victaulic.com

10.95 8507 Rev AUpdated 11/2015 © 2015 Victaulic Company. All rights reserved.

ALWAYS REFER TO ANY NOTIFICATIONS AT THE END OF THIS DOCUMENT REGARDING PRODUCT INSTALLATION, MAINTENANCE OR SUPPORT.

1.0 PRODUCT DESCRIPTION

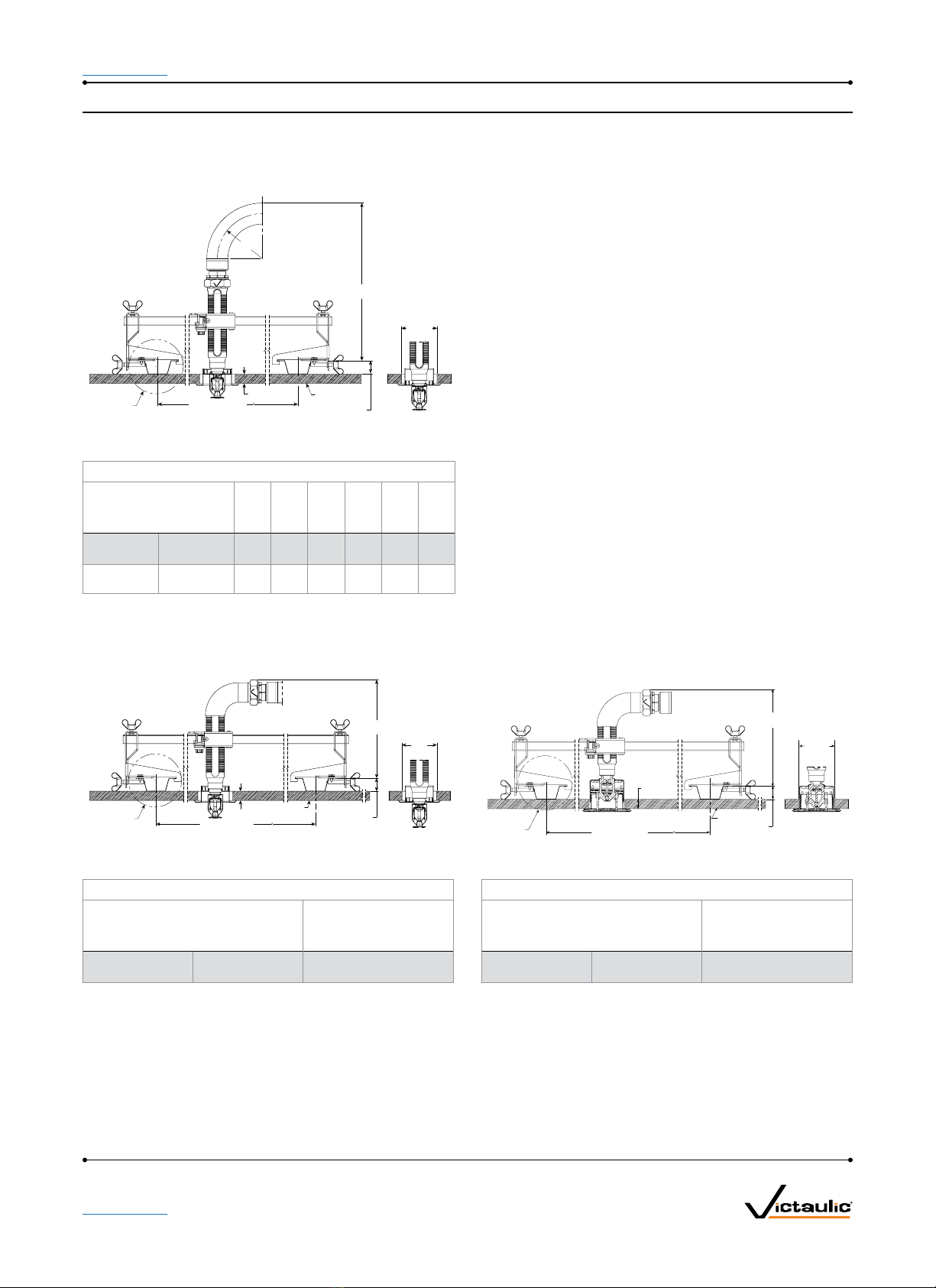

Available Sizes by Component

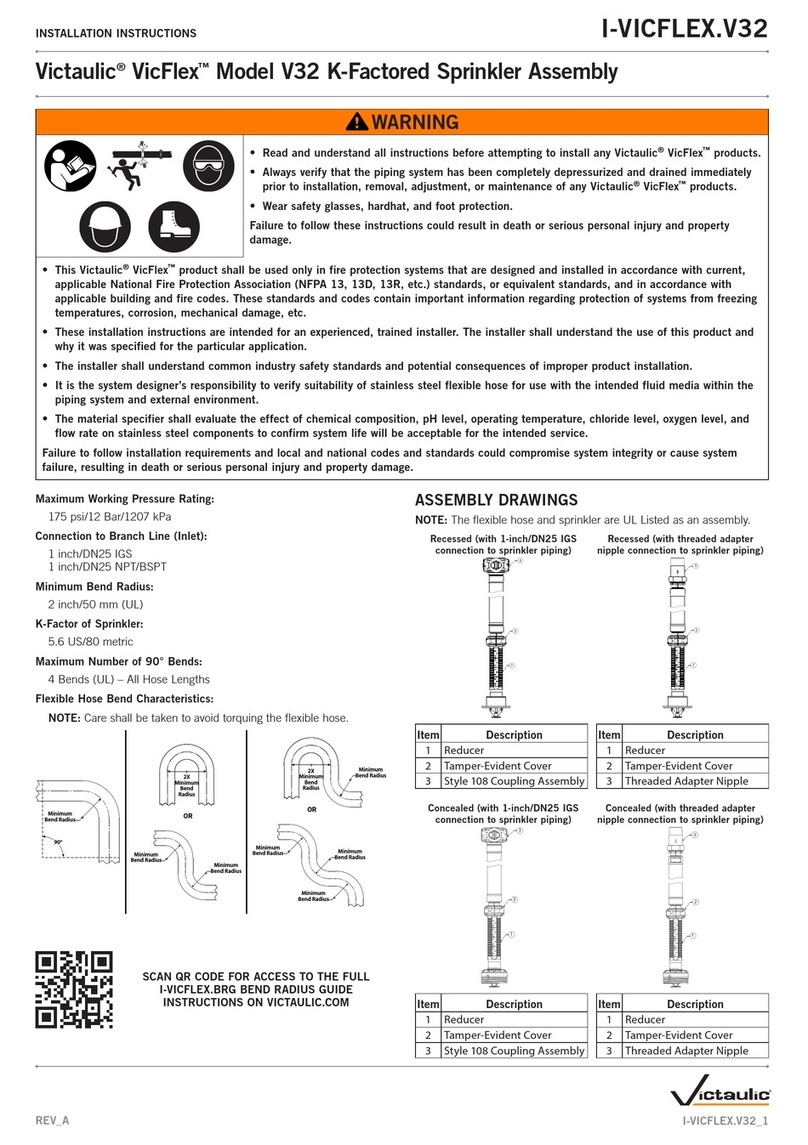

• Series AH1 Braided Hose: 31, 36, 48, 60, 72"/790, 914, 1220, 1525, 1830 mm. Note: length includes adapter

nipple and 5.75"/140 mm straight reducer.

• Sprinkler Reducers: ½" and ¾"/15 and 20 mm sprinkler connections and 5.75"/140 mm, 9"/230 mm, 13"/330 mm

straight lengths and short, long 90º elbows. Note: The short 90° elbow is typically used with concealed sprinklers

while the long 90º elbow is typically used in the installation of recessed pendent sprinklers.

• Adapter Nipples: 1"/25 mm NPT or BSPT adapter nipples for attaching to pipe and fittings outlined in NFPA

standards. ¾"/20 mm NPT or BSPT available for VdS. 1 ¼"/ 32mm BSPT available for LPCB.

• Brackets:

• Style AB1 for suspended and hard-lid ceilings, allows installation before ceiling tiles in place

• Style AB2 for suspended and hard-lid ceilings, allows for vertical sprinkler adjustment, and installation before

ceiling tiles in place

• Style AB3 for surface mount applications, wood, metal and block walls

• Style AB4 for hard-lid ceilings with hat furring channel grid systems, allows for vertical sprinkler adjustment

• Style AB6 for cold storage applications, refer to submittal 10.90

• Style AB7 for suspended and hard-lid ceilings

• Style AB7 Adjustable for suspended and hard-lid ceilings

• Style AB8 for hard-lid ceilings with CD 60/27 profile metal studs (regionally available)

• Style AB9 for hard-lid ceilings with hat furring channel grid systems

• Style AB10 for Armstrong®TechZone™ceilings

Maximum Working Temperature

• 225°F/107°C

Maximum Working Pressure

• 200 psi/1375 kPa (FM Approval)

• 175 psi/1206 kPa (cULus Listed)

• 1600 kPa/232 psi (VdS/LPCB Approved)

Victaulic®Vic-Flex™ Sprinkler Fittings

Series AH1 Braided Flexible Hose 10.95

1

System No. Location

Submitted By Date

Spec Section Paragraph

Approved Date