UG:105 vicorpower.com Applications Engineering: 800 927.9474 Page 4

nAvoid running input and output wiring in close proximity as this may cause noise

related problems.

nPFC MegaPACs are NOT user serviceable. Please contact our customer service

department at 1-800-735-6200 for repair assistance. Please be advised that attempts

to repair or modify the power supply will void the warranty.

nA proper fault protection device (fuse or breaker) should be used in series with

the input terminals.

nUse proper size wires to avoid overheating and excessive voltage drop.

nNEVER loosen the inner nut on a ConverterPAC.

nFinPAC ConverterPACs can only be used with a high power chassis. A high power

chassis is identified by an “MX” prefix code in the specific model number.

nOutput voltages over 60 Vdc, whether from individual modules or series arrays, are

considered as hazardous secondary outputs under UL 60950. Appropriate care must

be taken in design implementation of the supply.

Technical Description

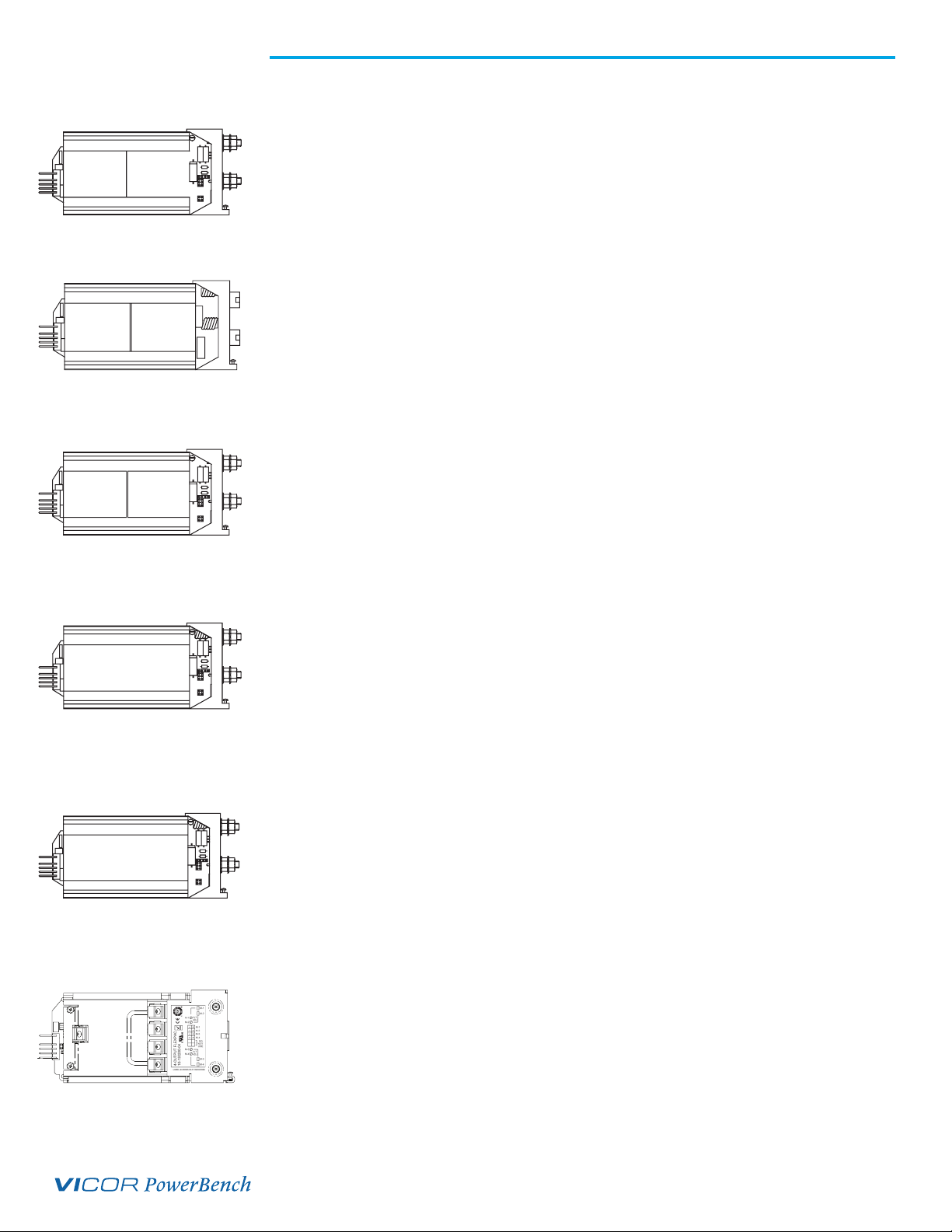

The PFC MegaPAC chassis consists of an o-line single phase, power-factor-corrected

front end, EMI filter, cooling fan, customer interface and associated housekeeping

circuits. Input AC mains voltage (L1, L2 and GND) is applied to a terminal block. The

input current is passed through an EMI filter designed to meet conducted noise limit “B”

specifications of FCC Part 15, VDE 0871, and EN55022 class A At start-up, inrush current

is limited by a PTC thermistor. The PTC is shunted out shortly aer initial power-up by

a DC bus voltage Sense circuit driving a relay. Aer rectification, the input voltage is put

through a boost converter that keeps the AC input current sinusoidal and synchronized

with the AC input voltage (in compliance with EN61000). The boost converter delivers

regulated high voltage DC to the hold-up capacitors and backplane. The backplane

supplies power to a variety of ConverterPAC assemblies that provide the desired

regulated outputs.

Voltage conversion in the output assemblies is achieved by Vicor’s family of

Zero-Current-Switching (ZCS) DC to DC converters. These are forward converters in

which the main switching element switches at zero current. This patented topology has

a number of unique attributes: low switching losses; high frequency operation resulting

in reduced size for magnetics and capacitors; excellent line and load regulation; wide

adjustment range for output; low EMI/RFI emissions and high eciencies.

At initial power-up the PFC MegaPAC outputs are disabled to limit the inrush current

and to allow the DC bus potential to settle out to the correct operating level. A low-

power flyback converter operating with PWM current-mode control converts the

high voltage DC bus into regulated low voltage to power the internal housekeeping

circuits and DC cooling fan. The internal housekeeping Vcc comes up within 2 s aer

the application of input power. Once the high voltage bus is within its limits, the AC

OK signal asserts to a TTL “1” indicating the input power is OK, and enables the power

outputs. An auxiliary Vcc output of 5 Vdc sourcing up to 0.3 A is provided for

peripheral use.

An output Enable/Disable function is provided by using an optocoupler to control

the Gate In pins of the ConverterPAC assemblies. If the Enable/Disable control pin is

pulled low, the optocoupler turns on, pulling the Gate In pin low and disabling the

ConverterPAC output. The nominal delay for an output to come up when measured

from release of the Enable/Disable pin is 10-15 ms. The General Shutdown function

controls all outputs simultaneously and works in a similar manner.