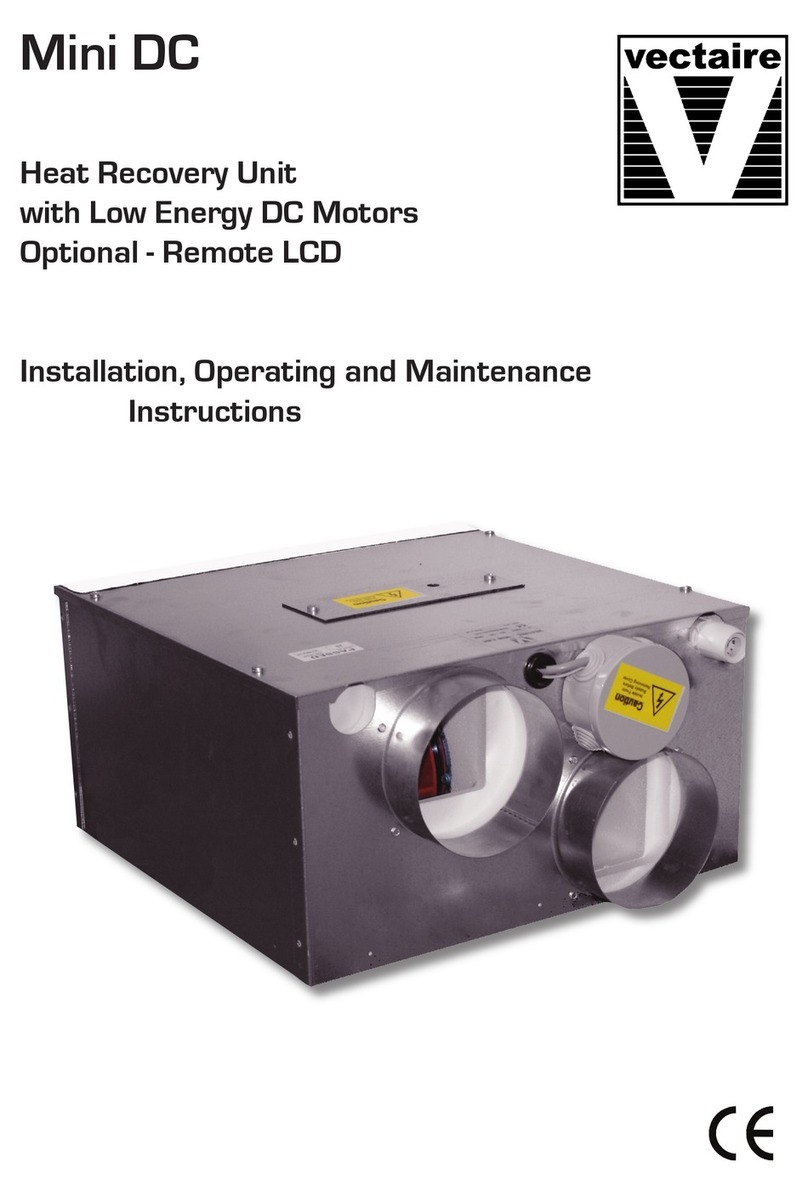

"STUDIO" - HEAT RECOVERY UNIT

INSTALLATION AND OPERATING INSTRUCTIONS

SAFETY NOTICE

It is important to read this Instruction Manual carefully before installing or using the product. Following

these instructions will ensure that your ventilation system is installed, commissioned and used properly

and continues to operate effectively. Vectaire will not be held responsible and will not accept liability

for any damage caused to persons or property through failure to follow the guidance provided in this

manual. It should always be available with the product for easy reference.

Your unit SHOULD NOT be switched off (except during maintenance). It is designed to run continuously.

If it is switched off indoor pollutant and moisture levels may increase.

Studio: 125mm spigot, for continuous venti ation

Max airf ow 63 /s

GENERAL INFORMATION

The Vectaire Studio heat recovery system provides mechanica ven-

ti ation to bedrooms and bathrooms. It extracts sta e, contaminated

air from bathrooms, rep aces it with fresh air to the bedroom and

vents the sta e air to the outside.

