2

Contents

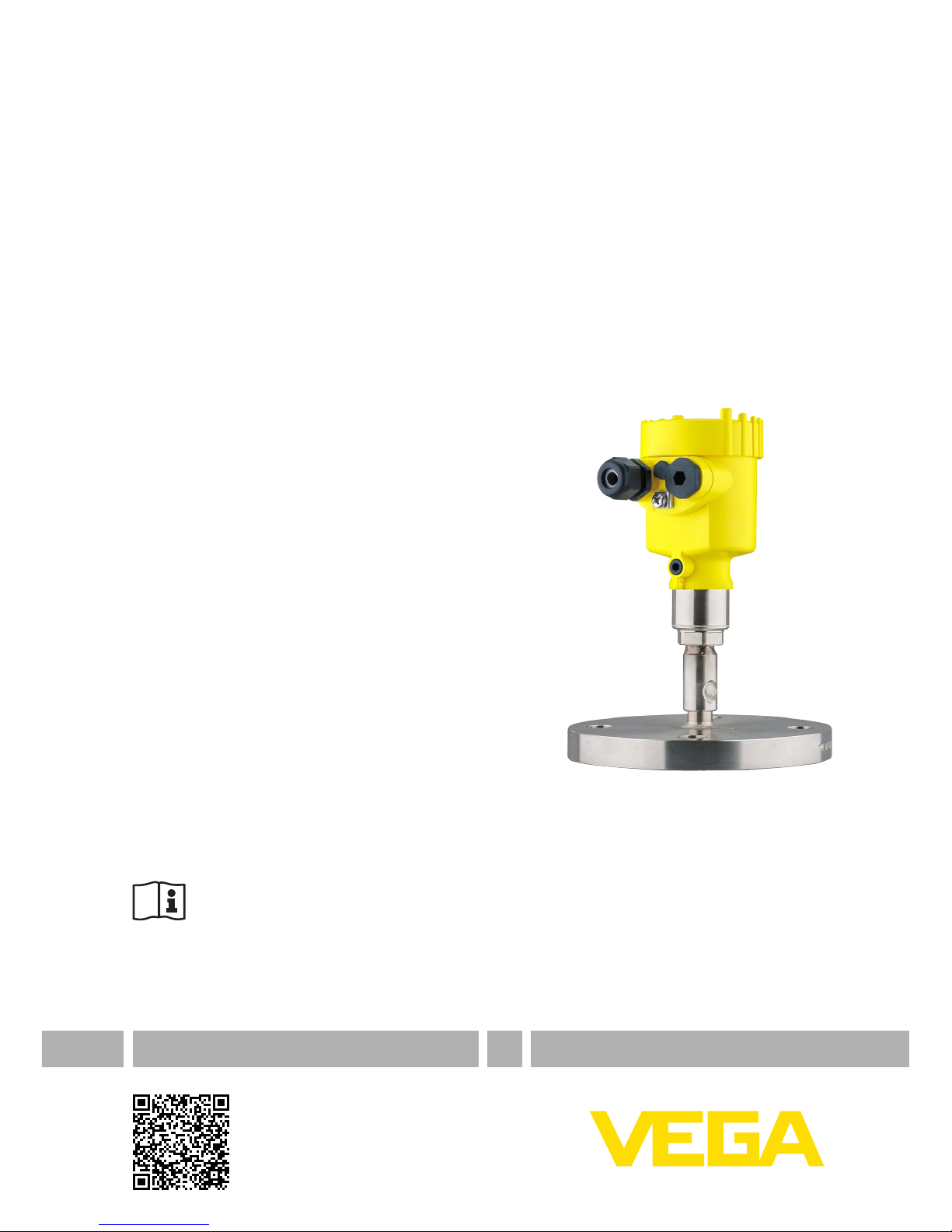

VEGABAR 81 • Probus PA

45020-EN-170522

Contents

1 About this document

1.1 Function ........................................................................................................................... 4

1.2 Target group ..................................................................................................................... 4

1.3 Symbols used................................................................................................................... 4

2 For your safety

2.1 Authorised personnel ....................................................................................................... 5

2.2 Appropriate use................................................................................................................ 5

2.3 Warning about incorrect use............................................................................................. 5

2.4 General safety instructions............................................................................................... 5

2.5 EU conformity................................................................................................................... 6

2.6 Permissible process pressure .......................................................................................... 6

2.7 NAMUR recommendations .............................................................................................. 6

2.8 Installation and operation in the USA and Canada ........................................................... 6

2.9 Environmental instructions ............................................................................................... 6

3 Product description

3.1 Conguration.................................................................................................................... 8

3.2 Principle of operation........................................................................................................ 9

3.3 Supplementary cleaning procedures.............................................................................. 12

3.4 Packaging, transport and storage................................................................................... 13

3.5 Accessories and replacement parts ............................................................................... 13

4 Mounting

4.1 General instructions ....................................................................................................... 16

