VWS, Manual

Copyright 2016Vestil Manufacturing Corp. Page 8 of 10

Maintenance and Inspections:

Only trained, authorized persons should inspect of and maintain this device. The end-user is responsible for

ensuring that the lifter is properly inspected and maintained.

RECORD OF SATISFACTORY CONDITION (THE “RECORD”)

Record the condition of the stacker before putting it into service. Thoroughly photograph the unit from multiple

angles so that all operating mechanisms are clearly visible. Take close range photographs of the labeling applied to

the stacker. Raise and lower the forks. Describe the operation of the winch. Describe sounds heard as the forks

rises and descends. Include detailed descriptions about the frame, winch, rollers, wheels, casters, carriage, mast

rollers, and the lifting mechanisms (winch, cable, and pulleys). How much effort is required to turn the winch?

Collate all photographs and writings into a single file. Give the file a name that clearly identifies it. This file is a

record of the unit in satisfactory condition. Compare all inspection results to the record to determine whether the

truck is in satisfactory condition. Purely cosmetic changes, like damaged paint/powder coat are not changes from

satisfactory condition. However, touch-up paint to be applied to all affected areas as soon as damage occurs.

INSPECTIONS & MAINTENANCE

Regular inspections and maintenance are necessary to keep the stacker in normal condition. Compare the results of

each inspection to the Record to determine whether the unit is satisfactory condition or requires repairs or

replacement parts. If you are uncertain whether a part requires repair or replacement, contact Technical Service for

assistance.

•Periodically lubricate moving parts.

•Keep the product clean and dry.

•Only use manufacturer-approved replacement parts.

At

least once per week, inspect the following components:

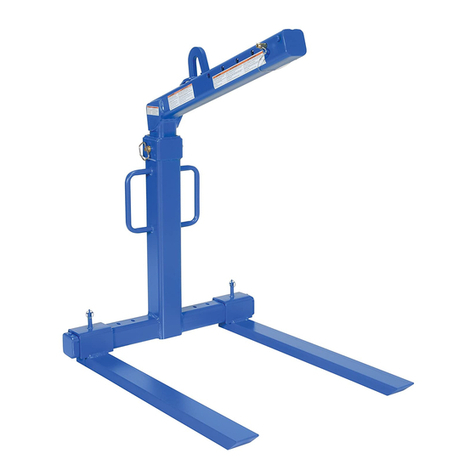

1. Winch, winch mounting bracket, cable, carriage rollers, and pulley.Cycle the forks up and down. Listen for

unusual noises and watch for binding or rough movement as the carriage moves. If the carriage does not move

smoothly or makes noise as it moves up or down the upright, apply a silicon wax or silicon spray to the inside

of the mast frame. Examine the winch. Make sure that the spool is intact and rotates smoothly when the

handle is turned. Inspect the mounting bracket. The winch should be solidly attached to the bracket. Tighten all

loose fasteners. Lower the carriage and examine the cable for reeving, stretching, thinning portions, etc.

Confirm that the pulley rotates freely and is securely fastened to the mast.

2. Frame (mast, base): Examine the frame members for damaged welds, severe rusting, cracks, bends, etc.

Remove rust with steel wool. Clean the affected areas and apply touch-up paint.

3.Wheels, rollers, and casters: Check each wheel, caster, and roller for wobbliness, damage, and severe wear. All

should roll smoothly. Clean them to remove debris from the surfaces, if necessary.

4.Hardware: Examine the pins, bolts, nuts, etc. Tighten loose fasteners. Replace all damaged fasteners.

Maintenance: Implement a maintenance program to ensure that the lifter functions normally for as long as possible.

Page 9 of ANSI/ITSDF standard B56.10-2006, “Manually propelled high lift industrial trucks”, describes recommended

maintenance procedures. A copy of the standard is downloadable for free from the ITSDF website (www.itsdf.org).

Apply t

hose recommendations in conjunction with the following steps.

1. Tag the lifter, “Out of Service.”

2. Inspect the lifter as described above. If deformity, corrosion, rusting, or excessive wear of structural members is

present, permanently remove the lifter from service.

3. Remove any dirt or other matter from the cable and pulleys and other lifter surfaces.

4. Perform all other necessary adjustments and/or repairs. DO NOT modify the lifter.

5. Make a dated record of the repairs, adjustments and/or replacements made.