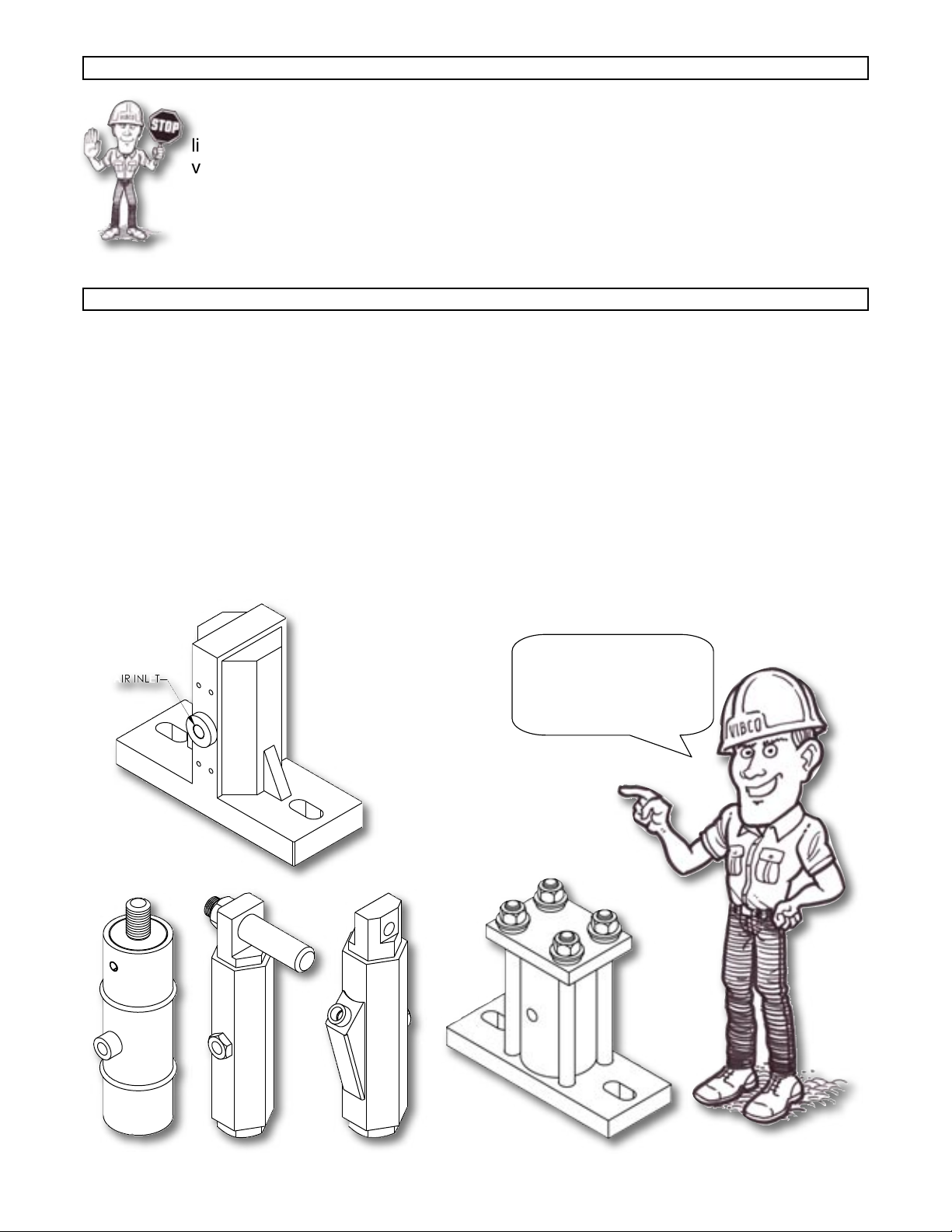

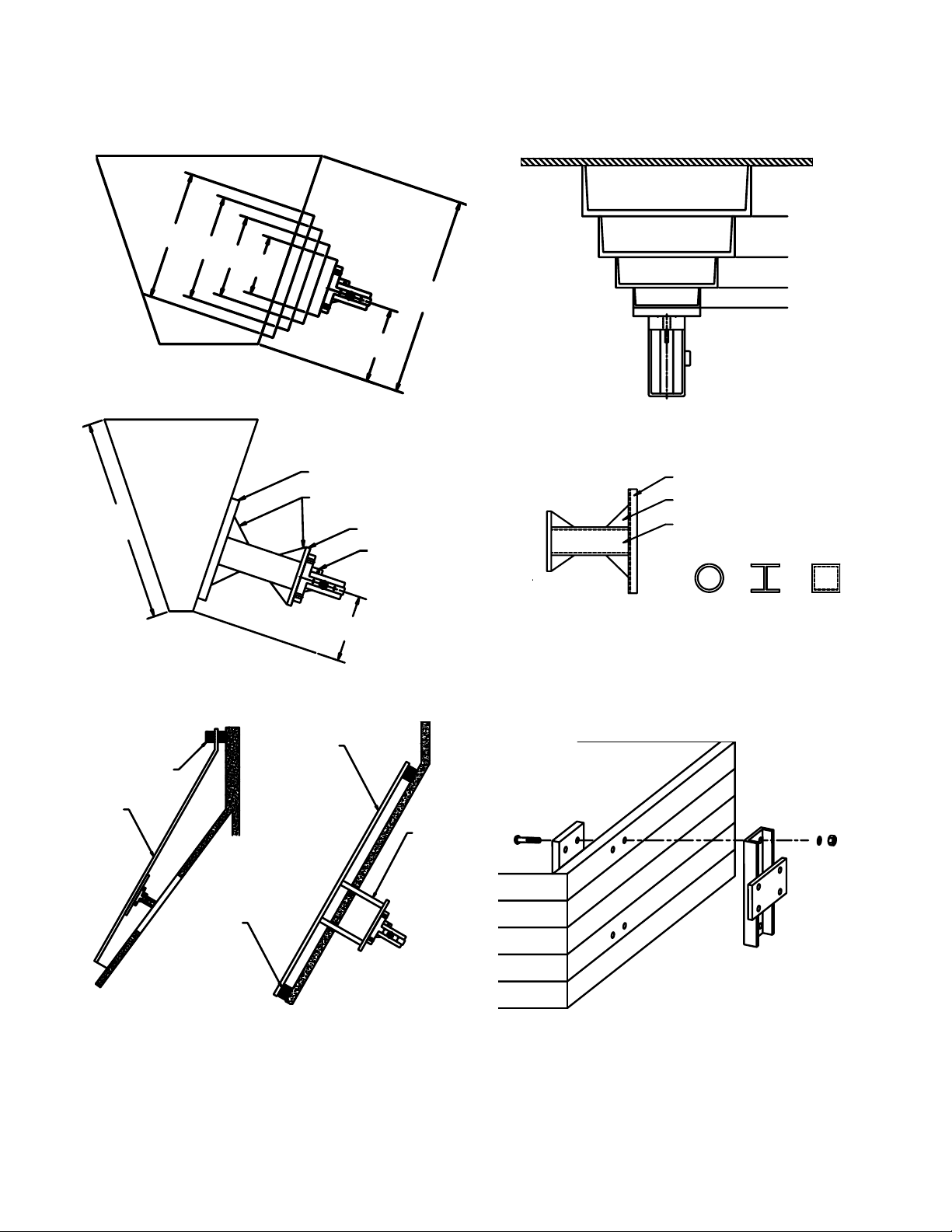

Different Suggestions for Mounting the Channel

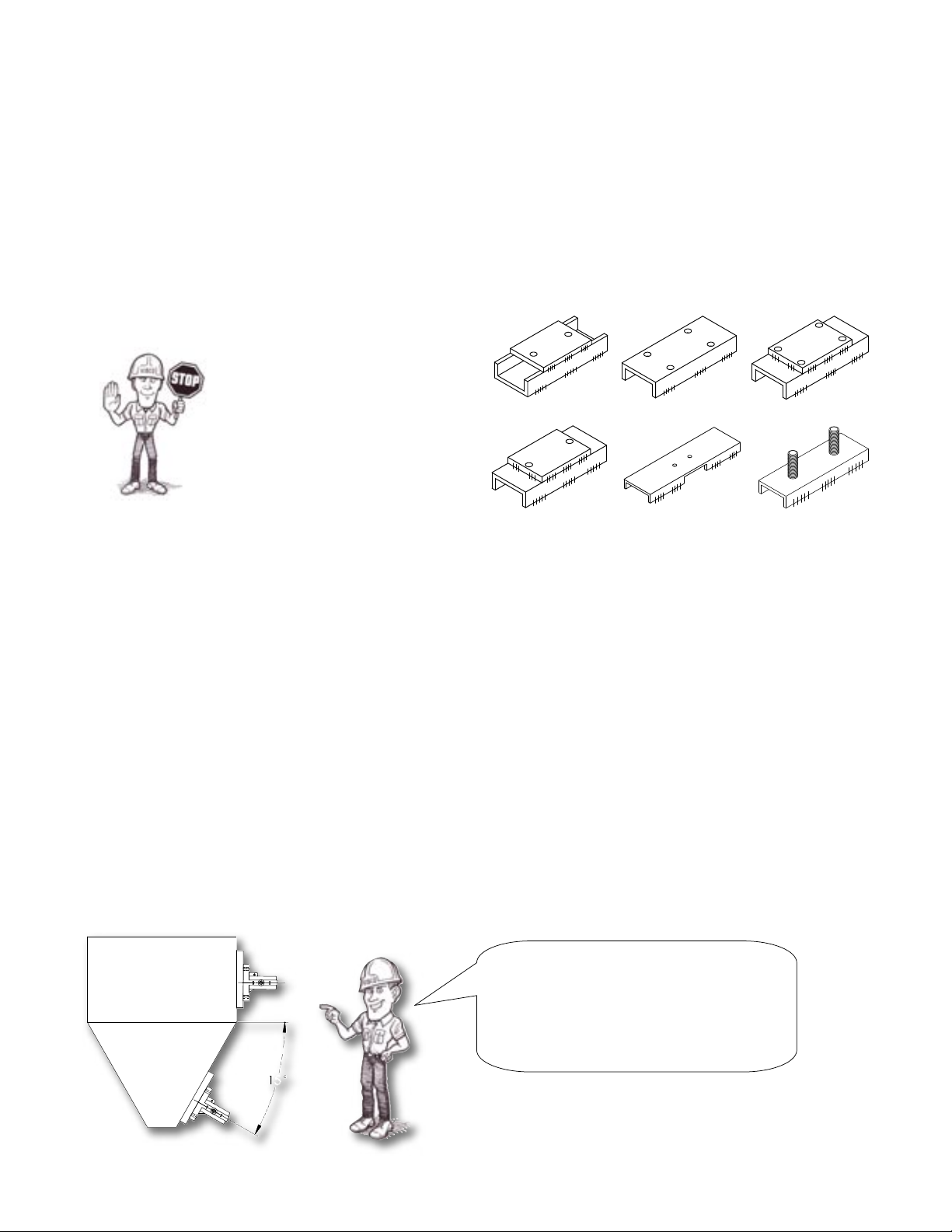

1. Mounting plate welded to legs of channel iron.

2. 3 or 4 in. channel with holes drilled thru and nuts welded on back , or just holes drilled thru.

3. Mounting channel with mounting plate and holes drilled or tapped thru.

4. Notch the channel for access to mounting bolts.

5. Weld studs to back of channel.

NOTE: for a list of alternate mounting brackets, see pg. 35 of the VIBCO General Catalog.

