10.90 2870 Rev M Updated 04/2022 © 2022 Victaulic Company. All rights reserved.

victaulic.com

User Responsibility for Product Selection and Suitability

Each user bears final responsibility for making a determination as to the suitability of

Victaulic products for a particular end-use application, in accordance with industry

standards and project specifications, and the applicable building codes and related

regulations as well as Victaulic performance, maintenance, safety, and warning

instructions. Nothing in this or any other document, nor any verbal recommendation,

advice, or opinion from any Victaulic employee, shall be deemed to alter, vary, supersede,

or waive any provision of Victaulic Company's standard conditions of sale, installation

guide, or this disclaimer.

Intellectual Property Rights

No statement contained herein concerning a possible or suggested use of any material,

product, service, or design is intended, or should be constructed, to grant any license

under any patent or other intellectual property right of Victaulic or any of its subsidaries or

affiliates covering such use or design, or as a recommendation for the use of such

material, product, service, or design in the infringement of any patent or other intellectual

property right. The terms “Patented” or “Patent Pending” refer to design or utility patents

or patent applications for articles and/or methods of use in the United States and/or other

countries.

Note

This product shall be manufactured by Victaulic or to Victaulic specifications. All products

to be installed in accordance with current Victaulic installation/assembly instructions.

Victaulic reserves the right to change product specifications, designs and standard

equipment without notice and without incurring obligations.

