UG:115 Page 8

Sense Connections

Note: PFC Mini™ units built after 12/2000 have been equipped with a feature called Autosense. If no sense

connections are made, the PFC Mini will automatically operate in local-sense mode. If remote-sense connections are

made, the PFC Mini will operate in a remote-sense mode.

For units built before 12/2000 (units without Autosense), Sense connections must ALWAYS be made.

Not connecting Sense Lines to their respective outputs can cause failure to the unit.

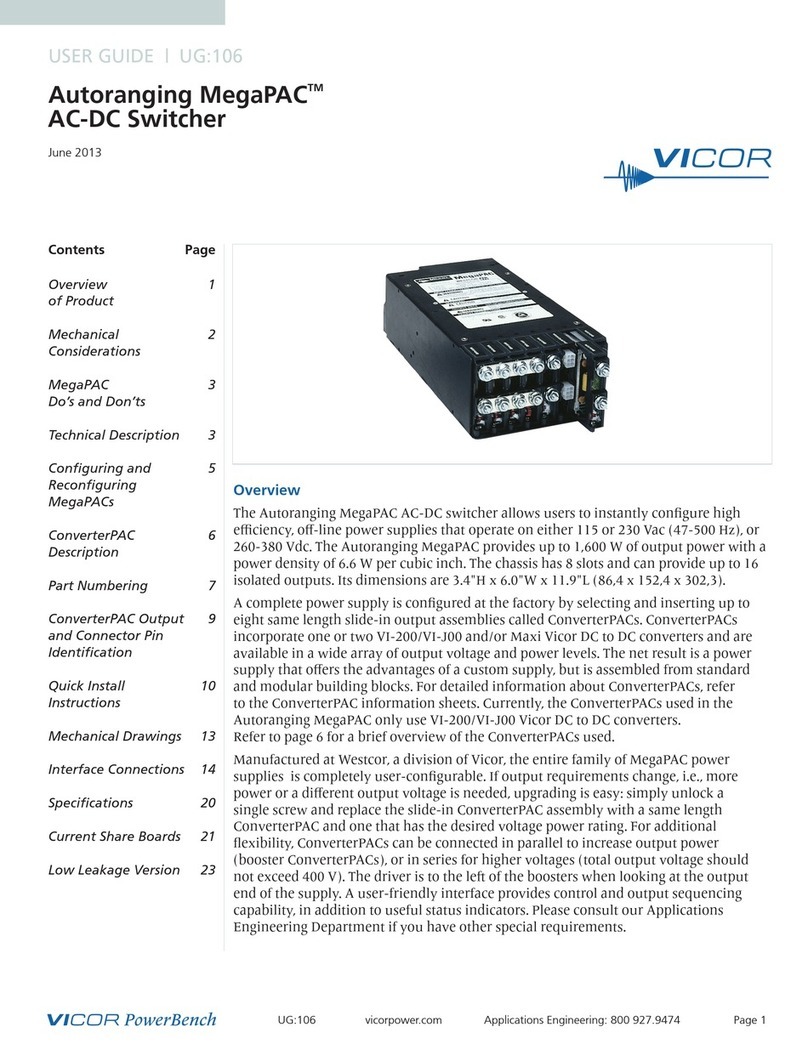

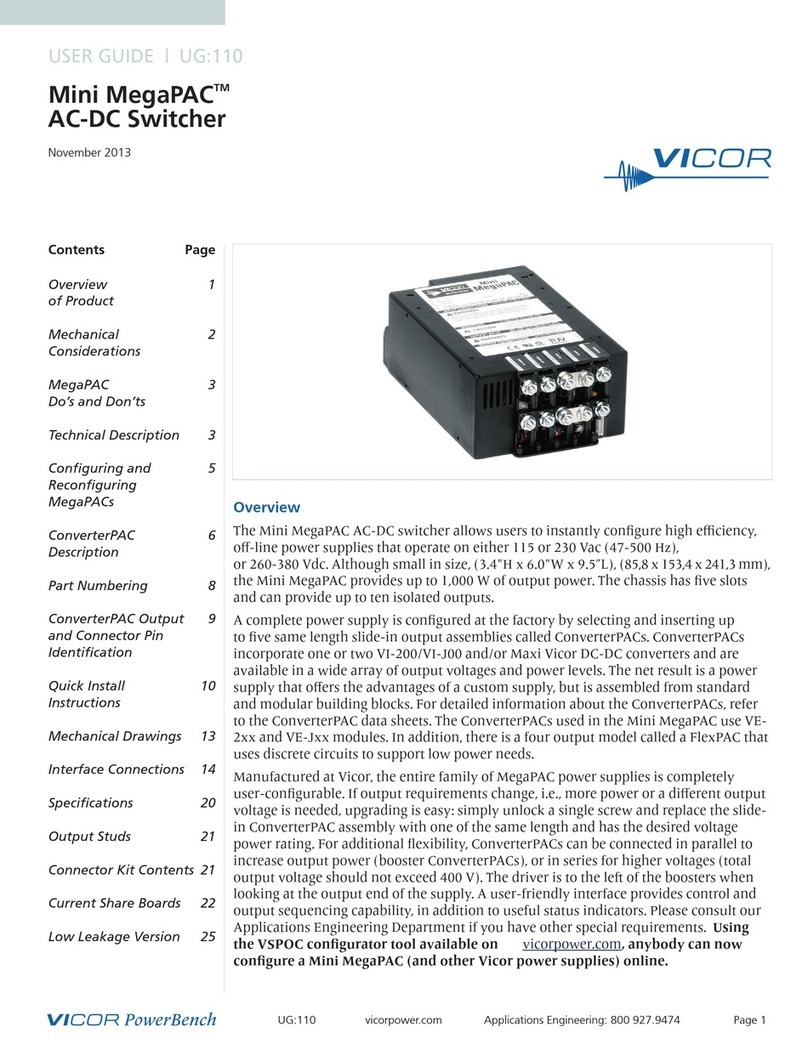

Sense connections on output connections with studs

PFC Minis are currently shipped with Autosense installed. Those without the Autosense were shipped

with local sense installed. (See note on Page 13)

If remote sense is desired, remove jumpers MBJ1 and J3, located behind the sense connector.

Connector pin SxJ2-2 is the +SENSE and SxJ2-3 is the –SENSE.

Use Molex mating receptacle #50-57-9403 with #16-02-0103 terminals.

Attach terminals to 20 – 22AWG stranded twisted pair wire using Molex tool #11-01-0208.

Attach opposite end of sense lines to point where regulation is desired.

Verify that sense lines are not cross-connected.

Sense connections on output connection with Molex connectors

PFC Minis are currently shipped with Autosense installed. Those without the Autosense were shipped

with local sense installed. (See note on Page 13)

If remote sense is desired, remove jumpers on MBJ1 and J3, located on either side

of the output connector.

Connector pin SxJ1-4 is the +SENSE and SxJ1-5 is the –SENSE for output #1.

SxJ1-13 is the +SENSE and SxJ1-15 is the –SENSE for output #2.

