REV 1 SGT-600 USER’S MANUAL

ii

TABLE OF CONTENTS

CONVENTIONS USED IN THIS DOCUMENT ..................................................................................... 1

1.0 INTRODUCTION.................................................................................................................... 2

1.1 General Description and Features ................................................................................... 2

1.2 SGT-600 Technical Specifications .................................................................................... 4

1.3 SGT-600 Controls and Indicators ..................................................................................... 5

2.0 PRE-TEST SETUP ................................................................................................................... 6

2.1 Operating Voltages .......................................................................................................... 6

2.2 LCD Screen Contrast Control............................................................................................ 6

3.0 OPERATING PROCEDURES ................................................................................................... 7

3.1 Connection Diagrams....................................................................................................... 7

3.3 Setting the Interface Language........................................................................................ 9

3.4 Setting the Option to Print the Calibration Expiration Date.......................................... 10

3.5 Testing Procedures ........................................................................................................ 12

3.5.1. Entering Test Record Header Information ............................................................. 12

3.5.2. Performing a Test ................................................................................................... 15

3.5.3. Performing Diagnostic Tests .......................................................................................... 20

3.6 Working With Test Records ........................................................................................... 24

3.6.1. Viewing the Contents of the Working Memory ..................................................... 24

3.6.2. Saving Test Results to a Test Record ...................................................................... 26

3.6.3. Restoring a Test Record From Flash EEPROM........................................................ 28

3.6.4. Restoring a Test Record From a USB Flash Drive ................................................... 32

3.6.5. Copying Test Records to a USB Flash Drive............................................................ 34

3.6.6. Printing the Test Record Directory......................................................................... 37

3.6.7. Erasing Test Records from the Unit's Flash EEPROM............................................. 40

3.6.8. Erasing Test Records from a USB Flash Drive......................................................... 45

4.0 Getting the Latest Firmware, Software, and Manuals....................................................... 48

LIST OF FIGURES

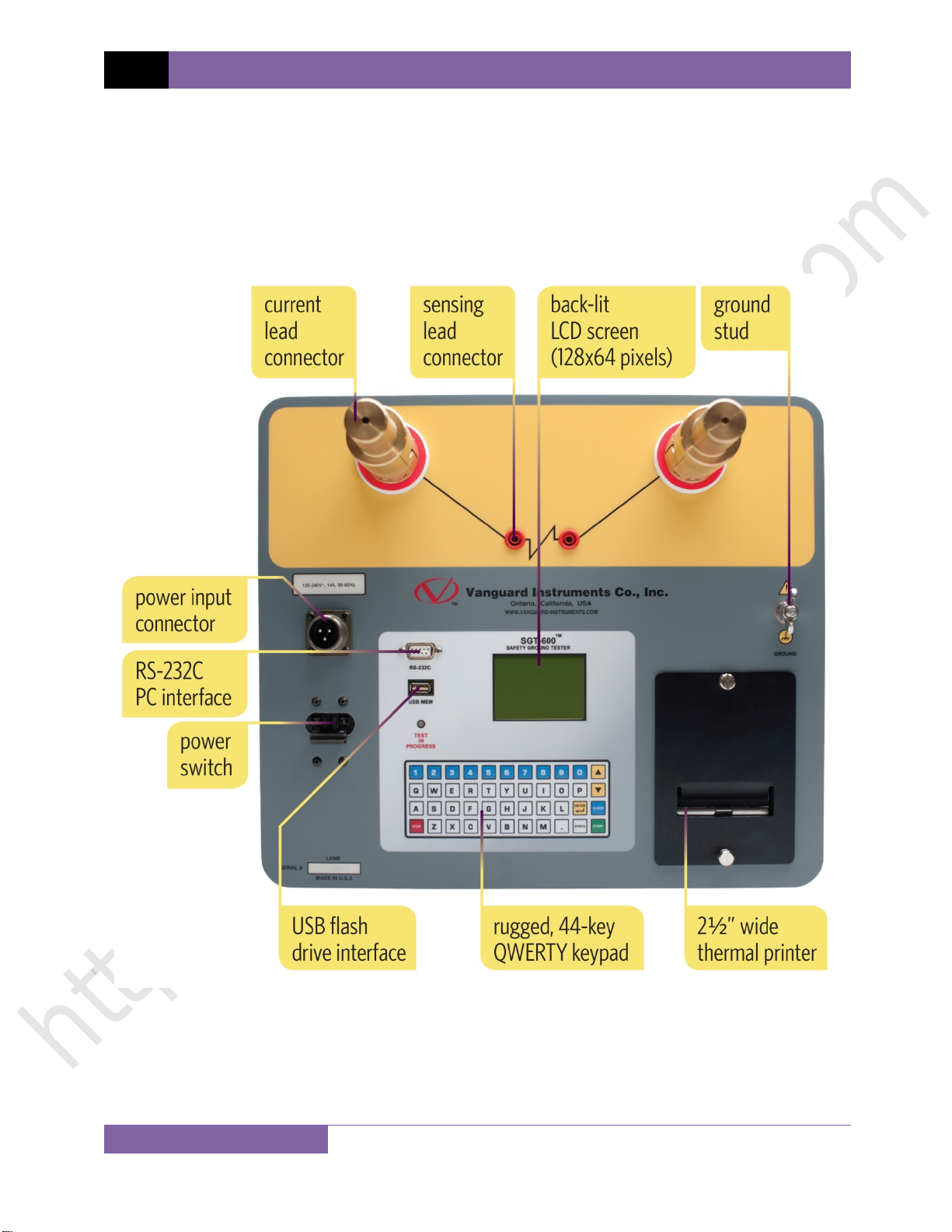

Figure 1. SGT-600 Controls and Indicators ..................................................................................... 5