Installation

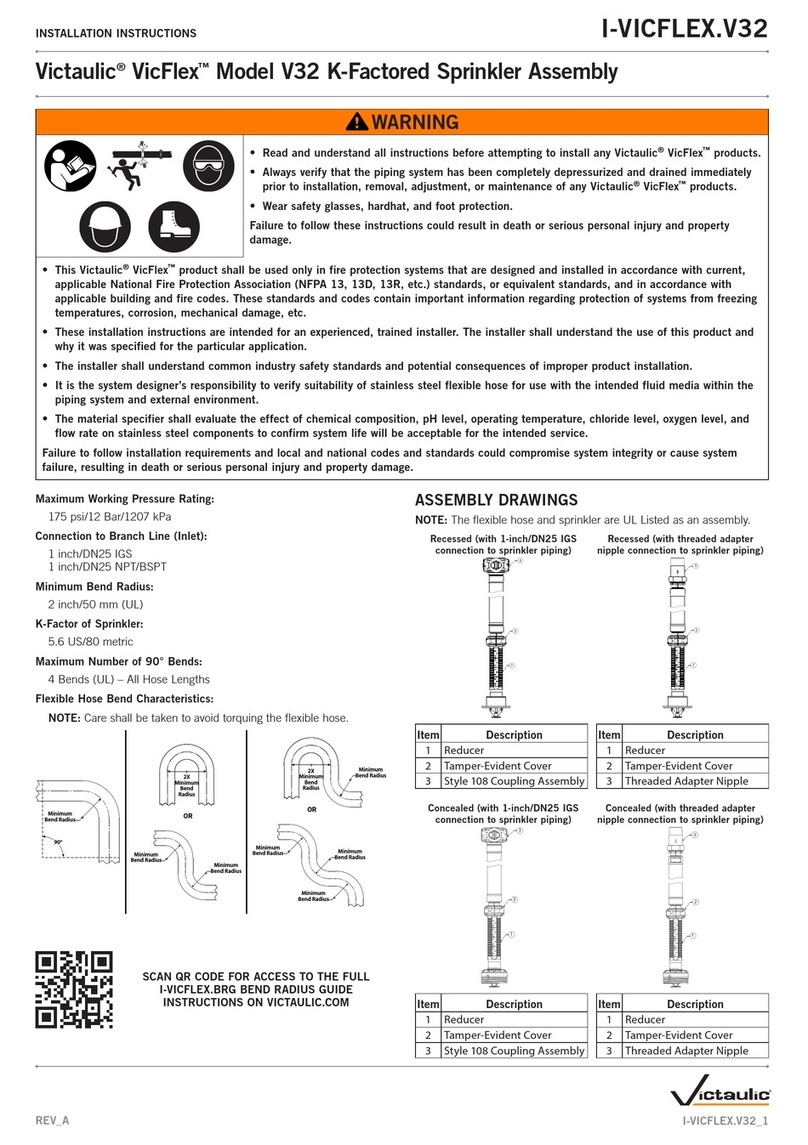

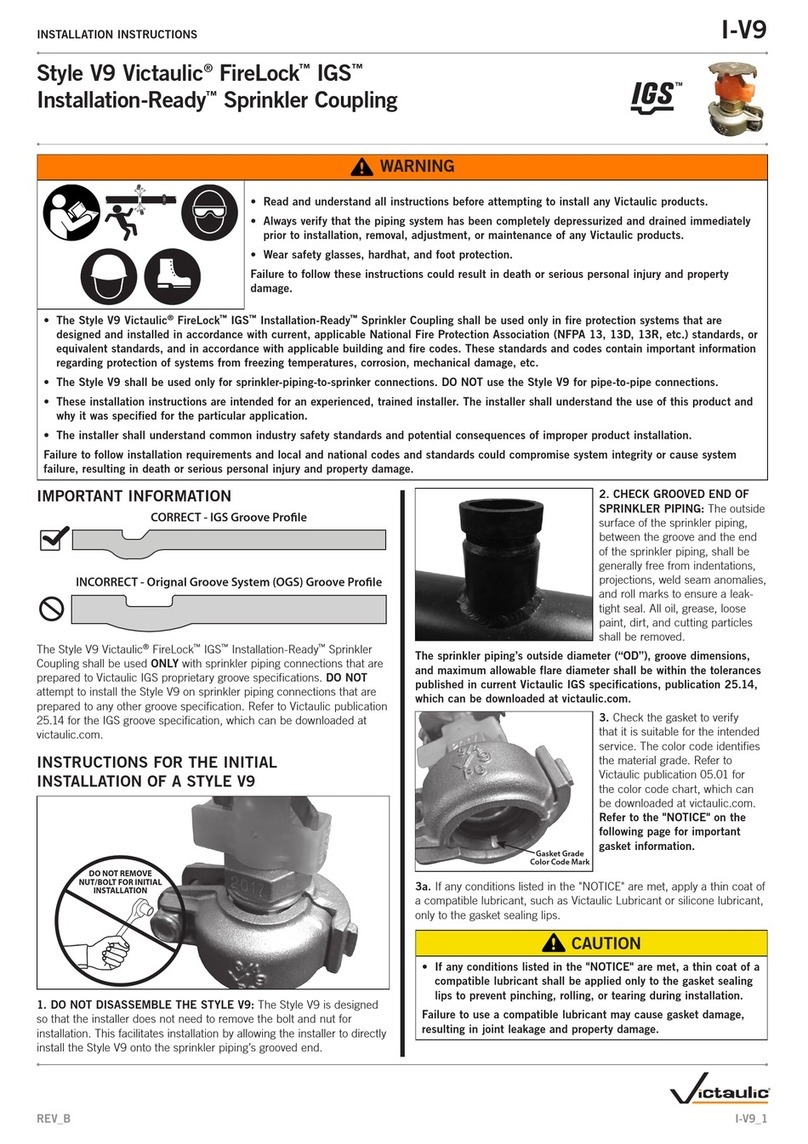

Reference should always be made to I-VICFLEX-AB1-AB2-AB10, I-VICFLEX-AB4,

I-VICFLEX-AB7, or I-VICFLEX-AB8 for the product you are installing. Handbooks are

included with each shipment of Victaulic products for complete installation and assembly

data, and are available in PDF format on our website at www.victaulic.com.

Warranty

Refer to the Warranty section of the current Price List or contact Victaulic for details.

Trademarks

Victaulic

and all other Victaulic marks are the trademarks or registered trademarks of

Victaulic Company, and/or its affiliated entities, in the U.S. and/or other countries.

7.0 REFERENCE MATERIALS (CONTINUED)

VicFlex™Style AB6 Bracket

SF-DRYSPRINKLERS 17227 REV D 01/2022

© 2022 VICTAULIC COMPANY. ALL RIGHTS RESERVED.

VICFLEX™STYLE AB6 ASSEMBLY DRY SPRINKLER ORDER FORM

SHIP TO:

Name: Date of Order:

Address: Purchase Order:

Ship Via:

City: Tag:

State/Prov.: Signature*:

Zip/Postal Code:

PART CODE CONFIGURATOR: Configure the part code with options from chart below. DO NOT circle pipe order lengths. Input appropriate length and quantity for each

in the chart below. Please attach additional forms if extra ordering space is needed. Separate forms must be completed for each configuration ordered.

Class Style Connection Deflector Temperature Response K-Factor Sprinkler

Finish

Escutcheon

Finish

Sprinkler

Barrel

Length

Escutcheon

Style

Bracket

Style

Hose

Style

Hose

Length

A = VicFlex™33 = V33 1

(Concealed)

36 = V36

(Std. Pendent/

Horizontal

Sidewall)

40 = V40 2

(Std. Pendent)

3= 1" NPT B= Std.

Pendent

C= Horizontal

Sidewall 3

P= Concealed

C= 155°F/68°C

F= 200°F/93°C

J= 286°F/141°C

Q= Quick

S= Standard

4= 5.6K

5= 8.0K

6= 11.2K

2= Chrome

4= White

(RAL 9010)

B= Black

N= VC-250 4

0= Painted

Cold Rolled

Steel, Finish

Matches

Sprinkler

Finish

X= Stainless

Steel

W= White

(RAL 9010)

Painted

Stainless Steel

120 = 12"

180 = 18"

240 = 24"

300 = 30"

11 = Flush

12 = Recessed

13 = Sleeve

& Skirt

15 = Concealed

17 =

Interchangeable

Escutcheons

5

UB6 = AB6 2= AH2

(NPT)

3= AH2

(BSPT)

8= AH2-CC

(Captured

Coupling)

4= 48"

Total Sprinklers with

specs identical to part code

configuration above

A 3 4UB6

1V33 Sprinkler only available with Escutcheon Finish 0(Painted Cold Rolled Steel, Finish Matches Sprinkler Finish),

and Escutcheon Style 15 (Concealed).

2 V40 Sprinkler only available with Deflector B(Standard Pendent), K-Factor 6(K11.2), and Sprinkler Finish 4(White RAL 9010) and N(VC-250).

3 Horizontal Sidewall not available with interchangeable escutcheons.

4VC-250 coating is only available with stainless steel escutcheons. UL and FM approved corrosion resistant coating, and VdS and LPCB recognized

and approved alternate coating. Appears chrome in color. Not available with concealed sprinklers.

5Only available with pendent sprinklers; Sleeve and Skirt, Recessed and Flush escutcheons included with a plain barrel sprinkler.

* I agree to purchase the dry sprinklers specified on this form, which are NON-RETURNABLE & NOT CANCELLABLE.

9

victaulic.com