UG:123 Page 5

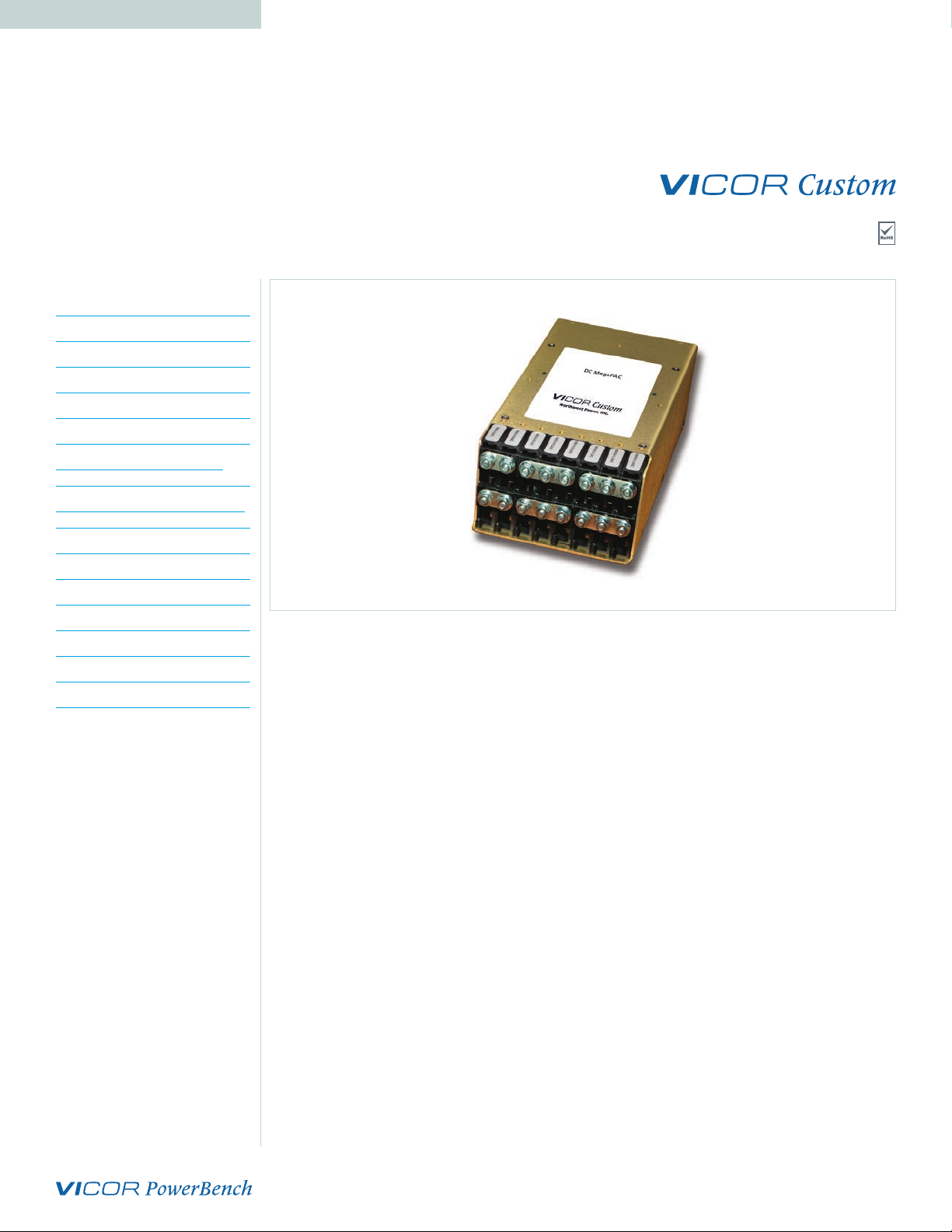

ConverterPAC™ Functional Description

ConverterPACs are the family of slide-in output assemblies used in MegaPAC™power supplies.

ConverterPACs are interchangeable within a MegaPAC so they can be added, moved or changed as

necessary. They are also interchangeable between different AC input MegaPAC chassis. A ConverterPAC

removed from a Mini MegaPAC could be used in a three-Phase MegaPAC, for example. ConverterPACs

can be selected with a variety of options and in voltages from 2 – 95VDC.

