2

Contents

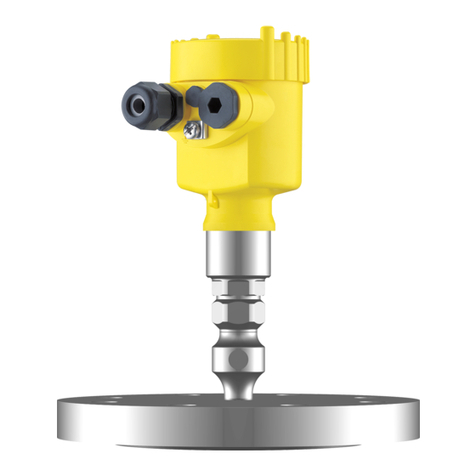

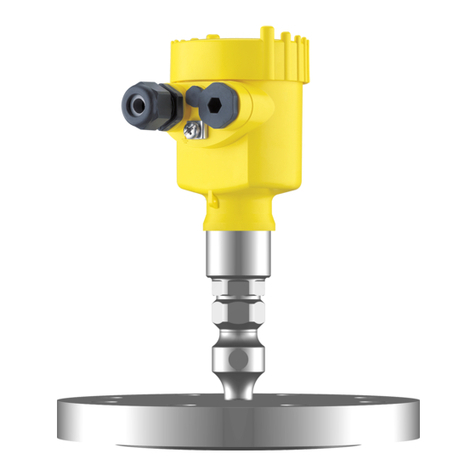

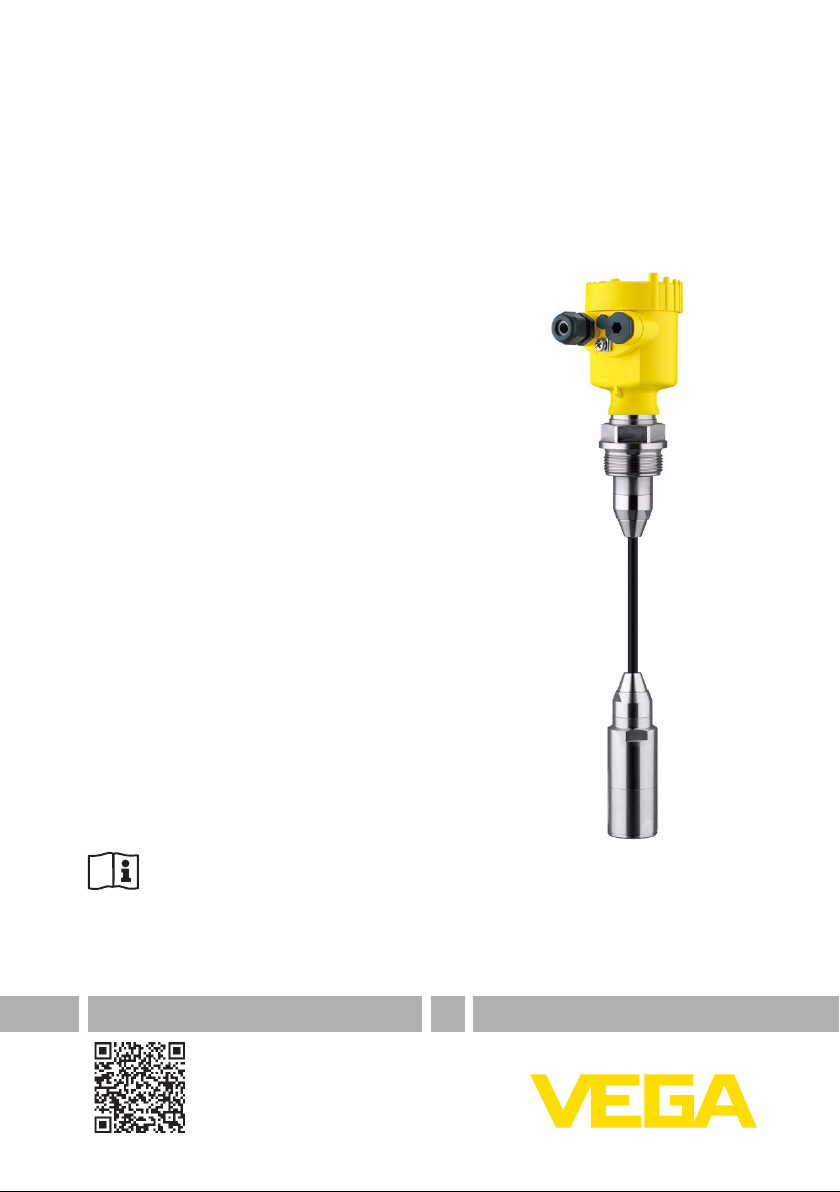

VEGABAR 86 • Probus PA

46322-EN-230914

Contents

1 For your safety ......................................................................................................................... 3

1.1 Authorised personnel ....................................................................................................... 3

1.2 Appropriate use................................................................................................................ 3

1.3 Warning about incorrect use............................................................................................. 3

