Contents

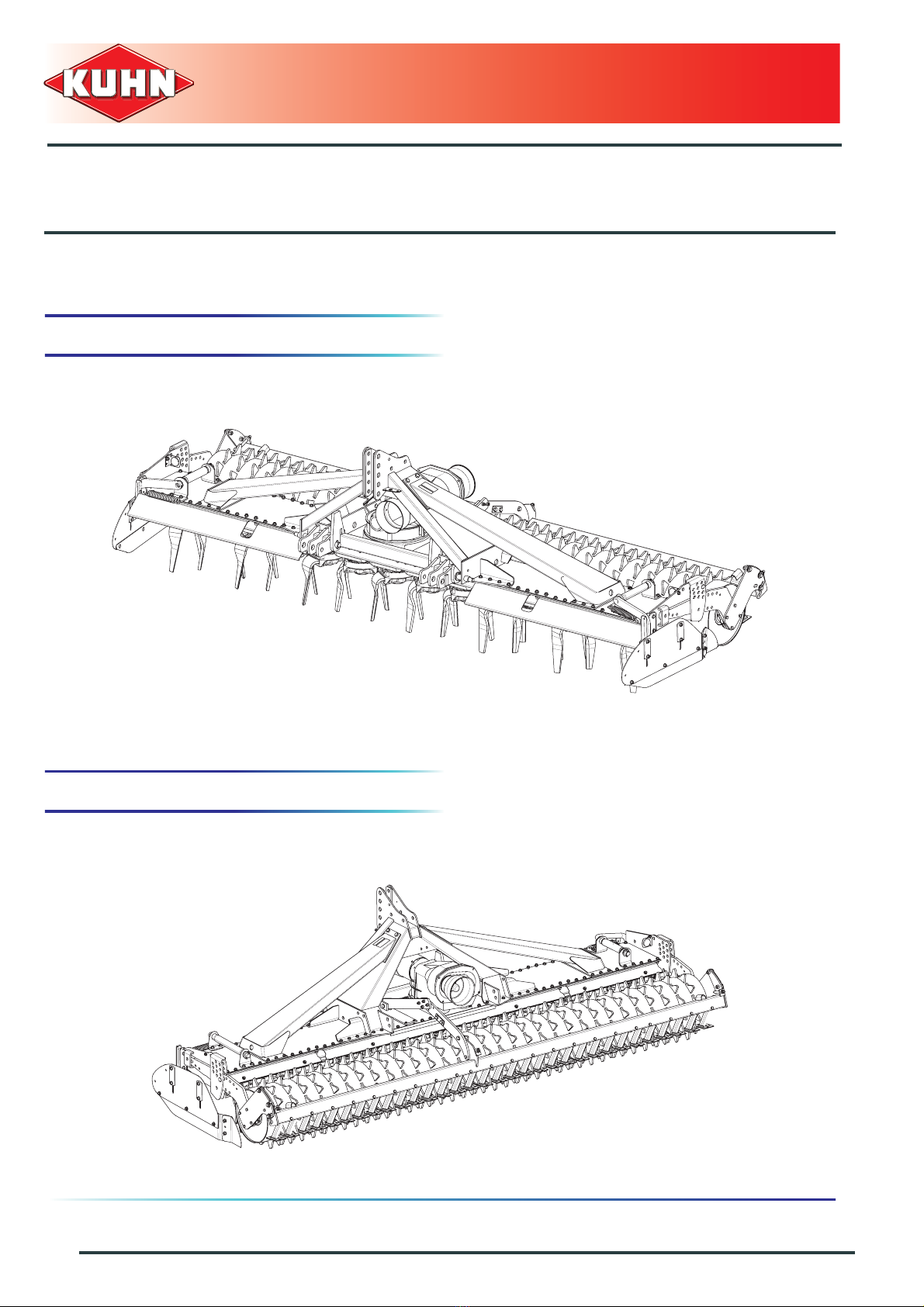

Power harrows

HR4004D - 4504D

3

Instructions for work................................................................................................... 45

Putting the machine into work position.......................................................................................45

Adjustments in working position..................................................................................................45

Machine use....................................................................................................................................46

Optional equipment.....................................................................................................48

Sets of gearwheels.........................................................................................................................48

Standard linkage ............................................................................................................................50

Hydraulic lift linkage......................................................................................................................51

Hydraulic lift linkage stroke limiters.............................................................................................56

High capacity hydraulic lift linkage ..............................................................................................57

Track eradicators............................................................................................................................62

Front or rear levelling bar..............................................................................................................64

Front semi-automatic linkage .......................................................................................................65

Adaptation parts for VENTA LC.....................................................................................................66

Adaptation parts for VENTA AL and VENTA TI............................................................................66

Adaptation parts for INTEGRA......................................................................................................67

Lengthened coupling yokes..........................................................................................................67

Maintenance and storage............................................................................................ 68

Frequency chart .............................................................................................................................68

Cleaning the machine....................................................................................................................69

Lubrication......................................................................................................................................71

Maintenance....................................................................................................................................74

Storage............................................................................................................................................82

Troubleshooting guide................................................................................................83

Appendix ...................................................................................................................... 85

Calculating the load on an axle.....................................................................................................85

Limited warranty.......................................................................................................... 91