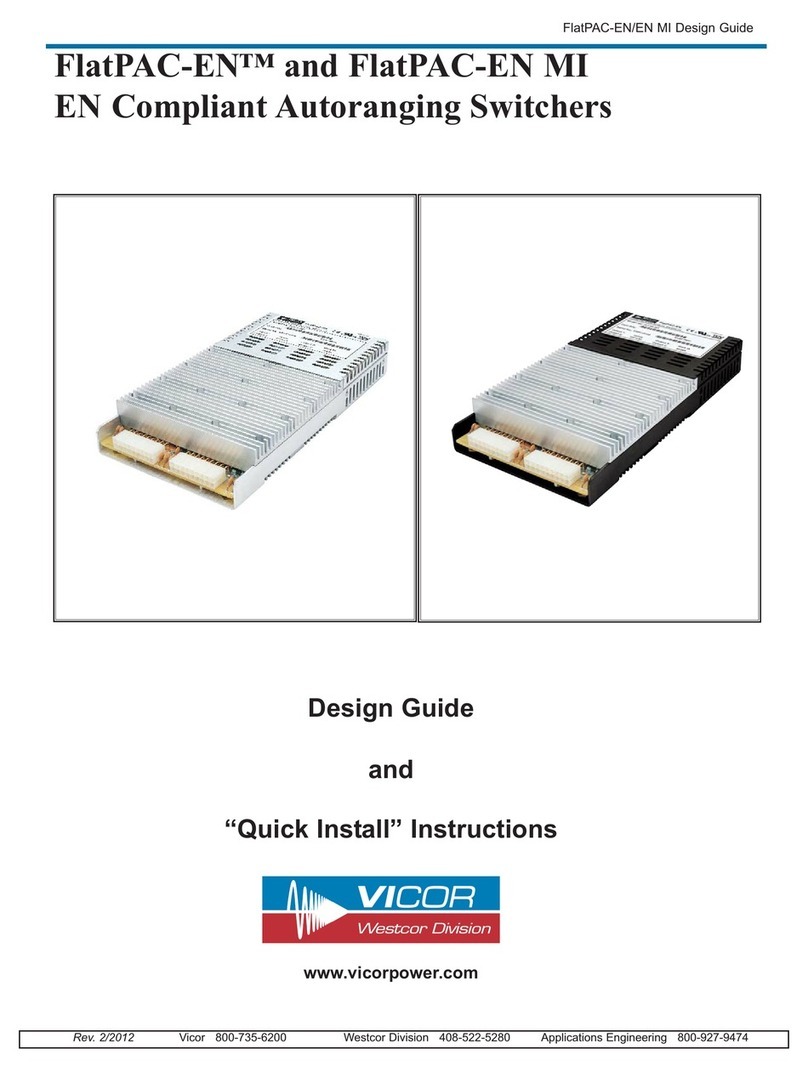

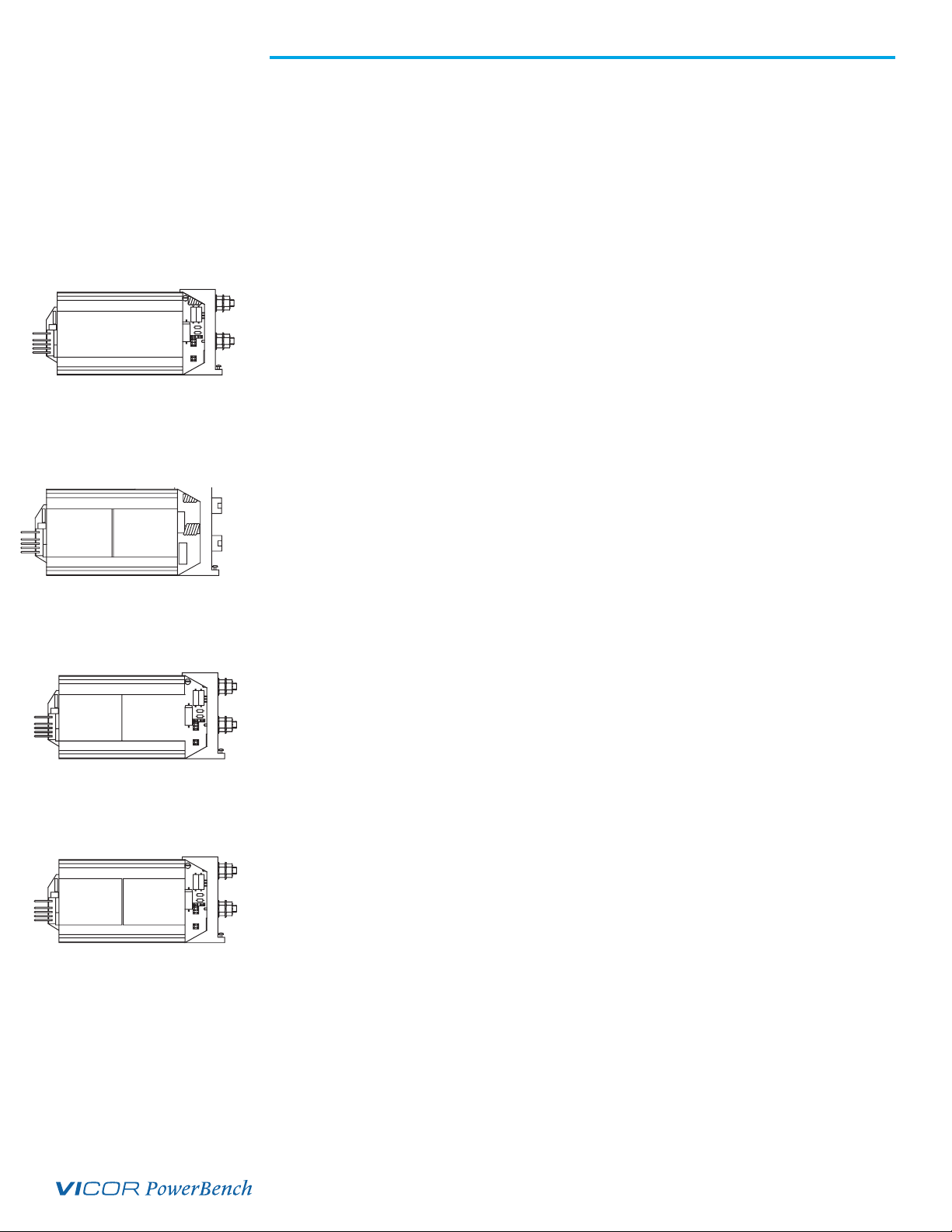

ModuPAC™

The ModuPAC output assembly consists of a VI-200 DC-DC converter that converts the high-voltage bus

to the desired regulated output voltage. Each ModuPAC can provide up to 200 watts of power. Multiple

ModuPACs can be paralleled in a driver-booster configuration to provide more power. ModuPACs are

fused with a PC-Tron, DC-rated, fast-acting fuse. A passive LC filter is used to reduce output ripple/noise

down to 1% typical, and 2% maximum peak-to-peak from 10% to 100% of rated load. An optional

DC Power Good signal or output voltage Trim potentiometer can be specified. The ModuPAC contains

overvoltage protection (OVP), overcurrent protection (OCP), and overtemperature protection (OTP). The

OCP has automatic recovery when the overcurrent condition is removed. The OVP and OTP are latching

functions and require recycling of the AC input power to restart.

DualPAC™

This output assembly consists of two VI-J00 DC-DC converters that convert the high-voltage bus to the

desired regulated output voltages. Each output on a DualPAC can provide up to 100 watts of power

and is fused with a single PC-Tron, DC-rated, fast-acting fuse. A passive LC filter is used to reduce output

ripple/noise down to 1% typical and 2% maximum peak-to-peak from 10% to 100% of rated load. An

optional output voltage trim potentiometer can be specified. DC Power Good signal is not available. The

DualPAC contains overcurrent protection, which recovers automatically when the overcurrent condition

is removed. Overvoltage and overtemperature protection are not available.

JuniorPAC™

The JuniorPAC consists of one VI-J00 DC-DC converter that converts the high-voltage bus to the desired

regulated output voltage. JuniorPACs can provide up to 100 watts of output power and are fused with

a single PC-Tron, DC-rated, fast-acting fuse. A passive LC filter is used to reduce output ripple/noise

down to 1% typical, and 2% maximum peak-to-peak from 10% to 100% of rated load. An optional

DC Power Good signal or output voltage trim potentiometer can be specified. The JuniorPAC contains

output overcurrent protection, which recovers automatically when the overcurrent condition is removed.

Overvoltage and overtemperature protection are not available.

