Page 2

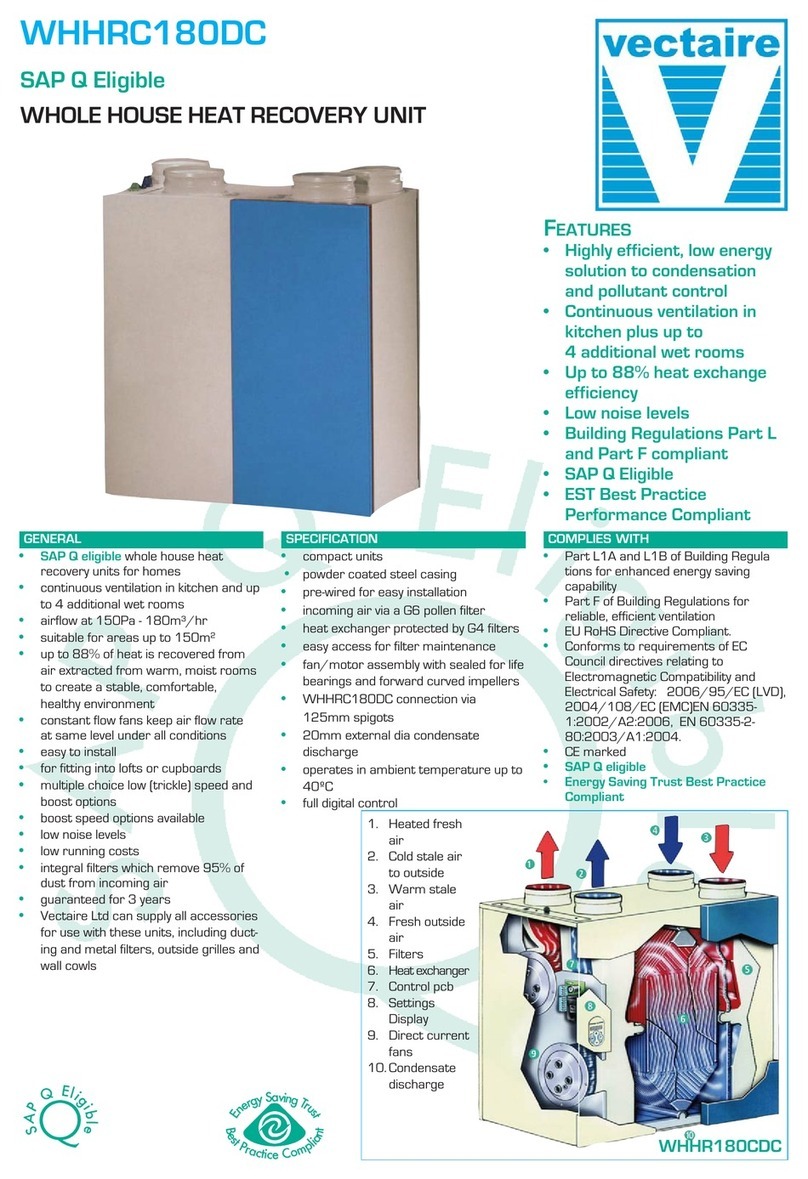

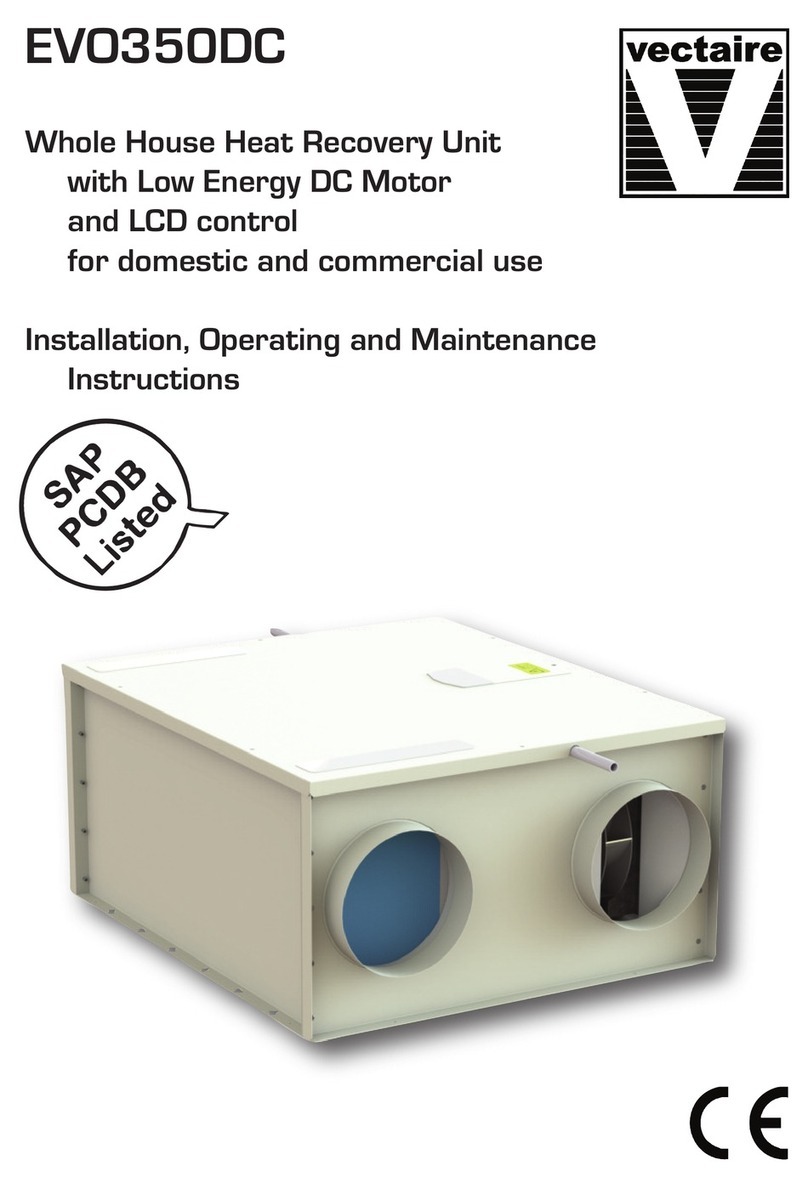

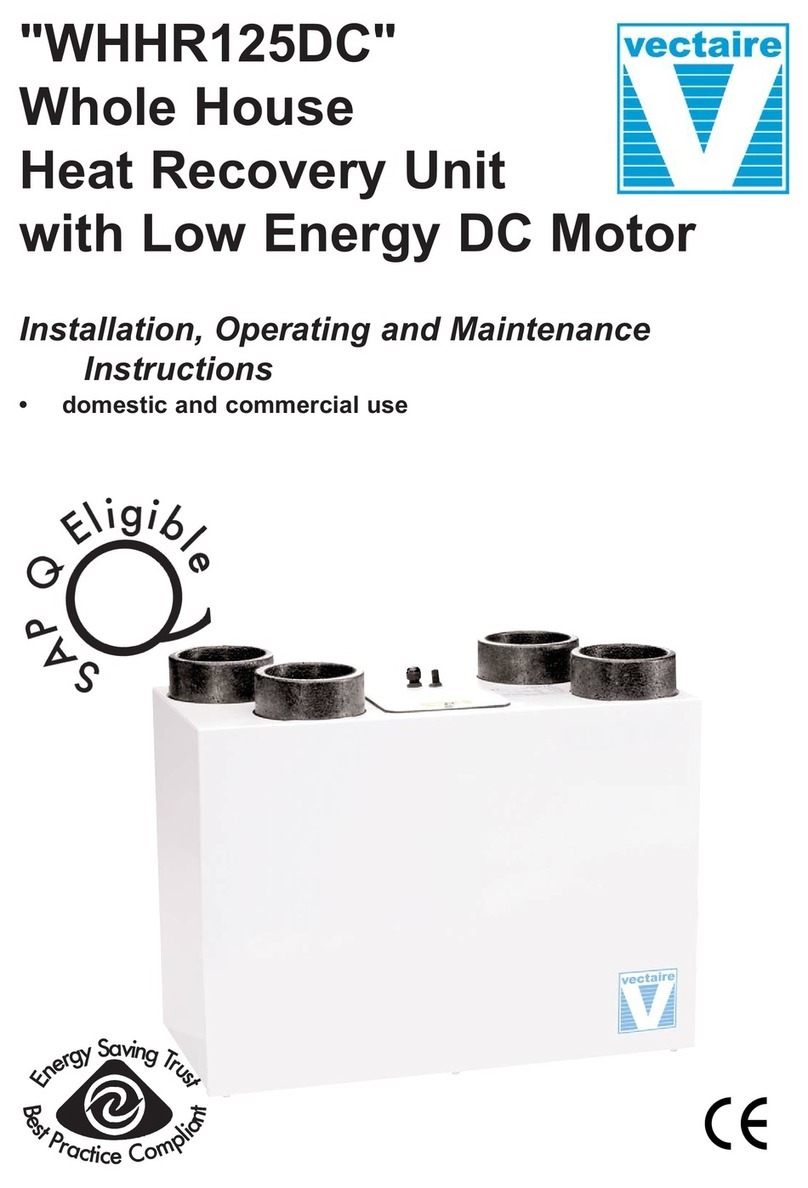

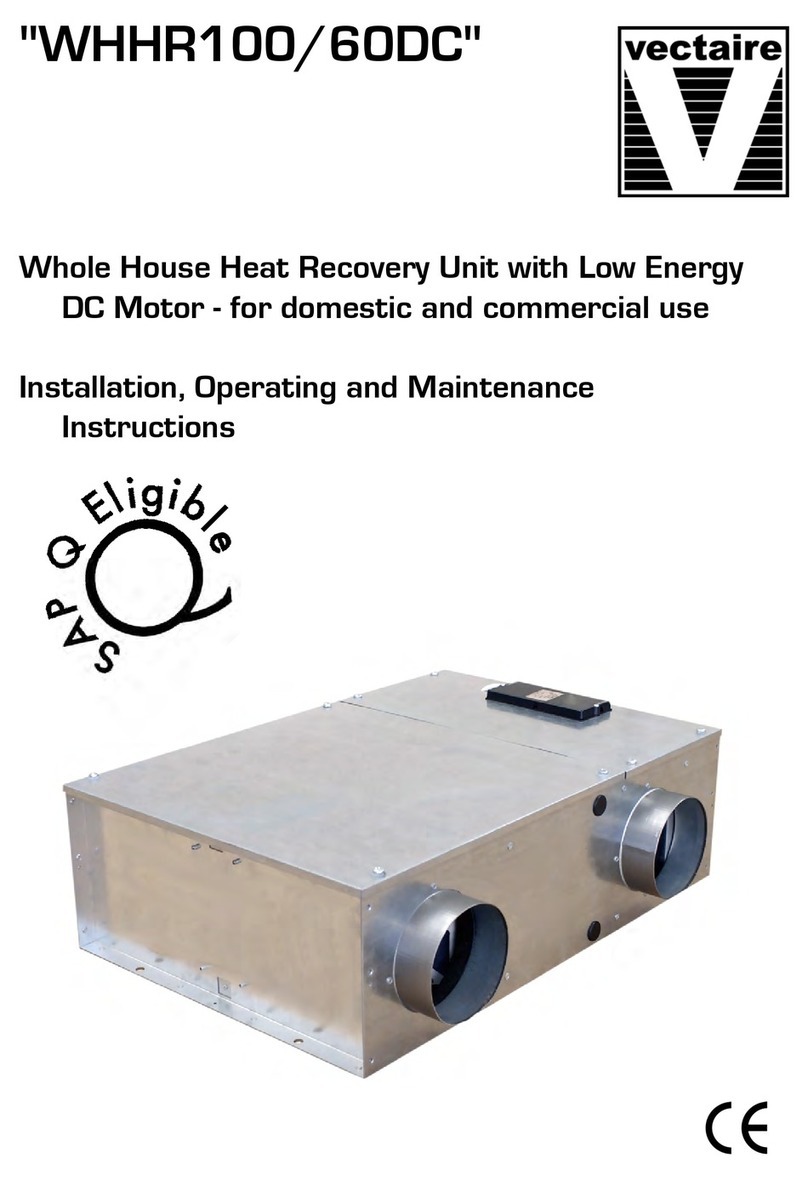

"EVO250DC" - WHOLE HOUSE HEAT RECOVERY UNIT

INSTALLATION AND OPERATING INSTRUCTIONS

Safety Notice

It is important to read this Instruction Manua carefu y before insta ing or using the product. Fo owing these

instructions wi ensure that your venti ation system is insta ed, commissioned and used proper y and contin-

ues to operate effective y. Vectaire wi not be he d responsib e and wi not accept iabi ity for any damage

caused to persons or property through fai ure to fo ow the guidance provided in this manua . It shou d a ways

be avai ab e with the product for easy reference.

