UG:106 vicorpower.com Applications Engineering: 800 927.9474 Page 3

MegaPAC Do’s and Don’ts

nFor units without Autosense, do not leave ConverterPAC Sense lines open. Always

terminate them to their respective output locally or at the load. If ConverterPAC

has Autosense, no local sense connection is required. See page 11 and page 14 for

more information on Autosense.

nIf needed, use Connector Kit # 19-130040 for the Autoranging MegaPAC.

nAlways fill all output slots of the MegaPAC. If a slot is not filled with a

ConverterPAC, it should be filled with an airblock. Airblocks are plastic assemblies

whose main function is to fill up an empty slot. Any airflow escape from an empty

slot significantly degrades thermal performance, and can result in overheating and

damage to the power supply.

nDo not unplug ConverterPACs while input power is applied.

They are not designed for hot-plug applications.

nDo not restrict airflow to the unit. The cooling fan draws air into the unit and forces it

out at the output power terminals.

nFor power expansion use booster ConverterPACs. Viewing the unit from the output

terminal side, always insert boosters to the right side of the driver.

nDo not use boosters as independent outputs.

Disconnecting bus bars will damage booster ConverterPACs.

nFor booster arrays, do not remove busbars.

nAlways ensure that output hex-nuts are properly torqued before applying

power to supply.

nRun the output (+/–) power cables next to each other to minimize inductance.

nWait 5 minutes aer shutting o power before inserting or removing ConverterPACs.

nDo not attempt to repair or modify the power supply in any manner other than

the exchange of ConverterPACs as described in this Design Guide.

There are no user serviceable components.

nInsert proper fault protection at power supply input terminals (i.e., a fuse).

nUse proper size wires to avoid overheating and excessive voltage drop.

nNever loosen the inner nut on a ConverterPAC.

nVerify output nuts are tight before powering up.

Technical Description

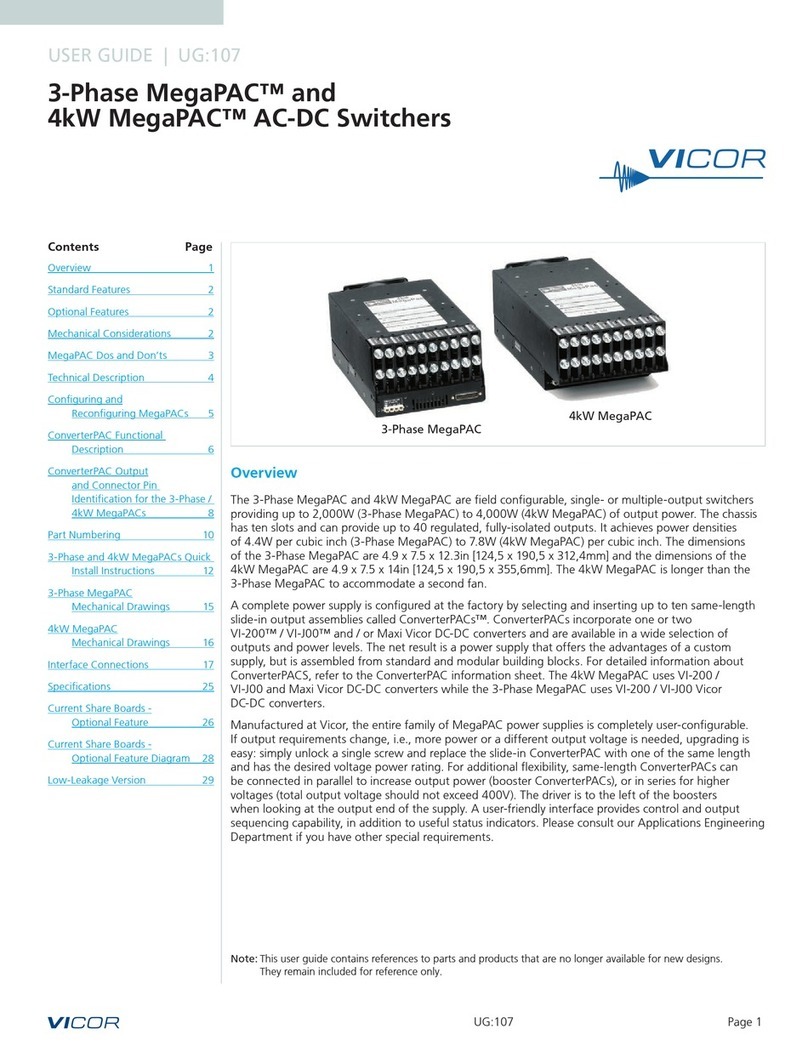

The Autoranging MegaPAC chassis consists of an o-line single phase AC front end, EMI

filter, cooling fan, customer interface and associated housekeeping circuits. Input AC

mains voltage (L1, L2/N and GND) is applied to a terminal block. The input current is

passed through an EMI filter designed to meet conducted noise limit "A" specifications

of EN55022, Level A. At start-up, inrush current is limited by an NTC thermistor prior

to being passed to the power rectifiers. The thermistor is shunted out shortly aer

initial power-up using a DC bus voltage Sense circuit and a relay. The sense circuit also

controls the input autoranging selection relay. The power rectifiers and filter capacitors

are arranged in a conventional full wave bridge rectifier/voltage doubler configuration.

This operates as a full wave bridge rectifier on 230 Vac, and voltage doubler on 115 Vac,

delivering unregulated 300 Vdc to a high voltage backplane. The backplane supplies

power to a variety of ConverterPAC assemblies that provide the desired low voltage,

regulated outputs.