RamPAC™

This output assembly consists of a VI-J00 DC-DC converter with a Ripple Attenuator Module (RAM) and

is designed for applications requiring low-output ripple/noise. The RamPAC can attenuate the ripple/

noise down to 10mV peak-to-peak over a 20MHz bandwidth from 10% to 100% of rated load of the

converter. Each RamPAC can provide up to 100 watts of output power, and outputs from 5 to 50V are

available. An optional DC Power Good signal or output voltage trim potentiometer can be specified. The

RamPAC contains output overcurrent protection, which recovers automatically when the overcurrent

condition is removed. Overvoltage and overtemperature protection are not available.

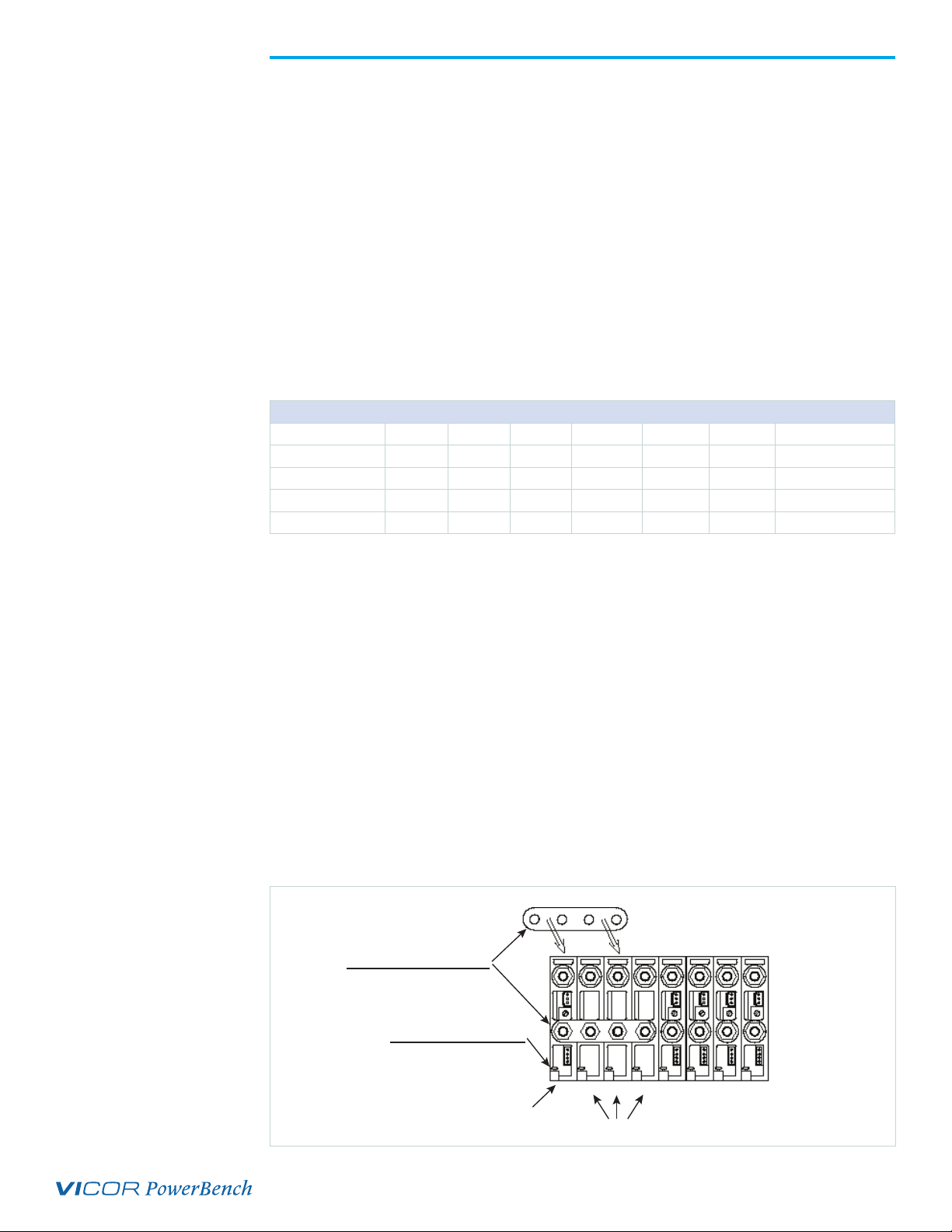

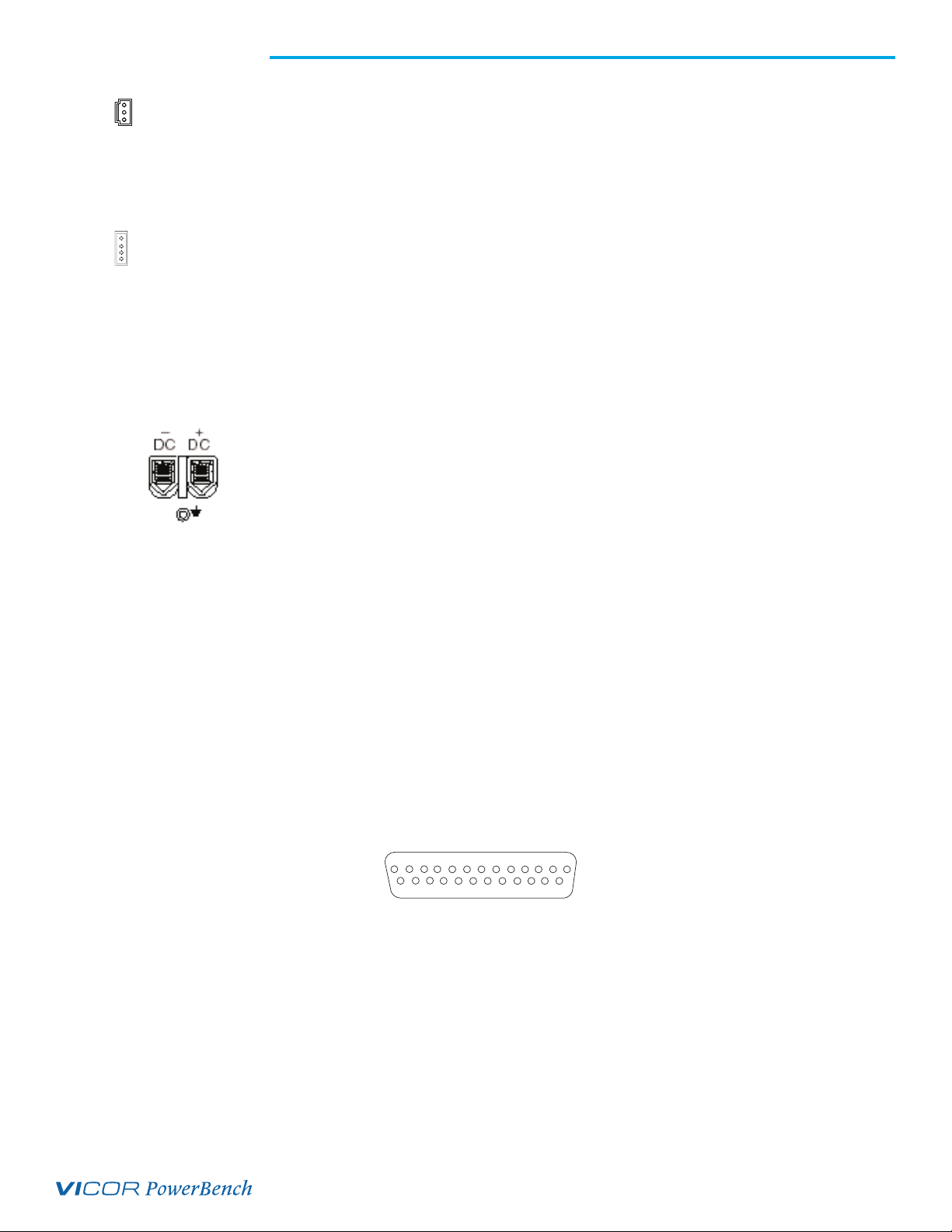

+

_

VI-200

Output Adjust

–VOUT

+VOUT

DC OK (Power Good)

VI-J00

Remote Sense

Output Adjust

–VOUT

+VOUT

DC OK (Power Good)

Remote Sense

Output #2 Adjust

Output #2

Output #1

Remote Sense

Output #1 Adjust

VI-J00VI-J00

VI-J00 RAM

Remote Sense

Output Adjust

–VOUT

+VOUT

DC OK (Power Good)

ModuPAC

JuniorPAC

DualPAC

RamPAC