Table of Contents 2/4/2022 HLD MANUAL

Table of Contents Copyright 2010 Vestil Manufacturing Corp. Page 7 of 19

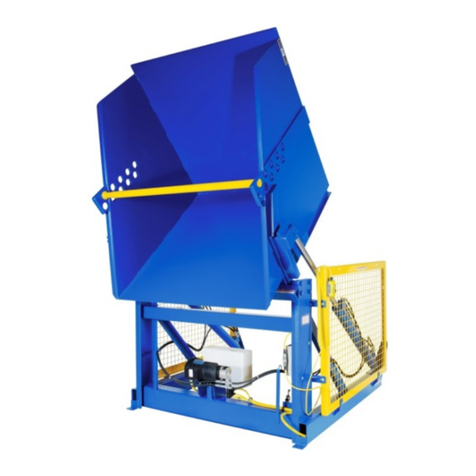

POWER UNIT OPERATION

An electric motor directly coupled to a gear pump pressurizes the hydraulic system. Fluid pressure

causes the lift and tilt cylinders to extend and retract. Cylinder movement performs the work required to

raise and lower, and tilt and un-tilt the chute. A hydraulic manifold bolted directly onto the gear pump

houses the hydraulic control components; each component is rated for 3,000psi working pressure.

Important components of the power unit include:

•Electric motor: Motor voltage and phase (single or 3-phase) was selected at the time this unit was

ordered. Every motor is dual-voltage capable.

•Gear pump: The pump shaft is coupled directly to the shaft of the electric motor. Several

displacements are available that vary with the horsepower of the motor selected.

•Check valve: Prevents backflow of fluid through the pump. Allows the chute maintain position while the

motor is inactive (no signal from the handheld controller).

•Pressure relief valve: While open, the valve provides a path for oil to return to the reservoir. The valve

opens if hydraulic pressure exceeds 3,000psi.