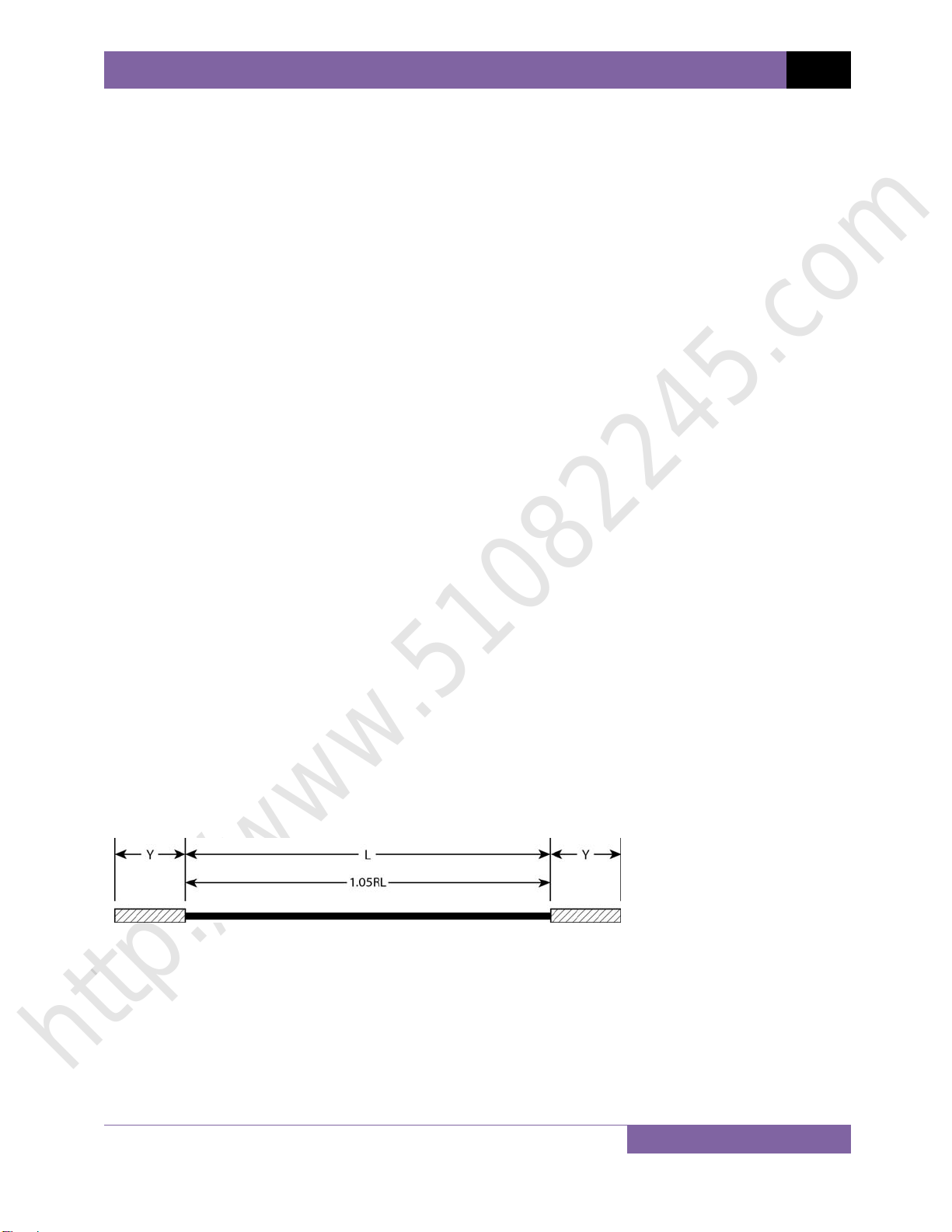

Figure 2. Typical SGT-600 Connection Diagram.............................................................................. 7

Figure 3. Sample Test Report Printout with Calibration Expiration Date..................................... 11

Figure 4. Sample SGT-600 Test Results Printouts......................................................................... 19

Figure 5. Performing a Diagnostic Test Between Points A and B ................................................. 20

Figure 6. Sample Diagnostic Test Results Printout ....................................................................... 23

Figure 7. Sample Thumb Drive Directory Printout ....................................................................... 39

Figure 8. Sample Internal Test Record Directory Printout............................................................ 39