4.2 Ventilation and pressure compensation.......................................................................... 17

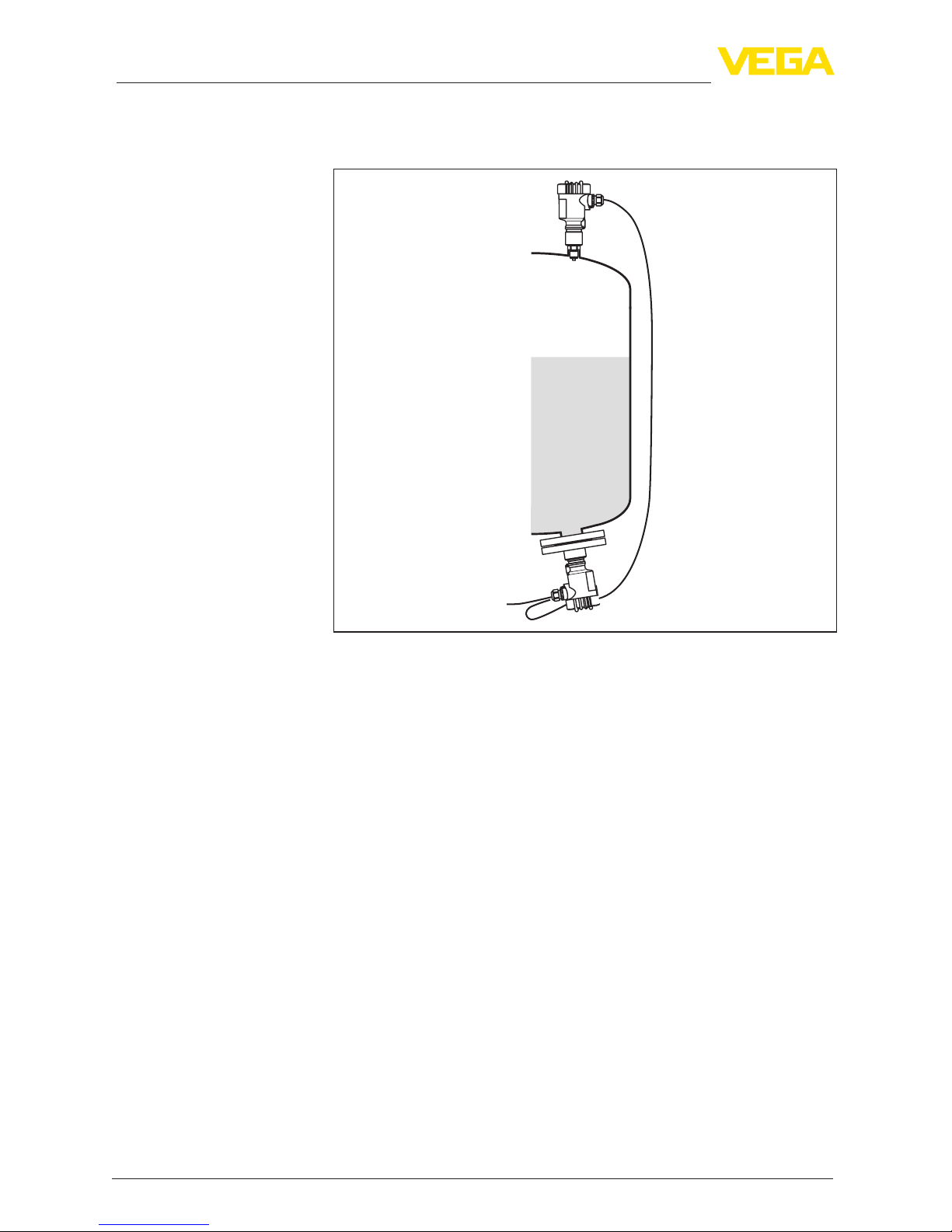

4.3 Process pressure measurement..................................................................................... 20

4.4 Level measurement........................................................................................................ 23

4.5 External housing ............................................................................................................ 24

5 Connecting to the bus system

5.1 Preparing the connection ............................................................................................... 25

5.2 Connecting..................................................................................................................... 26

5.3 Single chamber housing................................................................................................. 28

5.4 Double chamber housing ............................................................................................... 28

5.5 Ex-d double chamber housing........................................................................................ 29

5.6 Double chamber housing with VEGADIS-Adapter.......................................................... 30

5.7 Housing IP 66/IP 68 (1 bar) ............................................................................................ 31

5.8 External housing with version IP 68 (25 bar)................................................................... 32

5.9 Switch-on phase............................................................................................................. 33

6 Set up with the display and adjustment module

6.1 Insert display and adjustment module............................................................................ 35

6.2 Adjustment system......................................................................................................... 36

6.3 Measured value indication.............................................................................................. 38

6.4 Parameter adjustment - Quick setup .............................................................................. 38

6.5 Parameter adjustment - Extended adjustment................................................................ 39

6.6 Saving the parameterisation data................................................................................... 52

7 Setup with PACTware

7.1 Connect the PC.............................................................................................................. 53

7.2 Parameter adjustment .................................................................................................... 53