Use Molex mating receptacle #39-01-2180 with #39-00-0039 terminals.

Attach 18 – 24AWG stranded twisted pair wire using Molex tool #11-01-0197.

Trim Connections

Trim connections on outputs with studs:

SxJ2-1 provides trim access.

Use Molex mating receptacle #50-57-9403 with #16-02-0103 terminals.

Attach 20 – 22AWG stranded wire using Molex tool #11-01-0208.

Trim connections on outputs with Molex connectors:

SxJ1-14 provides trim access for output #1, and SxJ1-6 provides trim access for output #2.

Use Molex mating receptacle #39-01-21 with #39-00-0039 terminals.

Attach 18 – 24AWG stranded wire using Molex tool #11-01-0197.

Interface Connections

J3-1 to 3 are Enable/Disable for cards 1-3, respectively.

J3-4 is Signal Ground, J3-5 is +5V, J3-6 is AC Power OK, and J3-7 is General Shutdown.

Use mating receptacle AMP P/N 205204-4 with terminals AMP P/N 66506-9.

Attach terminals to 18 – 24AWG stranded wire.

Remove jumpers for

Remote Sense

Remove jumpers for

Remote Sense on

Output # 1

Remove jumpers for

Remote Sense on

Output # 2

Connector J2

1

2

3

Trim Pin Access

+SENSE

–SENSE

Pin

SxJ2

J3-9 SPARE

J3 INTERFACE PIN OUT

J3-1

J3-2

J3-3

J3-4

J3-5

J3-6

J3-7

J3-8

E/D-1

E/D-2

E/D-3

SIGNAL GROUND

VCC +5V 300mA

ACOK AC POWER OK

GSD GENERAL SHUTDOWN

SPARE

J3 INTERFACE CONNECTION

MATING HDWR:

HOUSING: AMP P/N 205204-4

SCREW LOCK: AMP P/N 205980-4

TERMINALS: AMP P/N 66506-9

CRIMP TOOL: AMP 58448-3

SxJ1 Dual Output connector

T

T

+S

12

3

45

67

8

9

10

1112

13

14

15161718

+

-

-

-S

+

+-

++-

+S

-S+-

-

M1 Output

M2 Output

Locking Key

Pin 1 Identifier