2-3

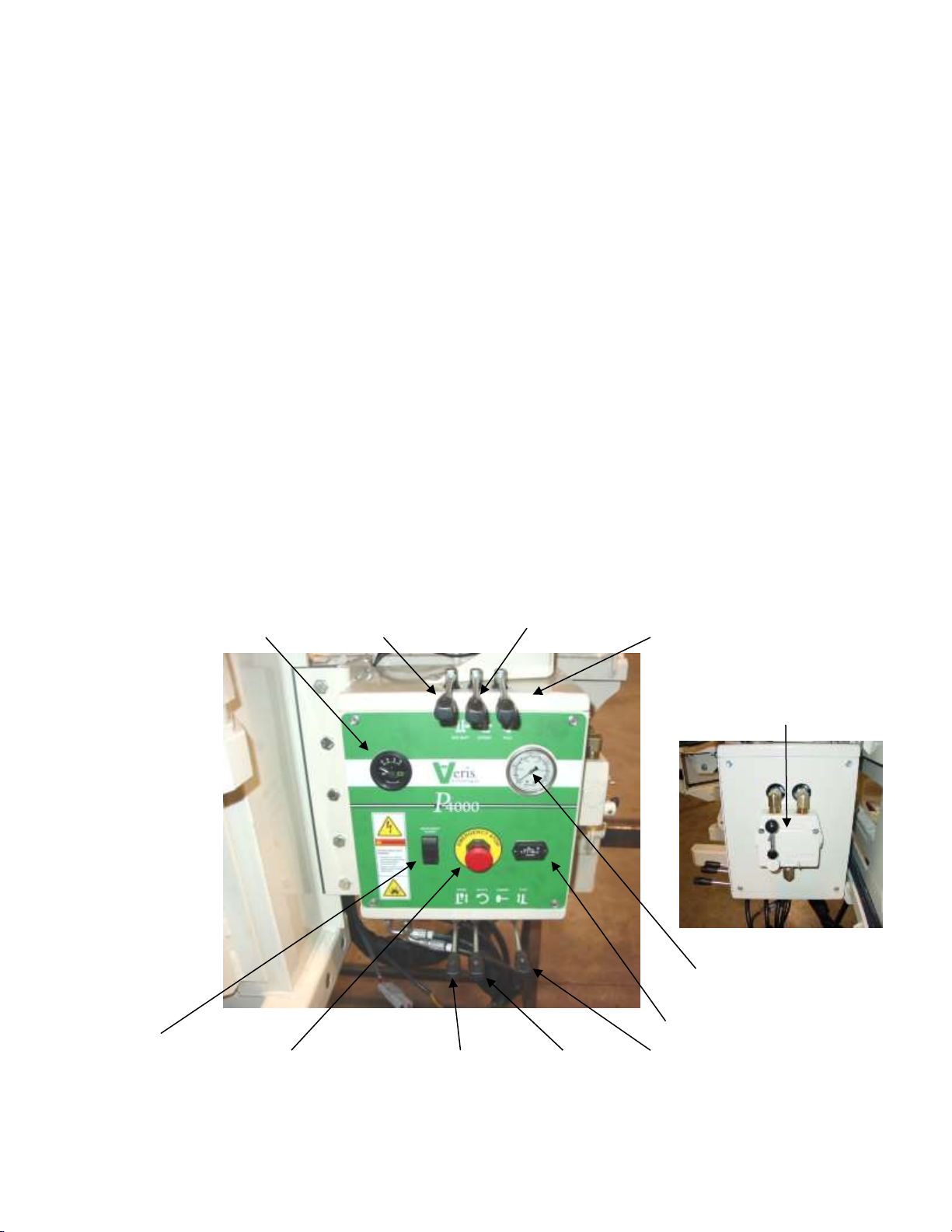

Important! Read the following SAFETY PROCEDURES before operating the Veris

P4000

• Probing into buried electrical, gas, sewer, communication and other utilities can cause

death, serious injury, and significant property loss. Utilize ‘call before you dig’ services.

• Pinch point hazard: to prevent injury, stand clear when raising or lowering any part of

the Veris P4000.

• Install all transport locks before transporting or working underneath.

• Detach and store implements in an area where children normally do not play. Secure

implement by using blocks and supports.

• Keep feet clear of foot and probe when lowering.

• Do not probe where utility lines may be present. Use ‘Call Before You Dig’ services.

• Use paper or cardboard, NOT BODY PARTS, to check for suspected leaks.

• Wear protective gloves and safety glasses or goggles when working with hydraulic and

high-pressure wash systems.

• If an accident occurs, see a doctor immediately. Any fluid injected into the skin must

be surgically removed within a few hours or gangrene may result.

• Read Operations Manual before operating machine

• Review safety instructions with operators before operating machine and at least

annually

• Riders obstruct the operator’s view. They could be struck by foreign objects or

thrown from the machine.

• Never allow children to operate equipment.

• To prevent possible electrical shock, or damage to the instrument, do not connect to

any power source greater than twelve (12) volts DC.

• Do not grease or oil implement while it is in operation.

• Disconnect battery ground cable (-) before servicing or adjusting electrical systems or

before welding on implement.

• Remove buildup of mud, oil or debris.

• Be prepared if a fire starts

• Keep a first aid kit and fire extinguisher handy.

• Be careful when touching the probe after use, the sapphire window gets hot.

Section 2