Heat is rec aimed from the extracted air and used, via a heat

exchanger, to warm the incoming fresh air. The extract and intake

airstreams are comp ete y separate to avoid cross-contamination.

The system operates continuous y and is designed not be switched

off, except for maintenance purposes.

During norma operation, the unit produces a ow-vo ume airf ow,

creating a comfortab e, hea thy environment, with minimum energy consumption.

If additiona venti ation is required, (e.g. when a shower is in use), a boost faci ity is

inc uded which increases the airf ow rate. The boost can be operated automatica y

or manua y.

Insta ation of the unit is usua y above a cei ing or in a oft space and is connected

to air vents via hidden ductwork.

Each unit is commissioned individua y a owing its performance to be matched to the size of area to be ven-

ti ated.

STANDARD FEATURES

1. Variab e adjustment of ow (trick e) and boost speeds for optimum setting at insta ation.

2. Adjustab e overrun timer on boost setting - factory set to zero.

3. Adjustab e de ay-on timer, factory set to 2 minutes

4. Adjustab e night-time boost inhibitor set to operate from 10.00 p.m to 6.00 a.m

5. Mu tip e choice of externa devices for automatic or manua boost switching (e.g. ight switch, remote

switch/pu cord, PIRFF passive infra-red*, DRH240 humidistat*, THM thermostat*.)

*Note : Contact Vectaire for supp y of these items.

OPTIONAL ADDITIONAL FEATURE

BMS connections for remote motor shut-off.

