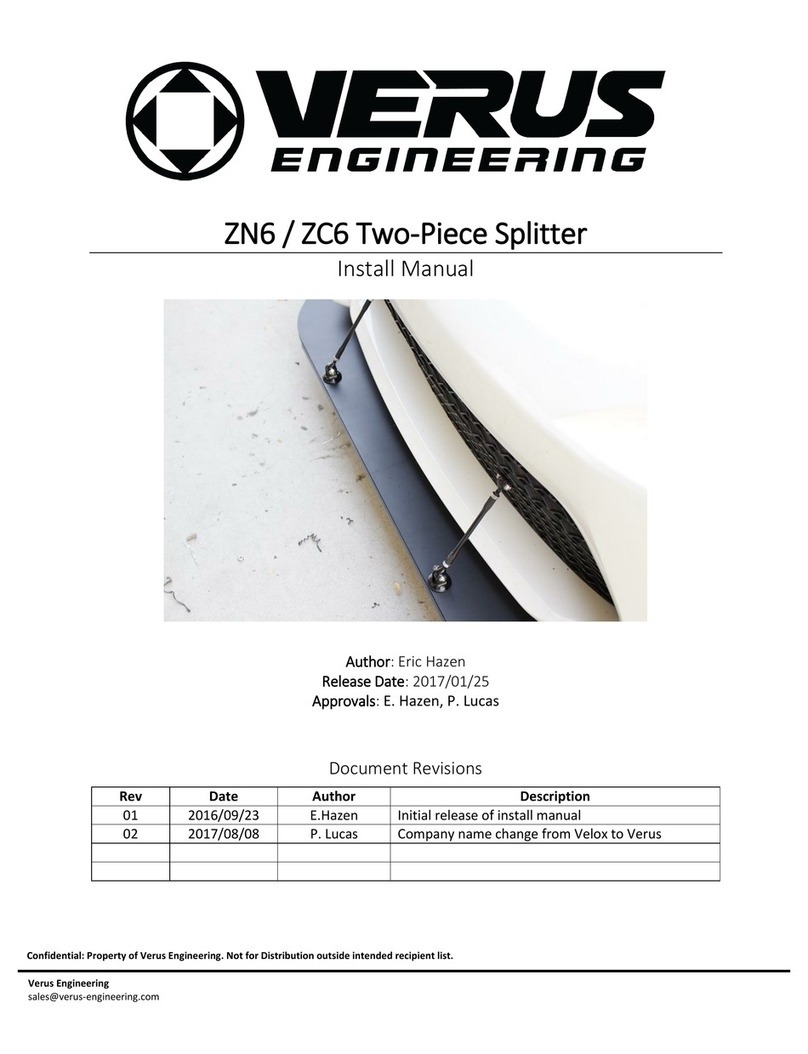

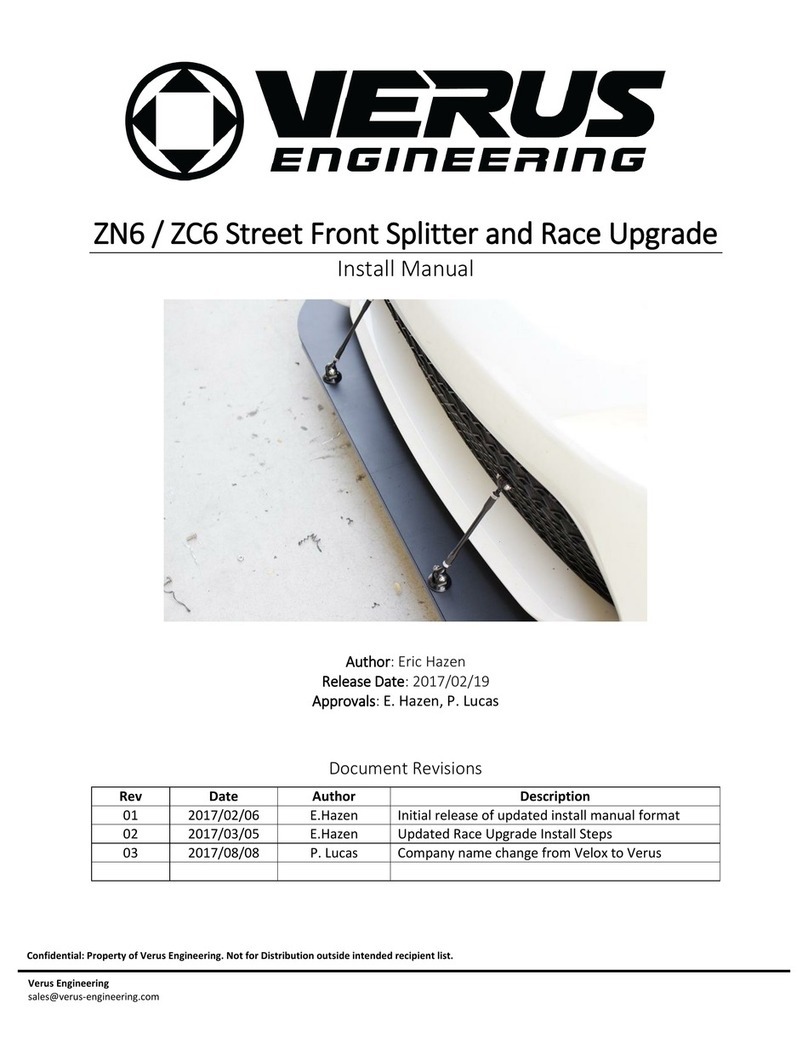

Verus Engineering ZN6 Manual

Other Verus Engineering Automobile Accessories manuals

Verus Engineering

Verus Engineering Dive Plane Manual

Verus Engineering

Verus Engineering ZN6 Manual

Verus Engineering

Verus Engineering ZN6 Manual

Verus Engineering