EVO250DC: for dwe ings up to 150m2- maximum capacity 85m /sec

-Genera Information

The Vectaire EVO250DC heat recovery system provides who e house

mechanica venti ation to iving areas, bedrooms, kitchen and bathrooms

.

It extracts sta e, contaminated air from kitchens, uti ity rooms and bath-

rooms, and uses the heat recovered from this air to warm fresh, incom-

ing air to create a f ow of fresh air throughout the dwe ing. The extract

and intake air streams are separated to avoid contamination.

The system wi operate continuous y to create a stab e, comfortab e,

hea thy environment avoiding the use of excessive energy and saving

heat a ready generated.

The heat recovery unit wi genera y be insta ed in the oft of a house or

the void above the cei ing in an apartment (but may be insta ed in a cup-

board) and wi be connected by hidden ductwork to vents sited in the

cei ings of the rooms which require venti ation. Each unit is commis-

sioned individua y a owing its performance to be tai ored to suit the per-

formance required. There wi be a faci ity to boost the extraction rate

when desired (e.g when cooking or bathing or po utant eve s rise). This

may be done automatica y or manua y.

The system is designed to run continuous y and shou d NOT be switched off except for maintenance or fi ter

rep acement. It is important to fo ow the advice in this user manua and correct y insta and maintain the

system to ensure a hea thy and comfortab e indoor environment.

Features

• SAP PCDB Listed who e house heat recovery unit giving continuous venti ation in the kitchen and up to six

additiona wet rooms

• ow noise eve s

• variab e choice ow (trick e) speed and boost options for optimum setting at insta ation

• boost speed can be triggered by a switched ive connection from a variety of externa devices inc uding:

- a ight switch (if more than one ight switch is used, each one must be a doub e po e switch)

- DRH240 (dynamic remote humidistat)

- PIRFF (passive infra red)

- THM (thermostat)

- a remote switch/pu cord

or via LCD contro pane

• can be mounted with eft or right hand drainage and ducting.

• economica EC motor with e ectronic contro p us:

Standard contro features:

> Independent motor speed control

• Each motor can be adjusted independent y

• Trick e, boost and purge speeds can be set at insta ation

> Adjustable over-run timer - from 0-90 Minutes, factory set to 0 minutes

> Adjustable delay-on timer - from 0-5 Minutes, factory set to 2 minutes

> Integral frost stat – proportiona y reduces intake motor speed as temperature fa s

> BMS connections – for remote motor shut off

• Insta ation MUST be carried out by suitab y qua ified personne and MUST be in accordance with current IEE

regu ations

IT IS IMPORTANT THESE INSTRUCTIONS ARE

READ FULLY BEFORE INSTALLATION

•This product shou d not be used for any purpose

other than that for which it was designed and as

shown in this eaf et.

•A packaging shou d be removed and the unit

checked for damage in transit. If there is any

damage, p ease contact your supp ier.

• The EVO250DC wi genera y be fitted into a oft or

cei ing void. In order to comp y with Construction

(Design & Management) Regu ations, sufficient

access for safe maintenance (recommended on

an annua basis), or remova fo owing insta a-

tion,

MUST be provided for this product.

We

recommend that a c earance of at east 150mm

is avai ab e on each side of the cabinet to a ow

access to the motors.

See dimensions diagram.

•Fire Dampers must be fitted to duct work at appropriate ocations in accordance with Bui ding Regu ations

• F ue gases from fue -burning equipment must not be drawn into a iving area. If any room from which air

is extracted contains a fue burning app iance, such as a centra heating boi er, then its f ue must be of

the sea ed or ba anced f ue type, or a owance must be made for an adequate supp y of air into the room.

•The unit must NOT be insta ed:

- where there is excessive oi or grease

- where there are hazardous gases, iquids or vapours that are f ammab e or corrosive

- in ambient temperatures above 50ºC or ower than 5ºC (-28ºC using pre-heater)

- in humidity eve s above 90% or in a wet environment

• Where possib e the unit shou d NOT be insta ed direct y above a bedroom or iving room.

•The condensation drain MUST be fitted and if insu ated, use the equiva ent of at east 25mm of insu ating

materia with a therma conductivity of 0.04 W/(mK)

•Care shou d be taken to ensure that ducting is free from b ockages before switching on the unit as this may

inva idate your guarantee

•Externa gri es shou d be ocated a minimum of 600mm from any f ue out et in accordance with a

Regu ations

•The unit must be connected to a 230v-240v, 50Hz sing e phase e ectrica supp y.