1.4 General safety instructions............................................................................................... 3

1.5 Conformity........................................................................................................................ 3

1.6 NAMUR recommendations .............................................................................................. 4

1.7 Environmental instructions ............................................................................................... 4

2 Product description ................................................................................................................. 5

2.1 Conguration.................................................................................................................... 5

3 Mounting................................................................................................................................... 6

3.1 General instructions for use of the instrument .................................................................. 6

3.2 Ventilation and pressure compensation............................................................................ 6

4 Connecting to the bus system................................................................................................ 8

4.1 Connecting....................................................................................................................... 8

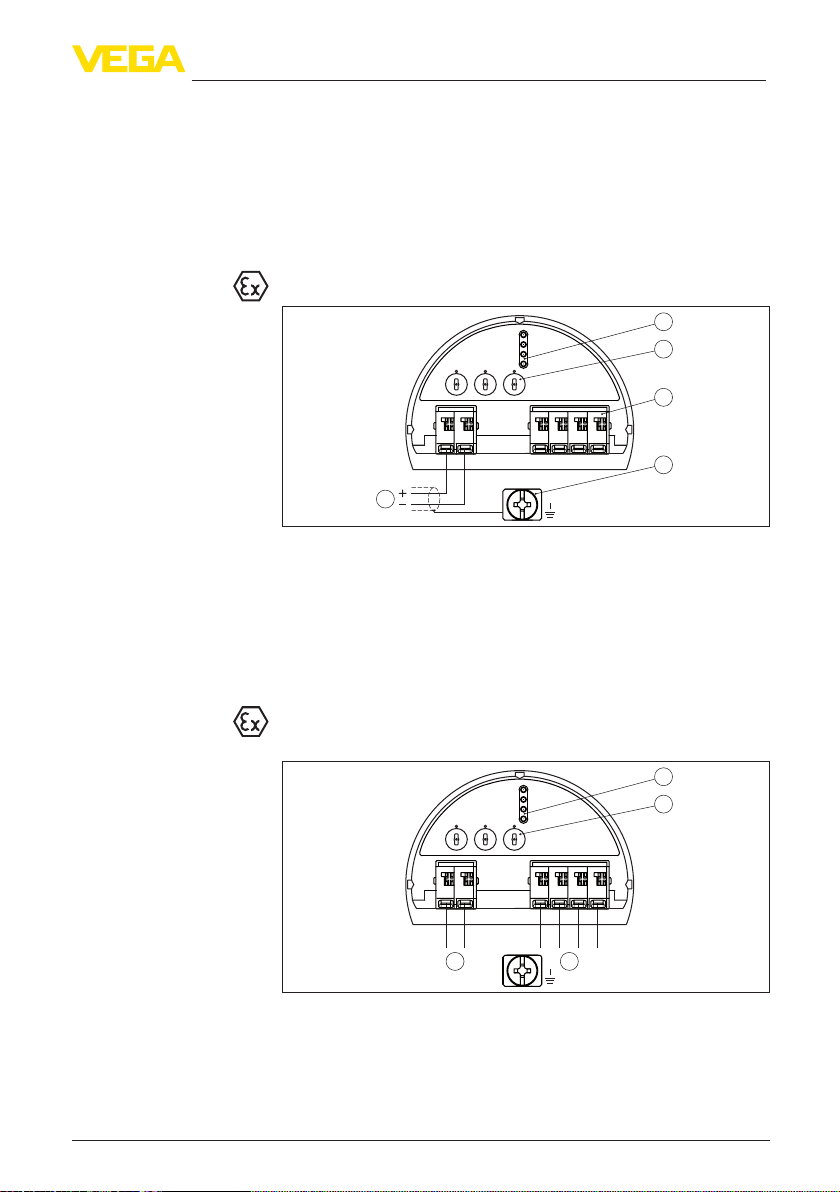

4.2 Single chamber housing................................................................................................... 9

4.3 Double chamber housing ................................................................................................. 9

5 Set up with the display and adjustment module ................................................................ 11

5.1 Insert display and adjustment module............................................................................ 11

5.2 Parameter adjustment - Quick setup .............................................................................. 12

5.3 Parameter adjustment - Extended adjustment................................................................ 14

5.4 Menu overview ............................................................................................................... 15

6 Set up with smartphone/tablet, PC/notebook via Bluetooth ............................................. 18

6.1 Preparations................................................................................................................... 18

6.2 Connecting..................................................................................................................... 19

6.3 Sensor parameter adjustment ........................................................................................ 19

7 Supplement ............................................................................................................................ 21

7.1 Technical data ................................................................................................................ 21

Information:

This quick setup guide enables quick setup and commissioning of

your instrument.

You can nd supplementary information in the corresponding, more

detailed Operating Instructions Manual as well as the Safety Manual

that comes with instruments with SIL qualication. These manuals are

available on our homepage.

Operating instructions VEGABAR 86 - Probus PA: Document-

ID 45042

Editing status of the quick setup guide: 2023-09-06