Page 2

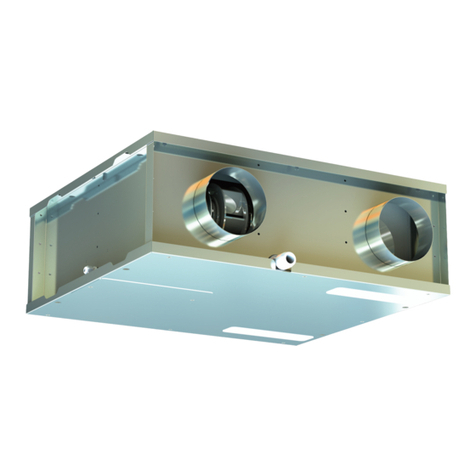

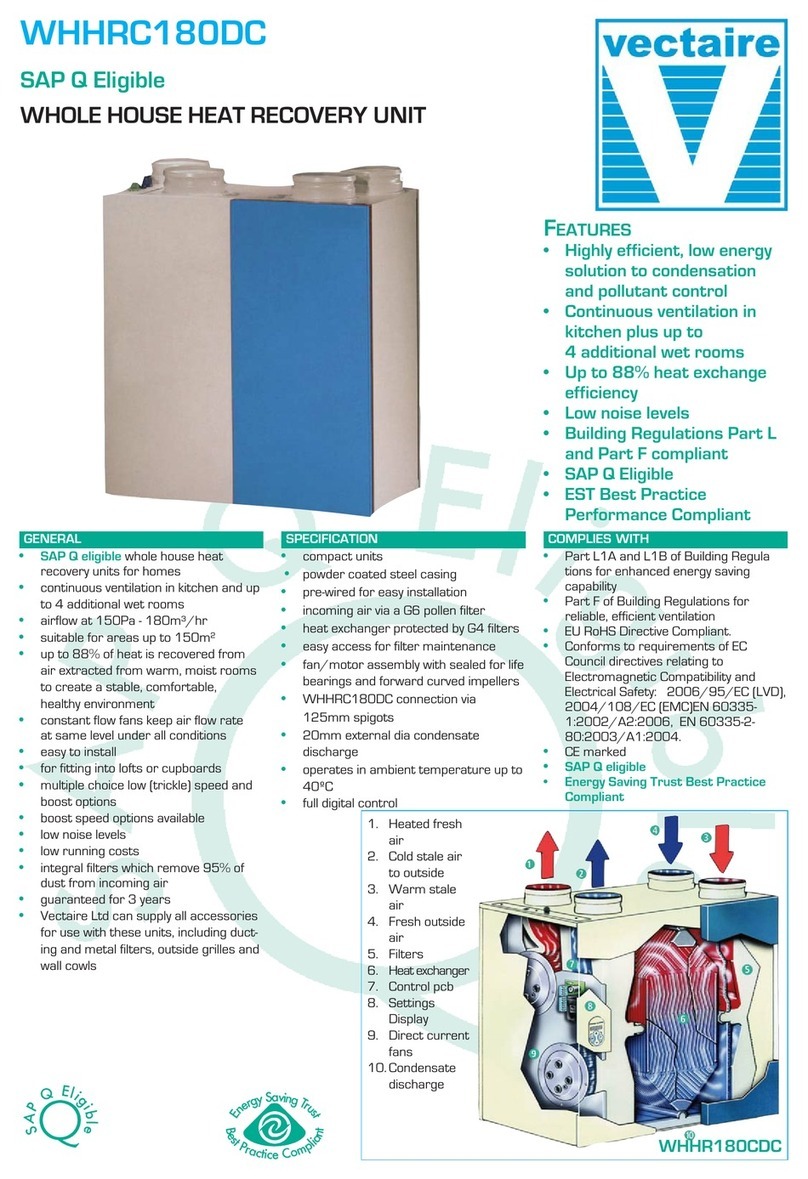

Incoming fresh air

Warmed fresh air

Extracted warm,

moist, stale air

Cooled outgoing

stale air

Studio

GENERAL SAFETY

PLEASE READ THESE INSTRUCTIONS FULLY, BEFORE ATTEMPTING ANY INSTALLATION

1. This product must not be used for any purpose other than that for which it was designed and shown

in this eaf et.

2. A packaging shou d be removed and the unit checked for damage. If any damage is found, contact

your supp ier.

3. This product wi norma y be fitted into a oft or cei ing void.

In order to comply with Construction (Design & Management) Regulations, sufficient access for

safe maintenance (recommended on an annual basis), or removal following installation, MUST be

provided for this product. See dimensions above.

4. The unit must NOT be insta ed:

- where there is excessive oi or grease

- where there are hazardous gases, iquids or vapours that are f ammab e or corrosive

- in ambient temperatures above 50ºC or ower than 5ºC

- in humidity eve s above 90% or in a wet environment

5. If any room from which air is extracted contains a fuel burning appliance, such as a central heating

boiler, then its flue must be of the sealed or balanced flue type, or allowance must be made for an

adequate supply of air into the room.