•A trip e po e iso ation switch with contact separation of at east 3mm must be used to connect the app iance

to the fixed wiring when using the Switched Live.

• The product shou d on y be connected to the mains e ectricity supp y or e ectrica out et if:

- your e ectrica vo tage and frequency correspond to those shown on the rating abe .

- the capacity of your e ectricity supp y is sufficient y powerfu to operate the product at its

maximum power.

• If one of the spigots is not connected to ducting a safety gri e MUST be fitted to that spigot, so that it is

impossib e for any moving part to be touched.

Insta ation of the app iance MUST be carried out by a qua ified and suitab y competent person and shou d be

carried out in c ean, dry conditions where dust and humidity are at minima eve s. The unit is not suitab e for

insta ation to the exterior of the dwe ing.

Transportation, packaging and storage prior to insta ation

• Care shou d be taken when transporting the unit. Dropping or knocking wi damage the inner workings

of the unit.

• The unit shou d a ways be stored in a c ean, dry environment.

• Remove a packaging before insta ation.

Pre-inspection

• Inspect the unit and e ectrica supp y cord for any damage (damage must be repaired by a suitab y

qua ified and competent person.)

Page 3

Duct and Duct Connections (refer to design drawing)

• 4 x 204mmx 60mm spigots are provided for the connection of ducting. These are c ear y marked for cor-

rect connection of the supp y and exhaust ducts.

• Where ducting is insta ed in an unheated space, a of the ducts shou d be insu ated. Where ducting is in

sta ed in a heated space, on y the co d ducts shou d be insu ated. i.e. the supp y duct from outside and the ex-

tract duct from the unit to the outside.

• The duct ayout must be designed to suit the requirements of the venti ation/recovery system and bui ding ay-

out. If the ducting passes through a fire wa /barrier, suitab e fire dampers must be insta ed.

• Where rigid duct is used, it shou d be insta ed using the east number of fittings to minimise air f ow resist-

ance. Where possib e, fina connection to the gri es and unit shou d be made with a f exib e connection.

• Where f exib e ducts are used, ensure that:

- duct runs are kept as short as possib e

- the duct is stretched so that it is smooth and straight

- where bends are necessary, they have arge radii (ie avoid sharp bends)

- the duct is not crushed if in a restricted area

Condensation

(The unit may sometimes produce condensation which must be drained away. A 15mm dia pipe connection is

provided on this unit).

•A 15mm dia pipe must be fitted to the pipe connection. If any part of the condensate drain is in an

unheated space it MUST be insu ated with the equiva ent of at east 25mm of insu ating materia with a

therma conductivity of 0.04 W/mK.

•The pipe must drain into the norma househo d drainage system.

•The drain must incorporate a wet or dry trap to prevent air penetration.

•The unit must be ti ted towards the side carrying the condensation exit point. It shou d be insta ed

horizonta y with a 3º ti t towards the condensation drain used (equiva ent of raising the opposite end by

approximate y 25mm).

•The drainage pipe must have a continuous fa from the unit to the drainage co ection point.

E ectrica Connection

WARNING: these app iances must be earthed and a wiring must conform to current IEE Regu ations and a ap-

p icab e standards and Bui ding Regu ations.

• The unit is suitab e for 230V, 50Hz Sing e phase supp y.

• The unit is supp ied with:

- A mains rated 4 core f exib e cord (b ack, brown, grey and green/ye ow) and 2 core 0-10v cab es for purge

switching, or an externa connector box.

Cab es for any other externa device wi be provided and abe ed on request

• A trip e po e iso ation switch with contact separation of at east 3mm must be used to connect the app iance to the

fixed wiring when using the Switched Live.

• Boost contro s must not be ocated within 1 metre of a cooker or where they may be affected by excessive heat or

moisture.

• Boost and other externa contro s shou d be c ear y identified and convenient y ocated.

• The boost faci ity can be activated by a switched ive connection (in addition to the permanent supp y ive). The

switched ive can be operated by a variety of externa devices, inc uding:

- PIRFF (passive infra red)*

- DRH240 (dynamic remote humidistat)*

- THM (thermostat)*

- a ight switch (if more than one ight switch is used, each one must be a doub e po e switch)

- a remote switch/pu cord

or via LCD contro

(*PIRFF, DRH240 and THM may have integra over-run timer which contro s the ength of time that the fan wi

continue to operate at its boost speed after the boost has been switched off.)

Page 4