UG:108 vicorpower.com Applications Engineering: 800 927.9474 Page 2

Standard Features

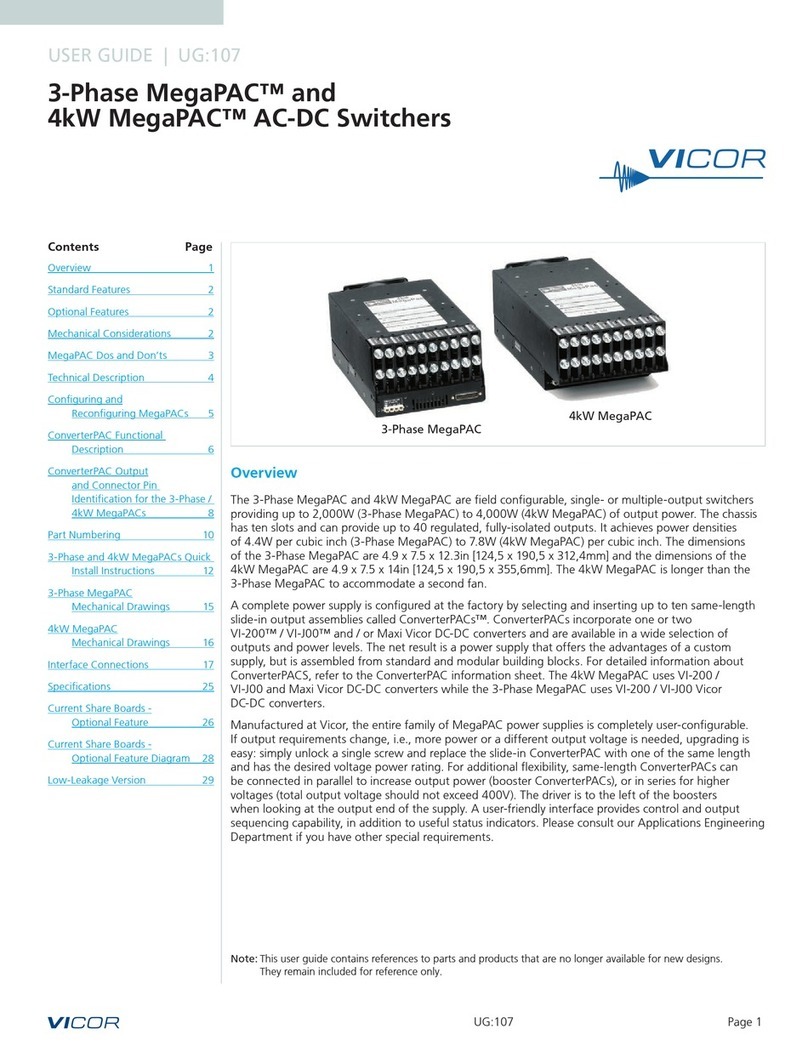

nInput: 3Æ 208/240 Vac Wye or Delta, 1Æ 180-264 (47-500Hz) or 260–352 Vdc

nPower Output: 3 Phase MegaPAC: 2,000 W with 3Æ input; 1,200 W with 1Æ input

4kW MegaPAC: 4,000 W with 3Æ input; 1,500 W with 1Æ input

n10 slots (upto 20 outputs)

nFan cooled (4kW MegaPAC-EL has 2 fans)

nFull power to 45°C; half power to 65°C

nPower Factor Correction - passive - to 0.92 PF (3Æ input)

nConducted EMI meets EN 55022 Level A

nAC Power OK and AC Power Fail status signals

nOutput Sequencing and General Shutdown

(Consult Applications Engineering for automatic sequencing circuitry.)