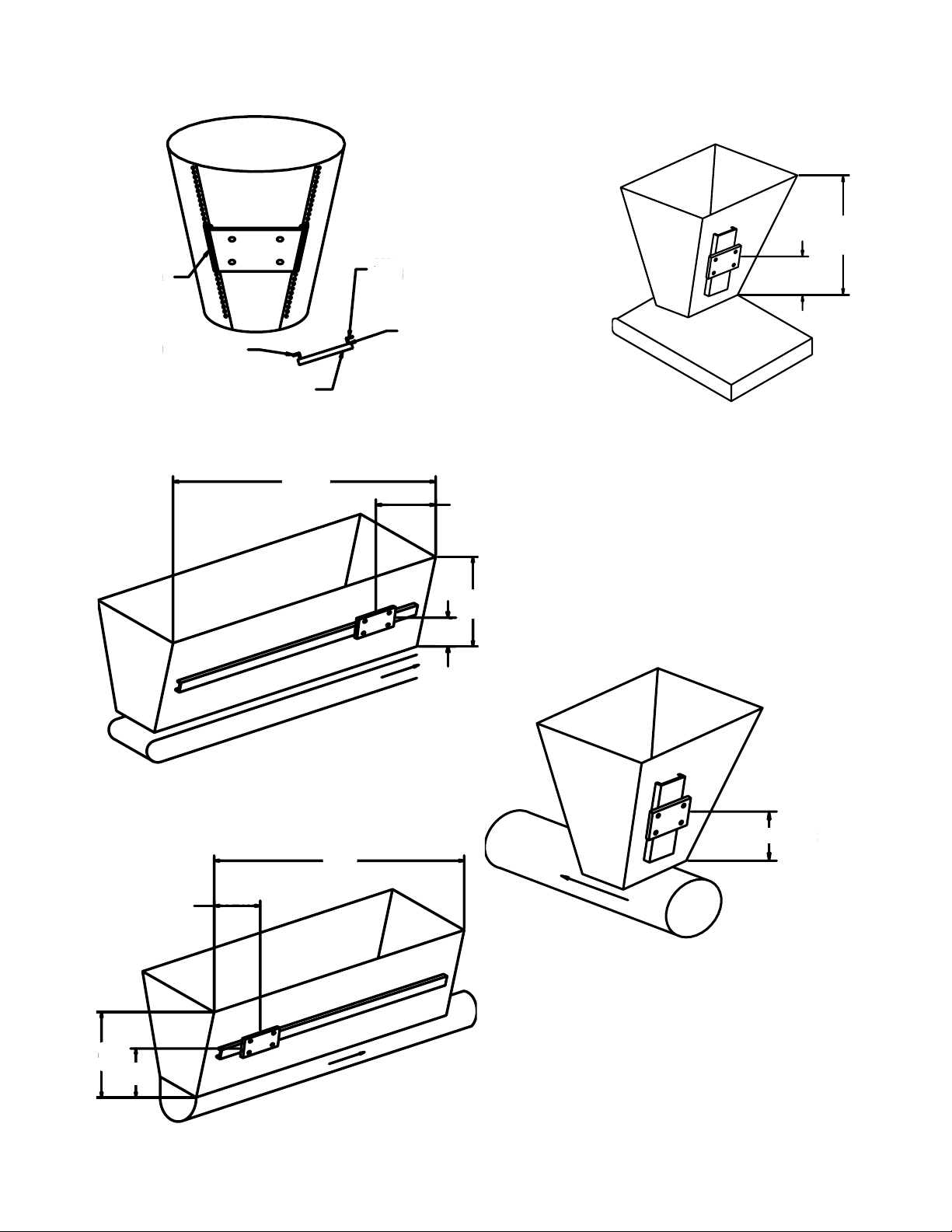

Placement

For coarse materials the vibrator should be mounted approximately 1/3 of the distance from

the discharge opening to the top of the sloped portion of the bin. For ne grain materials place

the vibrator approximately 1/4 of the same distance (see different mounting suggestions on the

following pages).

Welding Channel Iron to Bin

Where possible, the mounting plate or the channel iron should be placed 1/3 to 1/4 of the distance

from the discharge opening to the top of the sloped portion of the bin. Tack weld channel iron

in place, then weld intermittent welds 3 in. to 6 in. long with 3 in. between them along the entire

length of the channel. Stop weld a minimum of 1 in. from the ends. It is important that you do not

weld the ends of the channel iron. The heat concentration when welding the ends could cause

premature fatigue cracks.

Installing Safety Chain

It is important to install a safety chain or wire in order to prevent the vibrator from falling and

potentially causing injury if it comes loose from its mount.

1

54

3b

3a

2

4

PHONE: 1-800-633-0032 FAX: 1-401-539-2584

Always stop welds 1 in.

from ends to prevent heat

concentration and bin crack.

Stitch weld channel: weld 2 to

3 inches, skip 1 to 2 inches and

repeat until securely mounted.

Standard piston models should

be mounted at least 15 degrees

from the ground. Anything less

than 15 degrees requires a

spring (-SP) model.

Welding Mounting Plate to Channel Iron

Stitch weld the mounting plate to the middle of the channel iron. If the bin plate is 3/16 in. or

less, weld the mounting plate to the back of the channel iron (see Figure 3 or 4). If the bin plate

is over 3/16 in. weld the mounting plate to the legs of the channel iron (see Figure 1). Drill and

tap holes or use studded plate (see Figure 1 or 5). Make sure the mounting plate does not warp

or distort. If this occurs, straighten, replace it or shim vibrator.

X