Verus Engineering A0158A User manual

Verus Engineering

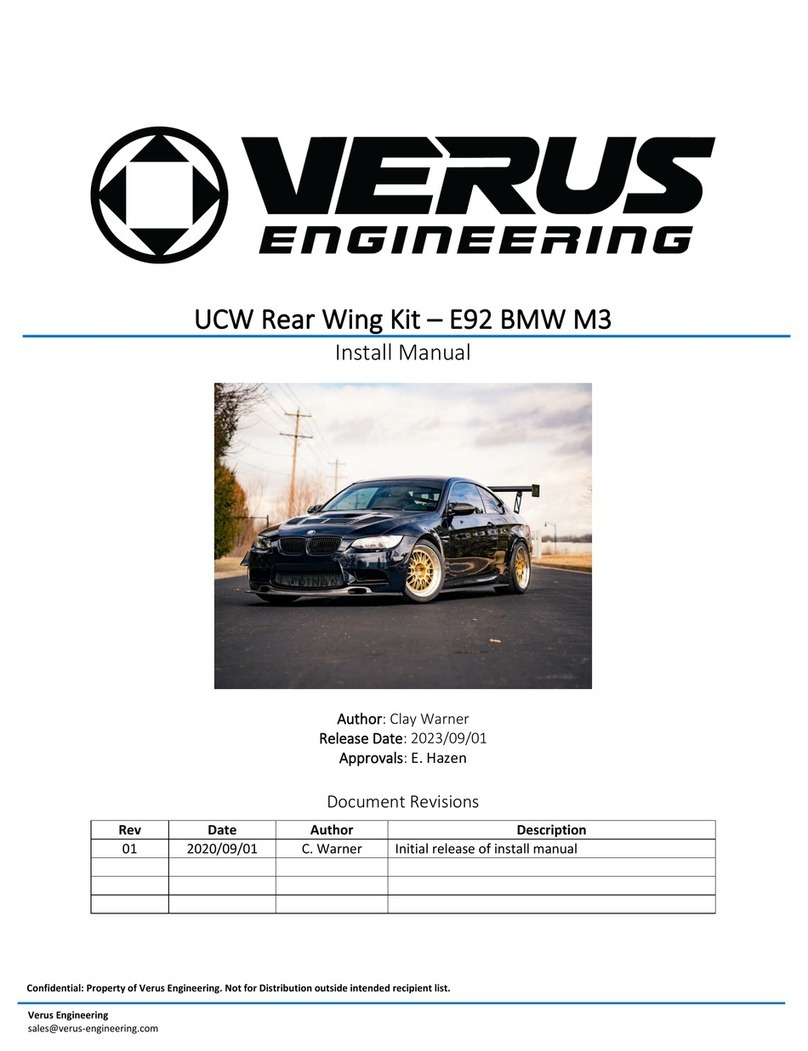

Verus Engineering UCW Rear Wing Kit Manual

Verus Engineering

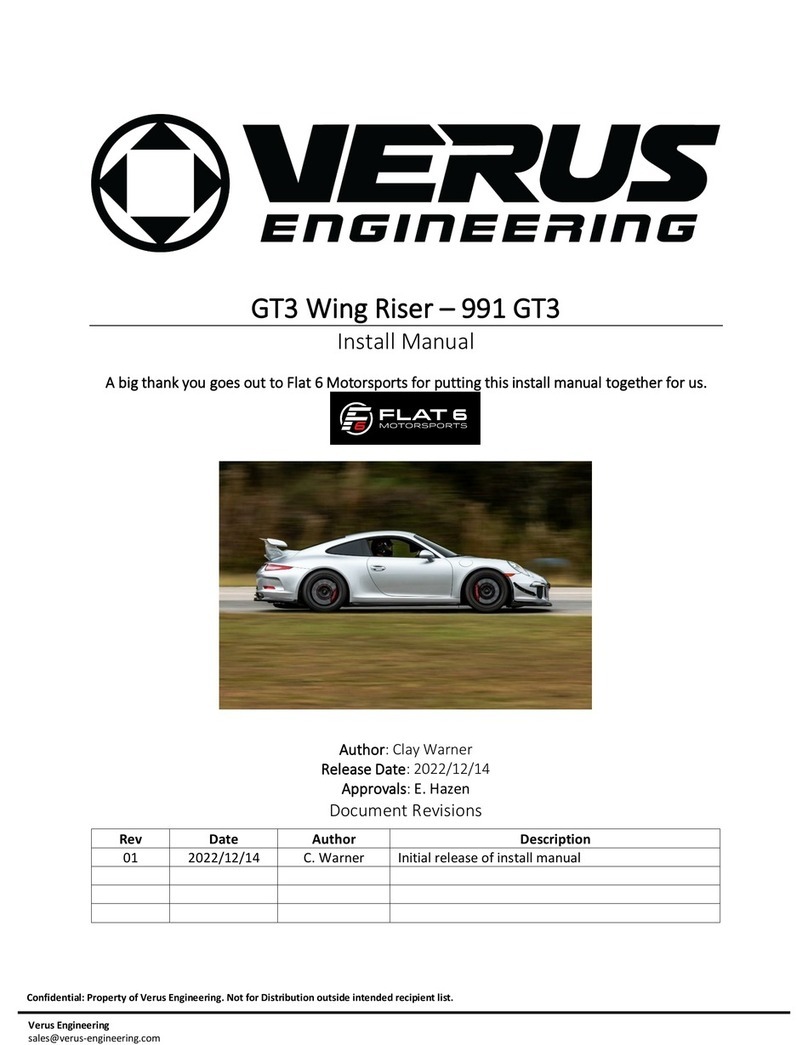

Verus Engineering Wing Riser 991 GT3 Manual

Verus Engineering

Verus Engineering A0105A Manual

Popular Automobile Accessories manuals by other brands

ULTIMATE SPEED

ULTIMATE SPEED 279746 Assembly and Safety Advice

SSV Works

SSV Works DF-F65 manual

ULTIMATE SPEED

ULTIMATE SPEED CARBON Assembly and Safety Advice

Witter

Witter F174 Fitting instructions

WeatherTech

WeatherTech No-Drill installation instructions

TAUBENREUTHER

TAUBENREUTHER 1-336050 Installation instruction