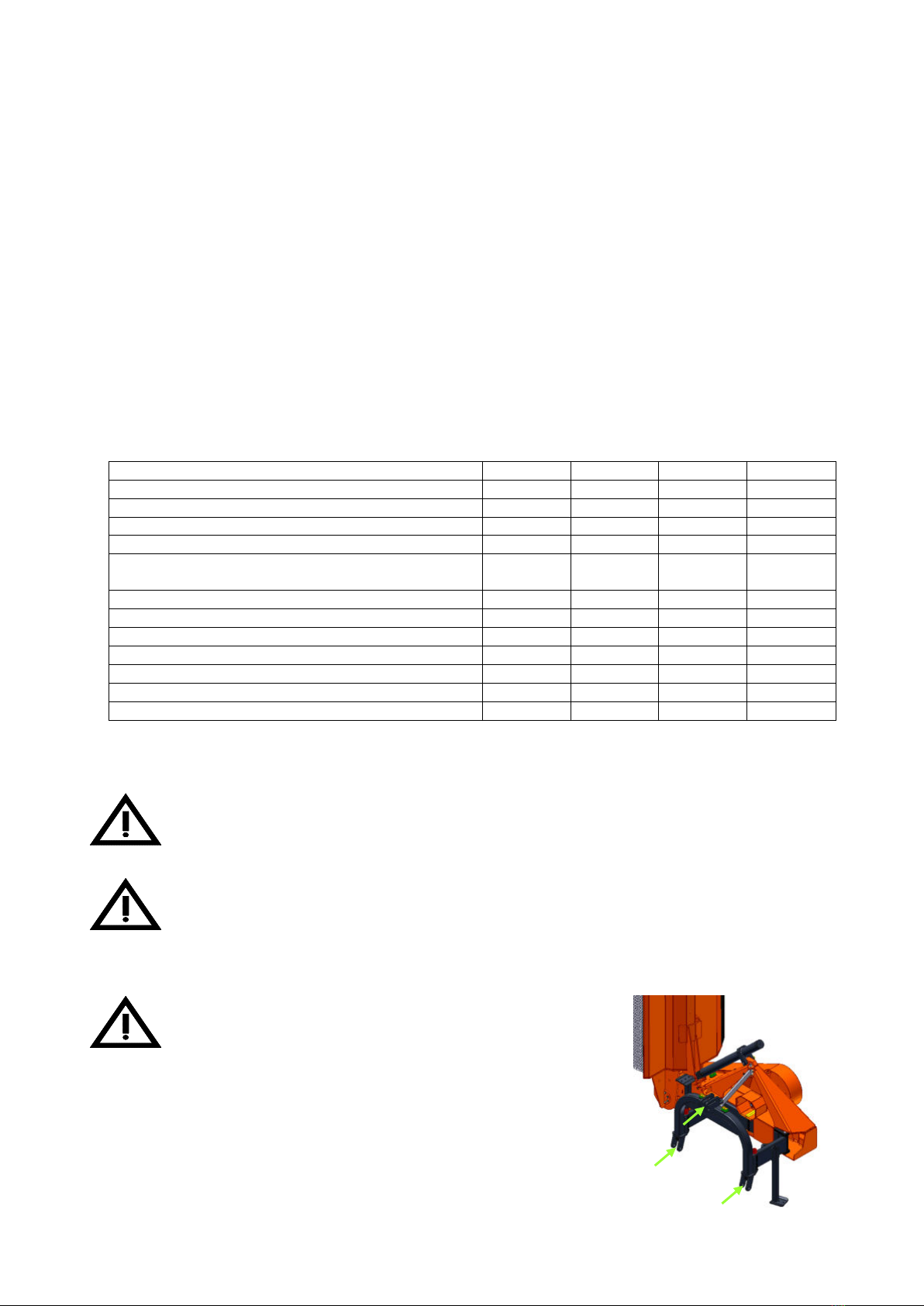

1.10.5 Parallelogram Offset system ..................................................................................................................... 14

1.10.6 Pivot points cutting head........................................................................................................................... 14

1.10.7 Replacement of bearing bushings. ............................................................................................................ 15

1.10.8 Pivot points of cutting head ram ............................................................................................................... 15

1.10.9 Rear roller ................................................................................................................................................. 15

1.10.10 Obstacle Safety device.............................................................................................................................. 15

1.10.11 Sliding part Hydro-Lift ............................................................................................................................. 15

1.10.12 General grease advise ............................................................................................................................... 15

1.11 Important advises ............................................................................................................................................... 16

1.11.1 Winter services ......................................................................................................................................... 16

1.11.2 Repair........................................................................................................................................................ 16

1.11.3 Torque Moments bolt connections............................................................................................................ 16

1.12 Failure table........................................................................................................................................................ 17

1.13 Safety decals....................................................................................................................................................... 19

1.14 Declaration of Conformity ................................................................................................................................. 19