PART NO. 91025

It is essential that you and any other operator of this product read and understand

contents of this manual efore installing and using this product.

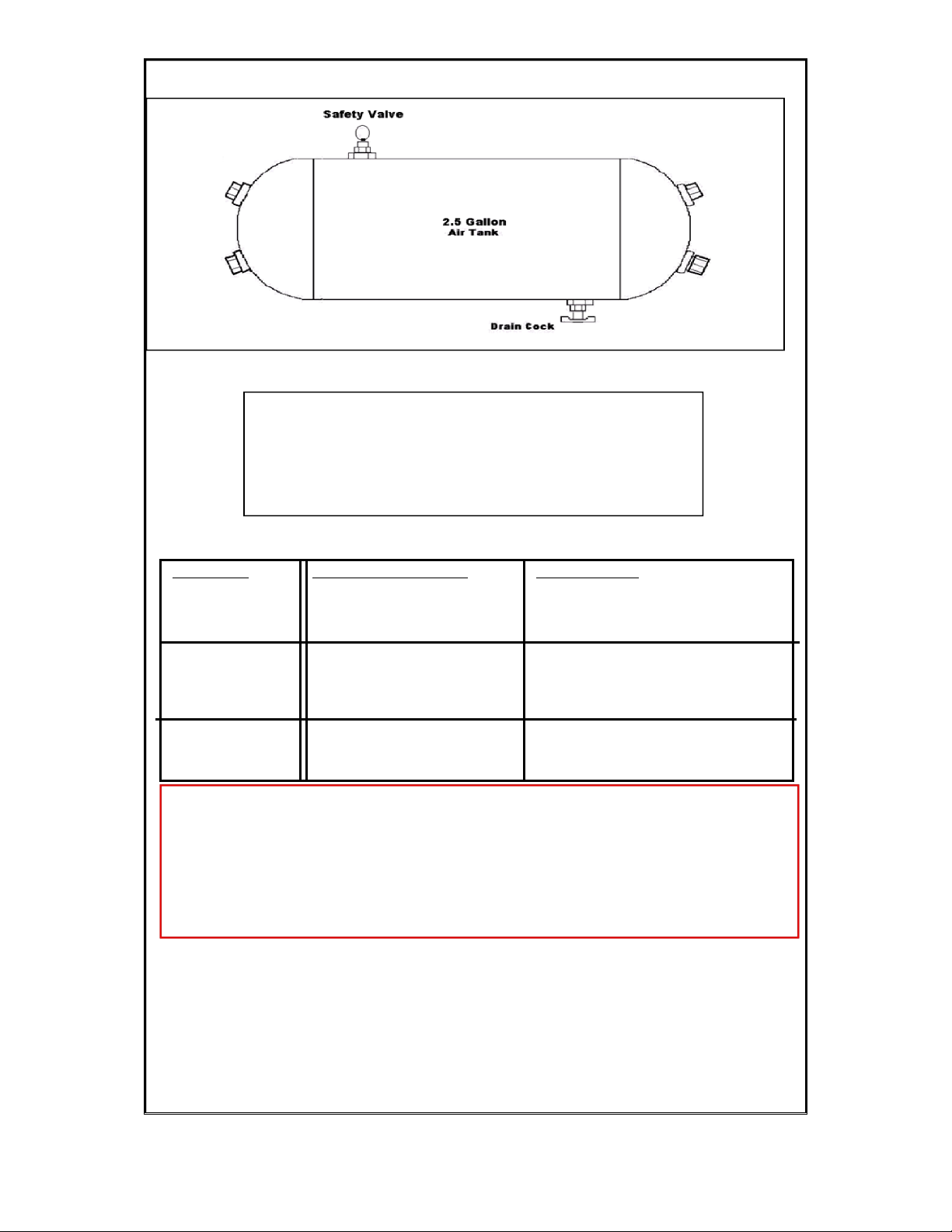

Your air tank comes with six NPT port openings to allow installation in many positions

on your vehicle. To insure safe and trou le-free use of your air tank, we strongly

recommend that you install a drain cock and a safety pressure relief valve on your air

tank. We recommend use of our Tank Port Fittings Kit (Part No. 90005), which comes

with a drain cock, a 175psi safety valve, and three plugs.

IMPORTANT:

a. Tank is rated for 150 PSI maximum working pressure. Do not overfill. Overfilling

may result in death or serious injury.

. Tank is not to e used as a reathing device.

c. Always wear ANSI approved safety glasses when operating air tank.

d. Bleed pressure from tank after each use, and efore servicing or adding

attachments.

e. Use only attachments or tools rated for 150 PSI working pressure or less.

CAUTION! DO NOT PRESSURIZE YOUR TANK UNTIL YOU HAVE INTALLED ALL

NECESSARY PORT FITTINGS AND ACCESSORIES.

a. Apply sealant to threads of fittings prior to assem ly and tighten each part with a

wrench.

. Do not over tighten if your port fittings are made from rass, since rass threads

can e stripped. The fittings need to e only air tight.

c. Always release air from tank efore servicing or repairs.

WARNING: DRAIN TANK AFTER EACH USE. FAILURE TO DRAIN TANK AND REMOVE

CONDENSATION WILL CAUSE TANK TO RUST PREMATURELY.

a. To remove any accumulated condensation inside the tank, leed pressure from

tank until pressure is approximately 5psi to 20 psi.

. Drain water from tank y opening the drain cock drain valve.

c. If drain cock valve is plugged, release all air pressure from tank, remove drain valve

and clean, then reinstall.

d. After water has een drained, close the drain cock.

IMPORTANT: Please o serve air tank’s Date of Manufacture (stamped on tank leg).

Replace air tank 2 to 5 years from date air tank was first used, or use the date of

manufacture as reference. Your adherence to air tank draining guidelines will determine

the replacement date of your air tank. RUSTED TANKS CAN FAIL CAUSING EXPLOSIONS

OR FATAL INJURIES. Discard tank immediately if tank is rusted.

NOTE: When using a safety pressure relief valve, point the safety pressure relief valve

away from your ody when releasing air. Use the pull ring on the safety relief valve; open

the relief valve to vent any pressure inside the tank efore attempting to service tank.

USER MANUAL