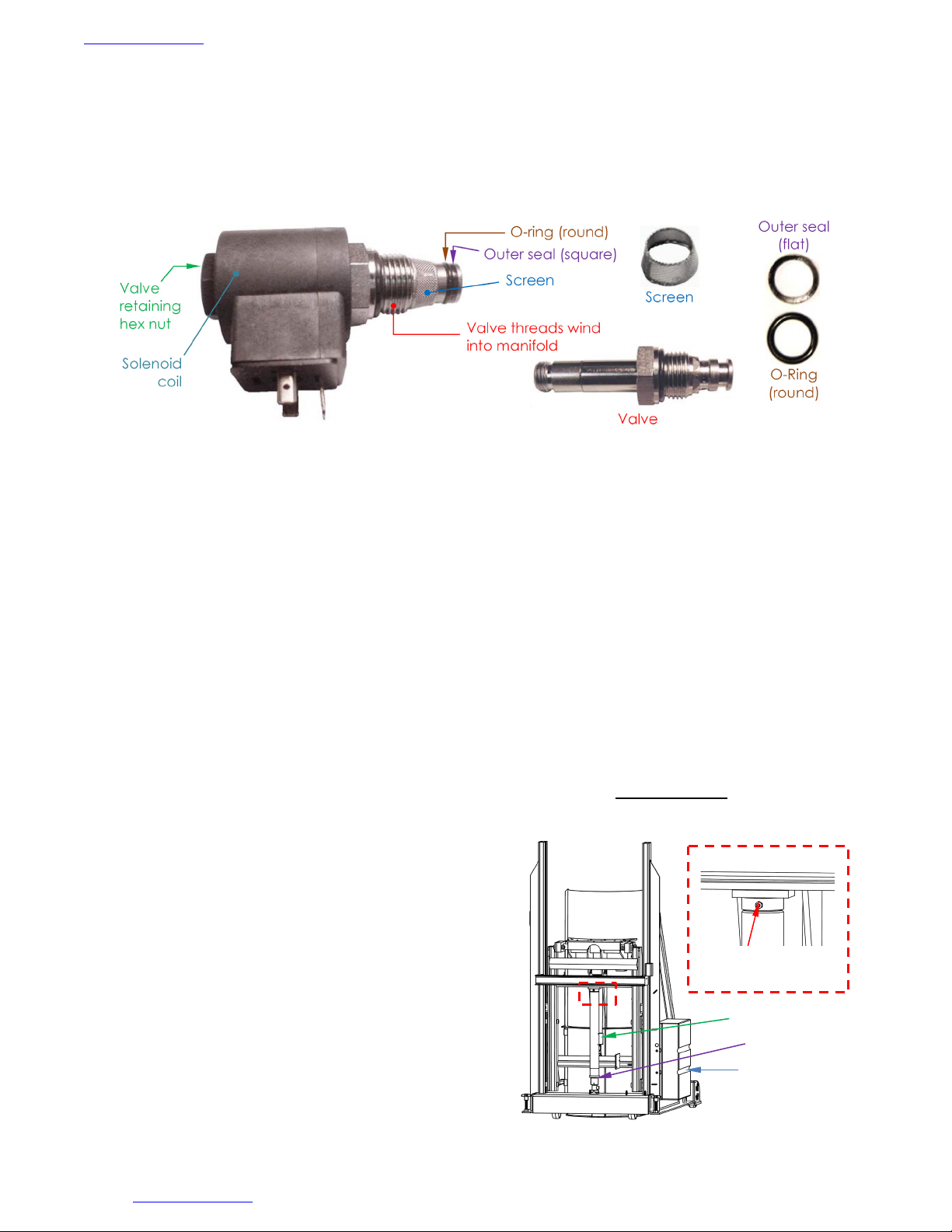

•Lowering solenoid valve: An electrically-operated cartridge valve with an integral screen to keep

contaminants from entering the valve.

•Pressure compensated flow control spool: The spool is located beneath the lowering valve. It governs

the retraction rate of the cylinders and, therefore, the lowering rate of the drum chute. This component

allows the chute to lower at a constant rate regardless of the weight of the drum and its contents.

•Hydraulic cylinders: Displacement style cylinders lift and tilt the chute. Each cylinder includes an integral

bleeder valve located at top end. The valve is used to remove air from the hydraulic system.

•Velocity fuse: Safety device that prevents the flow of oil out of a cylinder if system pressure is disrupted.

A cylinder cannot retract until its velocity fuse is deactivated, i.e. by repressuring the system.

•Hydraulic fluid: HO150 hydraulic fluid. To replenish the fluid, add anti-wear hydraulic fluid with a viscosity

grade of 150 SUS at 100°F (ISO 32 @ 40°C) like AW-32 or Dexron transmission fluid.

SEQUENCE OF OPERATION

Elevate the chute by pressing the RAISE LIFT button of the 4-point controller button. See FIGS. 3A & 3B,

p. 5. In response to the signal from the controller, the motor turns and spins the gear pump. Oil flows out

of the reservoir, through the suction filter and into the pump.

•The pump propels oil through the check valve to the lift cylinder (99-021-912-001 or 99-021-913-001 in the

applicable exploded view).

•An upper travel limit switch turns off the motor when the chute reaches a preset elevation.

•Releasing the RAISE LIFT button immediately halts chute movement. The chute maintains position until a

control button is pressed.

To lower the chute, press the LOWER LIFT button.

•Lowering valve opens and allows oil from the cylinders to bypass the check valve. Oil flows out of the

cylinders to the reservoir through return hoses.

•Releasing the LOWER LIFT button during operation causes all downward movement to stop. The chute

will remain in the same position until a control button is pressed.

To tilt the chute, press the RAISE TILT button. The motor turns and spins the gear pump. Oil is drawn from

the reservoir, through the suction filter and into the pump.

•Pressurized oil flows through the check valve to the tilt cylinder (99-021-909-001 in FIGS. 9-12).

•Releasing the RAISE TILT button during operation immediately halts all chute movement.

•Additionally, an upper travel limit switch automatically turns off the motor when the chute reaches a

preset 40° (mobile units) or 45° (stationary/bolt-down) tilt angle.

To un-tilt the chute, press the “LOWER TILT” button.

•Lowering valve opens and bypasses the check valve, which allows oil in the cylinders to flow to the

reservoir (through return hoses).

•Releasing the LOWER TILT button during operation causes all chute rotation to stop.The chute will

remain in the same position until you press the LOWER TILT button again and allow it to rotate back to

the vertical orientation.

OPERATION ISSUES AND SOLUTIONS

If the chute slowly un-tilts without pressing the LOWER TILT button, or if the chute lowers without pressing

the LOWER LIFT button, the lowering cartridge valve of the affected cylinder should be removed,

inspected, and cleaned.

1. Press the LOWER TILT button until the chute is in home position (lower the chute completely).