nAuto Sense capability Refer to page 12 and page 16 for more information on Autosense

nOvercurrent protection on all outputs

nOvertemperature limiting (not applicable with VI-J00)

nOvervoltage protection (not applicable with VI-J00 modules)

nSize: 3 Phase MegaPAC - EL: 4.9"H x 7.5"W x 15.2"L

(124,5mm x 190,5mm x 429,3mm) Extended chassis

Size: 4kW MegaPAC - EL: 4.9"H x 7.5"W x 16.9"L

(124,5mm x 190,5mm x 386,1mm) Extended chassis

nSafety Agency Approvals: cURus, cTUVus, CE Mark

Optional Features

nDC OK status signal

nOutput voltage adjustment range with built-in potentiometer

nReversed fan airflow direction

nCurrent Share Boards - see page 25

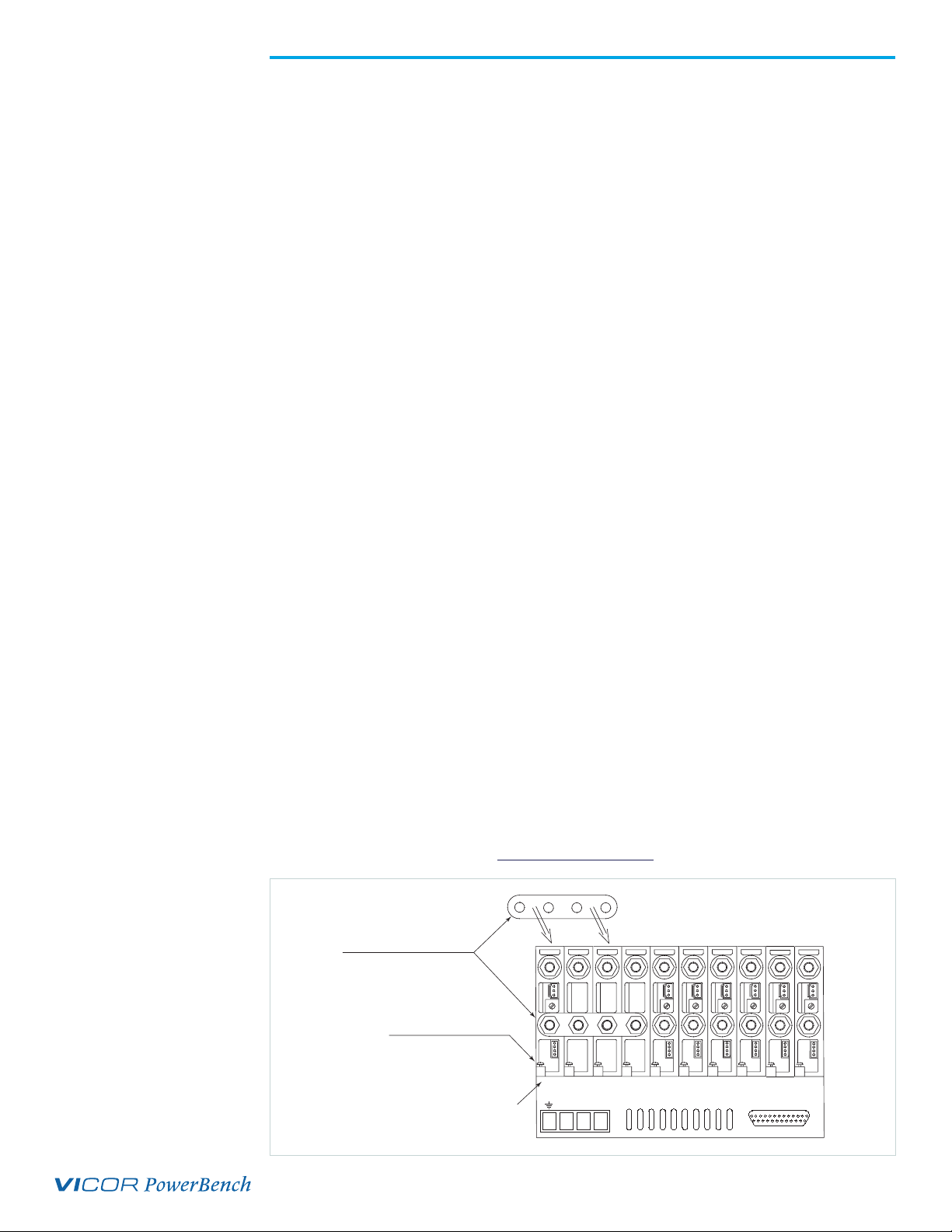

Mechanical Considerations

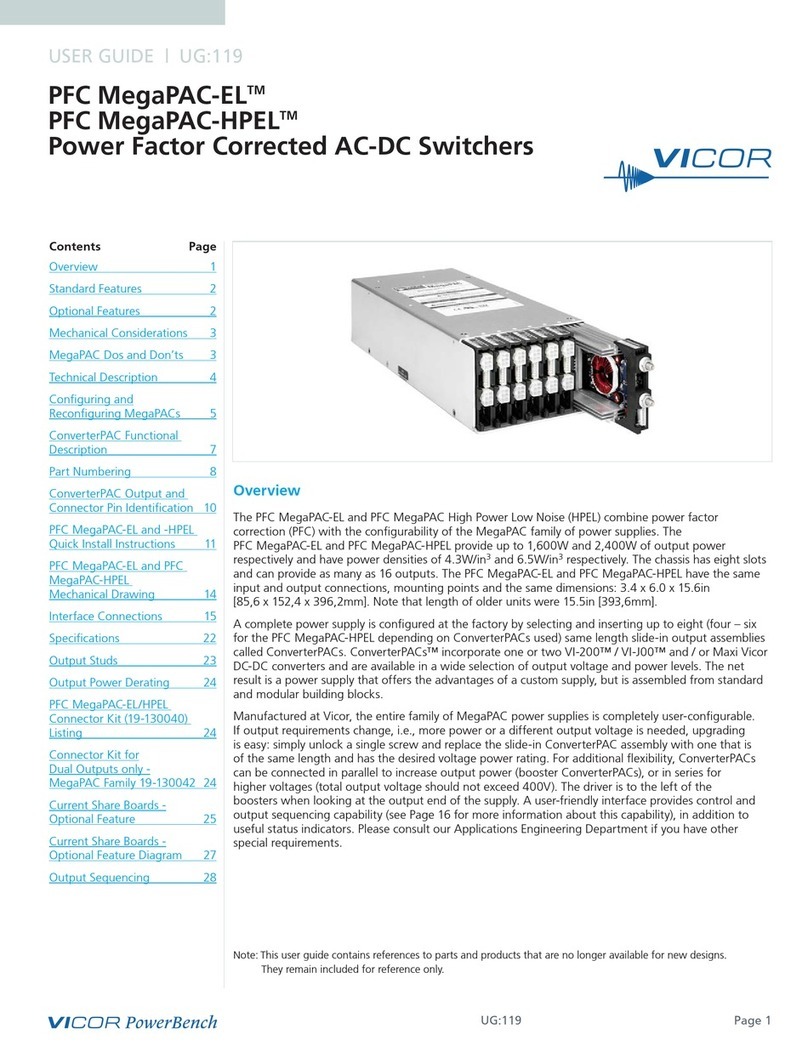

The 3 Phase MegaPAC - EL and 4kW MegaPAC - EL can be mounted on any of four

surfaces using standard 8-32 or 4mm screws. The chassis comes with four mounting

points on each surface; maximum allowable torque is 20 lb-in. The maximum

penetration is 0.15 in. (3,8mm).

When selecting a mounting location and orientation, the unit should be positioned so

air flow is not restricted. Maintain a 2" minimum clearance at both ends of the 3 Phase

MegaPAC - EL and 4kW MegaPAC - EL and route all cables so airflow is not obstructed.

The standard unit draws air in at the fan side/AC input side and exhausts air out the load

side. If airflow ducting is used, use caution, as sharp turns could present back pressure

to the 3 Phase MegaPAC - EL and 4kW MegaPAC - EL. For the 4kW MegaPAC - EL, the

fans move approximately 50 CFM of air while for the 3 Phase MegaPAC -EL, the fan

moves approximately 30 CFM of air. The 4kW MegaPAC - EL has a second fan for

additional cooling.

Avoid excessive bending of output power cables aer they are connected to the 3

Phase MegaPAC - EL or the 4kW MegaPAC - EL. For high-current outputs, use cable

ties to support heavy cables in order to minimize mechanical stress on output studs.

Be careful not to short-out to neighboring output studs. The 3 Phase MegaPAC - EL and