6. The mains supp y vo tage and power rating must comp y with the detai s on the product rating abe .

Page 3

DIMENSIONS - mm

N.B a c earance of

at east 200 mm

shou d be a owed

at the rear of the

unit in order to re-

pace fi ters. A

c earance of

220mm shou d be

a owed at bottom

of unit when in-

sta ed for access

to the heat ex-

changer

*236mm with mounting bracket on drain side

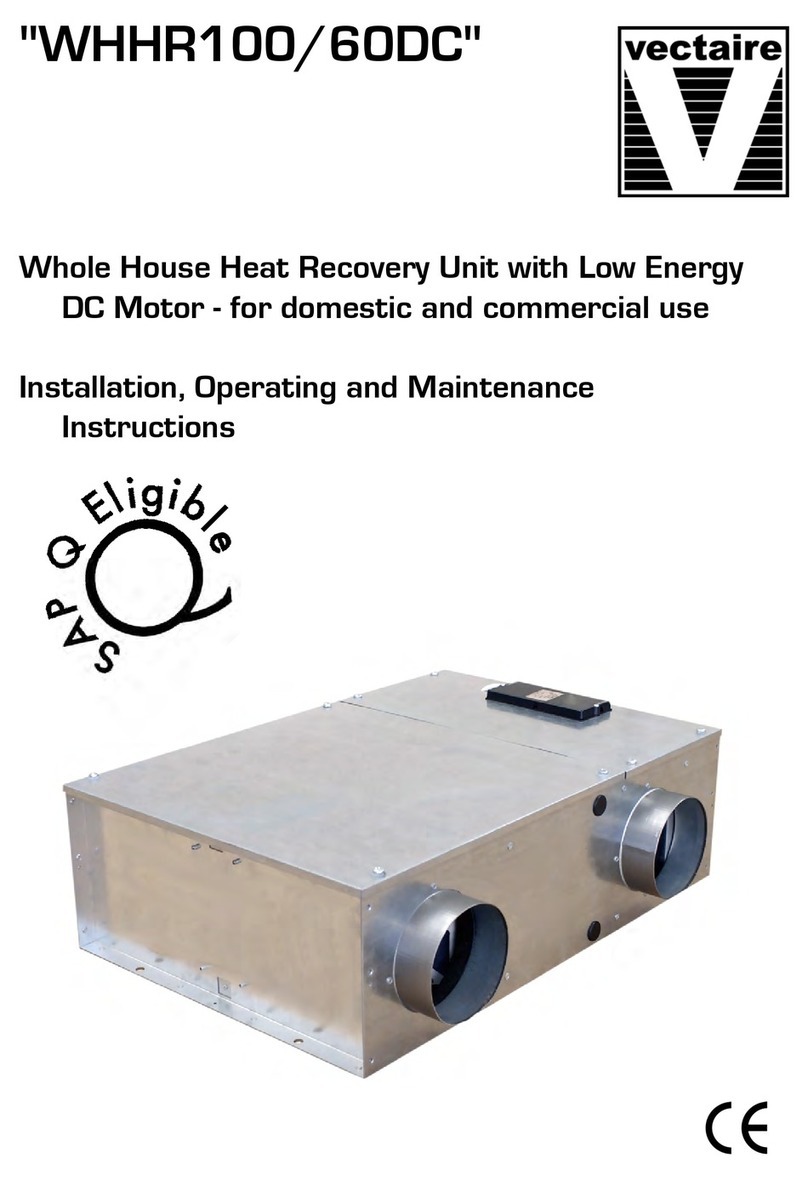

INSTALLATION

Installation must be carried out by a suitably qualified person and must comply with all current building

regulations and electrical installation regulations.

Mounting the unit

Before choosing the position for mounting, it is important to take into consideration the ductwork routes

and condensate drain route. The four spigots on the unit are marked for the four unique connections. The

unit can be supp ied eft or right-handed in order to match the required duct routes more easi y. (Factory

option on y.)

It is also essential that adequate access to the

product is provided for maintenance or removal

after installation. The entire access panel needs to

be removed for maintenance.

The unit is intended to be suspended from a cei ing

or simi ar fixture. Two identica fixing brackets are

supp ied with each unit. It is important that the unit

is attached to ithese brackets so that there is a s ope

down towards the condensation drain connector of

the product. When correct y fitted, the brackets wi

provide a drop of approximate y 15mm at the ower

end.

Duct and Duct Connections (refer to design drawing)

1.4 x 125mm nomina diameter spigots are provided for the connection of ducting. These are c ear y

marked for correct connection of the supp y and exhaust ducts.

2. Where ducting is insta ed in an unheated space, a of the ducts shou d be insu ated. Where ducting is

insta ed in a heated space, on y the co d ducts shou d be insu ated. i.e. the supp y duct from outside and

the extract duct from the unit to the outside.

3.The duct ayout must be designed to suit the requirements of the venti ation/heat recovery system and

bui ding ayout. If the ducting passes through a fire wa /barrier, suitab e fire dampers must be

insta ed.

4. Where rigid duct is used (preferab e), it shou d be insta ed using the east number of fittings to min

imise air f ow resistance. Where possib e, fina connection to the gri es and unit shou d be made with

a f exib e connection.

5. Where f exib e ducts are used, ensure that:

- duct runs are kept as short as possib e

- the duct is stretched so that it is smooth and straight

- where bends are necessary, they have arge radii (ie avoid sharp bends)

- the duct is not crushed if in a restricted area

Note: Whenever the unit is insta ed in c ose proximity to a bedroom or other habitab e space, we recom-

mend that sound attenuation is provided within the duct runs between the rooms and the unit. A ength of

1 metre of f exib e acoustic ducting wi be sufficient in most circumstances, but reference shou d be made

to the sound data provided for this product

Page 4

Diagram showing slope towards drain

Studio - option 1 (right hand drain) Studio - option 2 (left hand drain)